Polymer hollow nano microspheres and preparation method thereof

A nano-microsphere and polymer technology, which is applied in the fields of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc. Stability needs to be improved, practical application limitations, etc., to achieve the effects of excellent solvent resistance, low environmental dependence, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

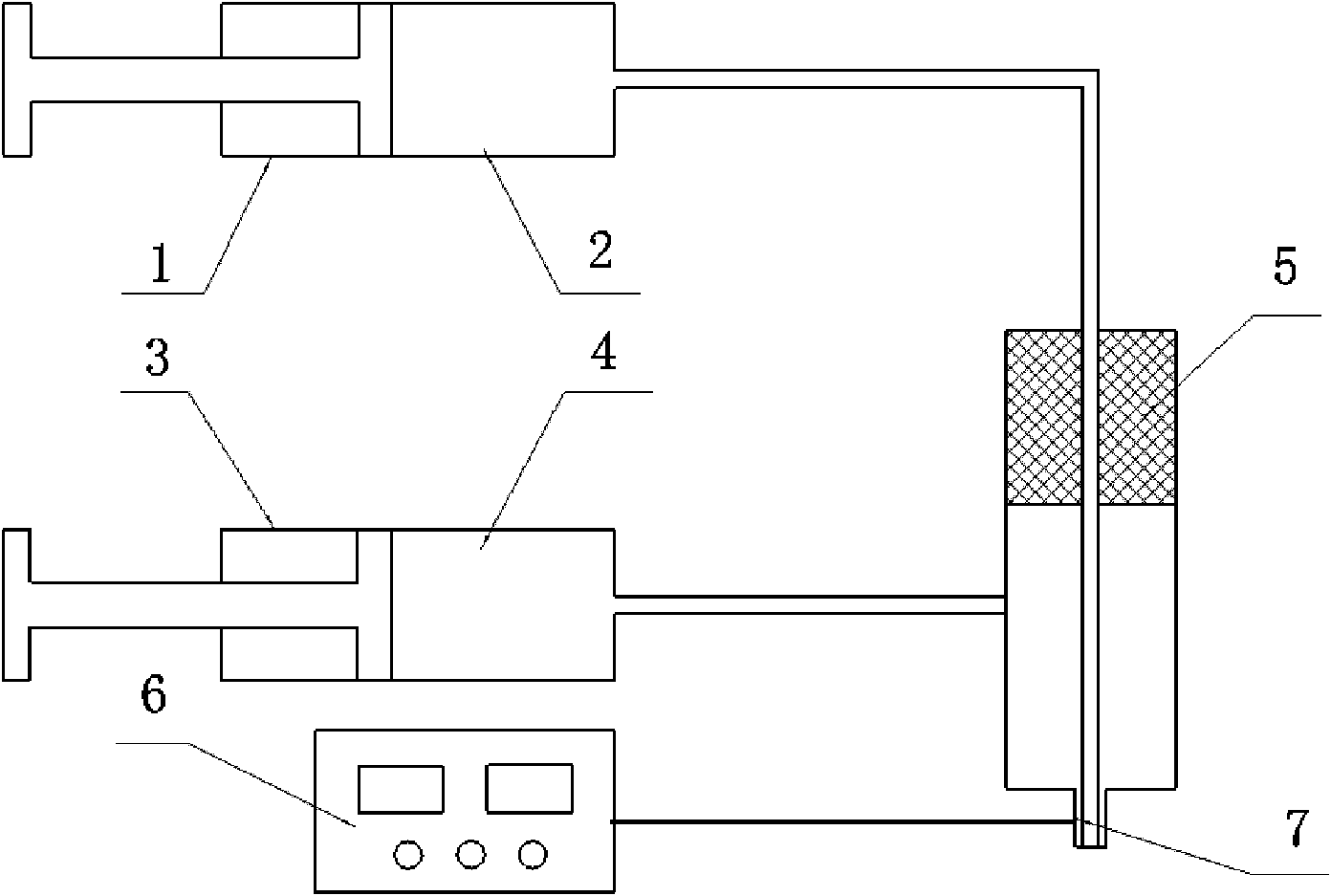

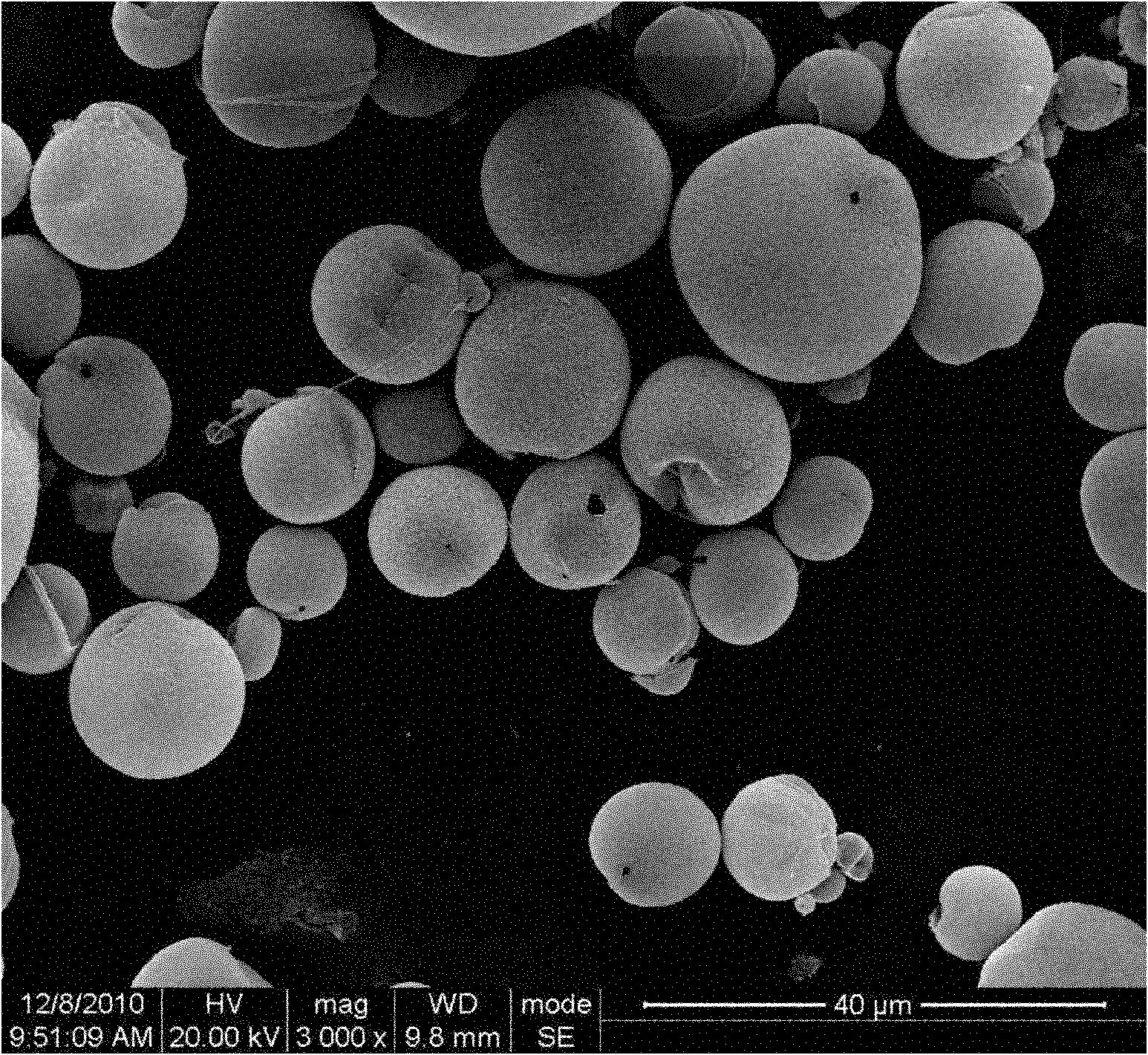

