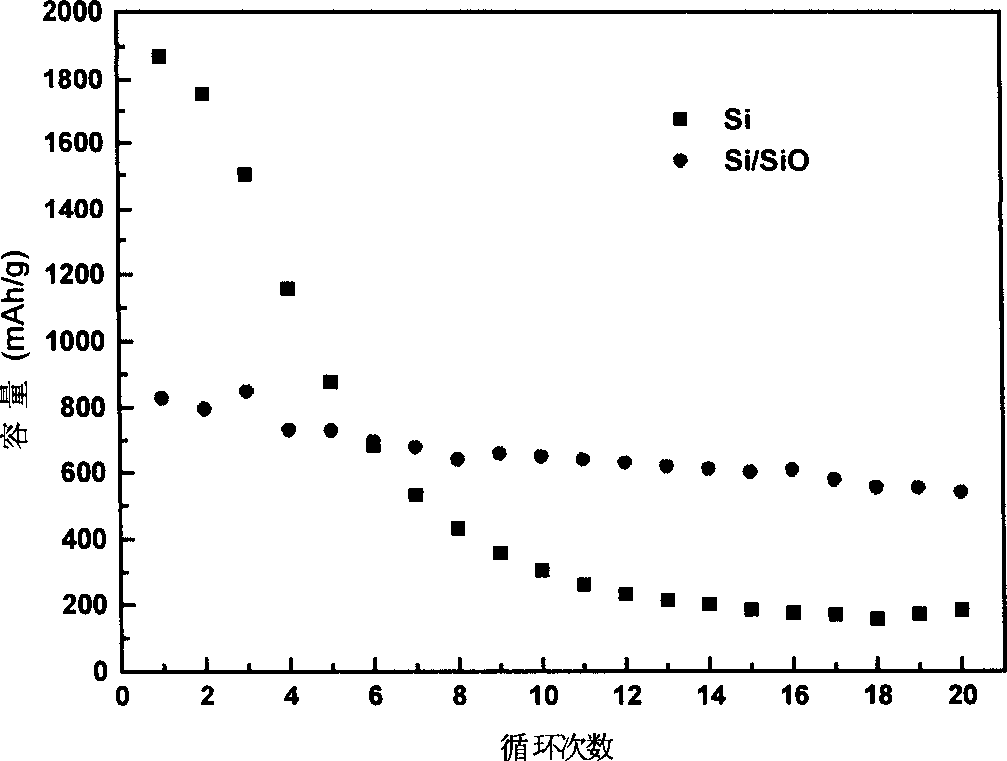

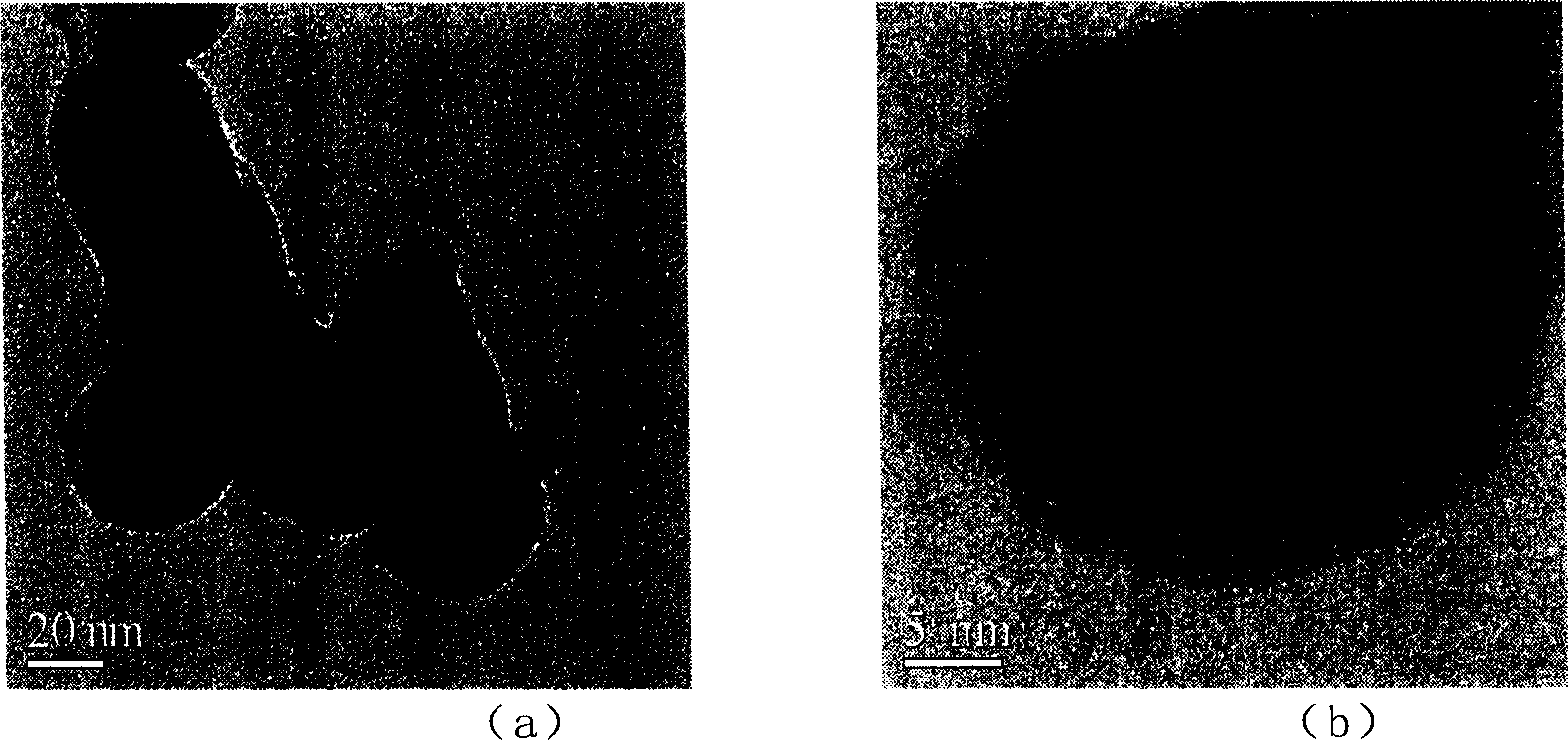

Silicon/oxidative silicon nuclear-shell structured nano-composite material, its preparation and use

A technology of nanocomposite materials and core-shell structure, applied in the field of electrochemistry, can solve problems such as unsatisfactory long-term cycle performance and loss of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the preparation method of the silicon / silicon oxide core-shell nanocomposite material of the present invention, step 1) involves the preparation process of the solution. The organic orthosilicate and the organic solvent used in this step can be industrial grade or reagent pure. From a cost point of view, industrial grade is preferred. Organic orthosilicates include ethyl orthosilicate, propyl orthosilicate, n-butyl orthosilicate and other orthosilicates, preferably ethyl orthosilicate. The amount of organoorthosilicate is 0.8ml-8ml, preferably 1.6-4ml, per gram of nano-silicon in step (2). The organic solvent can be alcohols such as ethanol, propanol, or other volatile organic solvents; as the organic solvent of the organic orthosilicate, the volume ratio of the organic orthosilicate to the organic orthosilicate is 10:1-1: 1, preferably 5:1-1:1, more preferably 2:1; the volume ratio of deionized water and organic orthosilicate is 5:1-1:1, preferably 3:1-1:1, more p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com