Method for preparing lithium ion battery negative electrode material from photovoltaic industry wastes

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to carry out large-scale industrial production, the limitation of the wide application of silicon negative electrodes, and the complex production process. The effect of cycle performance and equipment requirements is not high, and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] 2) Preparation of lithium ion battery negative electrode material:

[0042] 2.1), add the silicon powder prepared in step 1) and the dispersant (the mass ratio of the two is 4 to 1) into the solvent together, and disperse for 8-10 hours, so that the silicon powder forms uniform and dispersed nano-silicon particles; Agglomeration; the dispersant is polyhydroxy ionic liquid, alkyl ionic liquid or imidazole ionic liquid, the concentration of ionic liquid (dispersant) is 2-5mol / L; the dispersion method is ultrasonic and stirring;

[0043] 2.2), the initiator ammonium persulfate is added to the solution of step 2.1) and ultrasonicated for 30 minutes, so that the initiator is evenly dispersed on the surface of the silicon particles; the mass ratio of the ammonium persulfate to the monomer in 2.4) is 1 to 2.5;

[0044] 2.3), adding concentrated hydrochloric acid, acidifying the solution, adjusting the pH of the solution to 1-3;

[0045] 2.4), then add the monomer drop by drop...

Embodiment 1

[0050] In this embodiment, the concentration of the dispersion liquid is 3 mol / L, and the monomer is 400 mg.

[0051] 1. Disperse 200 mg of the above silicon powder in 200 mL of deionized water, add 10 mL of the prepared dispersion liquid polyhydroxy ionic liquid to the above liquid, and the concentration of the dispersion liquid is 3 mol / L;

[0052] 2. Stir for a few minutes, ultrasonically disperse for 30 minutes, and stir overnight;

[0053] 3. Weigh the initiator ammonium persulfate, dissolve it in 10mL deionized water, add it to the above liquid, and stir it ultrasonically for 30min;

[0054] 4. Use concentrated hydrochloric acid to adjust the pH of the solution obtained in step 3 to 1, add 400 mg of aniline monomer dropwise to the solution, and stir and react for 8 hours under ice bath conditions; the mass ratio of the initiator ammonium persulfate to the aniline monomer is 1 to 2.5;

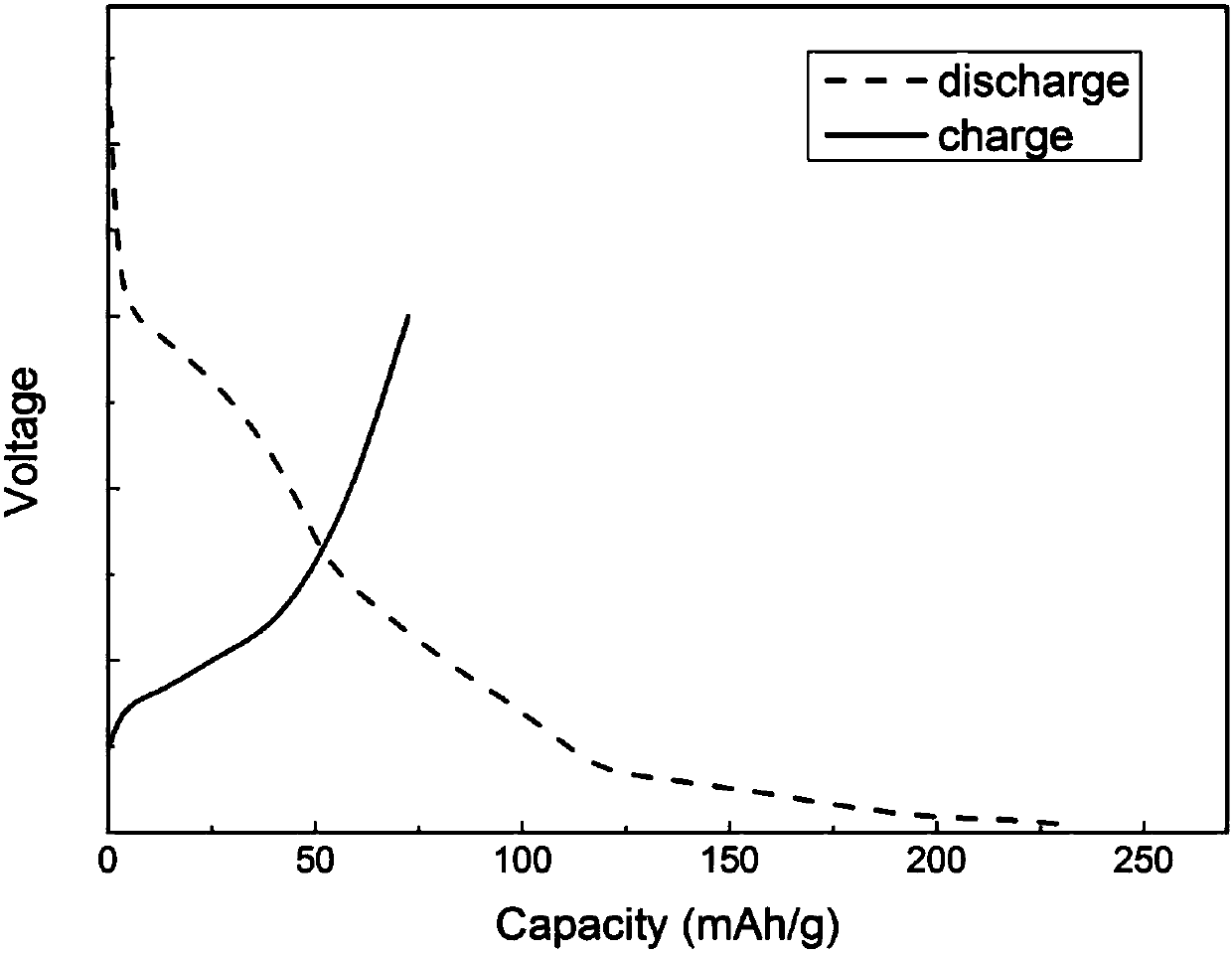

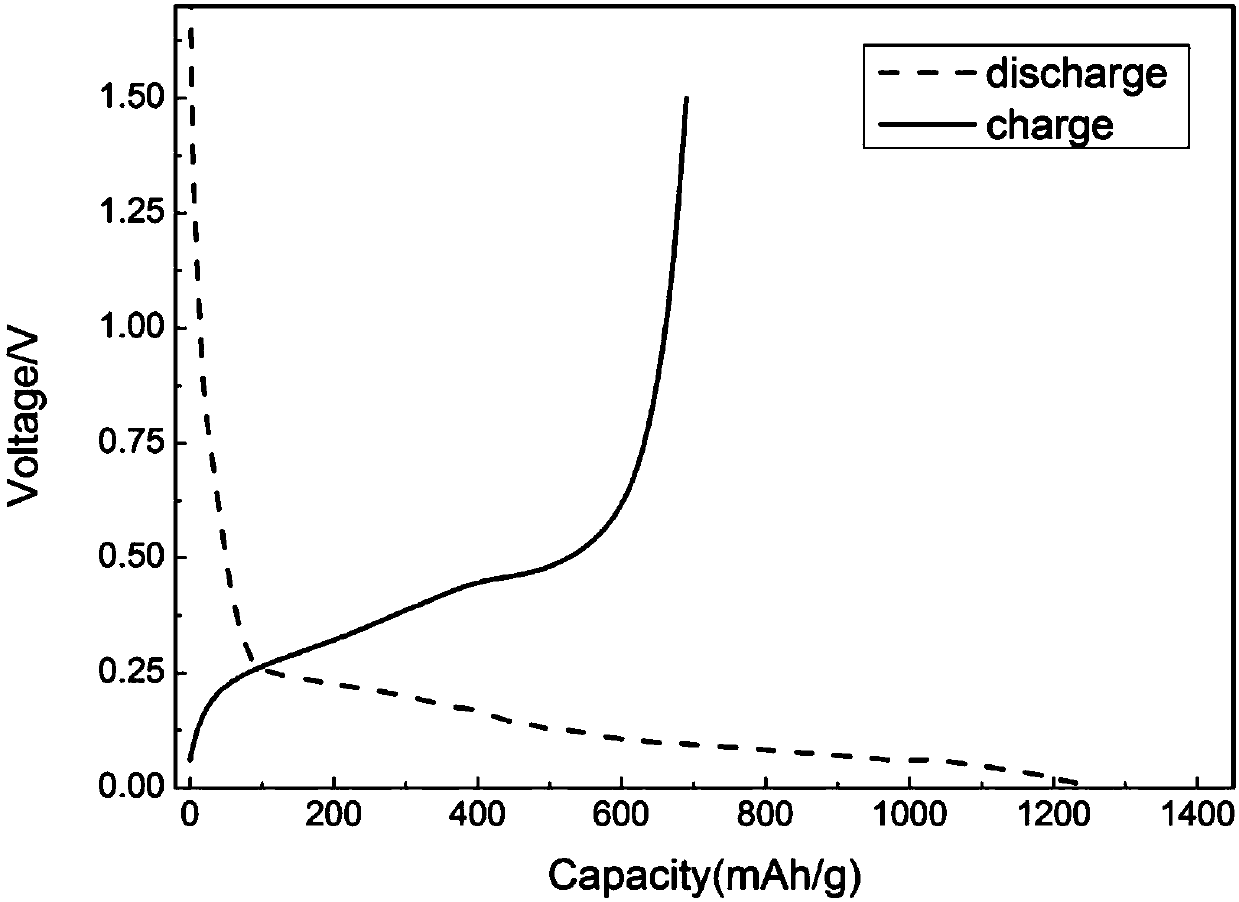

[0055] 5. Centrifuge, wash until neutral, dry, and grind to obtain the lithium-ion b...

Embodiment 2

[0058] In this embodiment, the concentration of the dispersion liquid is 4 mol / L, and the monomer is 500 mg.

[0059] 1. Disperse 200 mg of the above silicon powder in 200 mL of deionized water, add 10 mL of the prepared dispersion liquid alkyl ionic liquid to the above liquid, and the concentration of the dispersion liquid is 4 mol / L;

[0060] 2. Stir for a few minutes, ultrasonically disperse for 30 minutes, and stir overnight;

[0061] 3. Weigh the initiator ammonium persulfate, dissolve it in 10mL deionized water, add it to the above liquid, and stir it ultrasonically for 30 minutes; the mass ratio of the initiator ammonium persulfate to thiophene monomer is 1:2.5;

[0062] 4. Use concentrated hydrochloric acid to adjust the pH of the solution obtained in step 3 to 3, add 500 mg of thiophene monomer dropwise to the solution, and stir for 8 hours in an ice bath;

[0063] 5. Centrifuge, wash until neutral, dry, and grind to obtain the lithium-ion battery negative electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com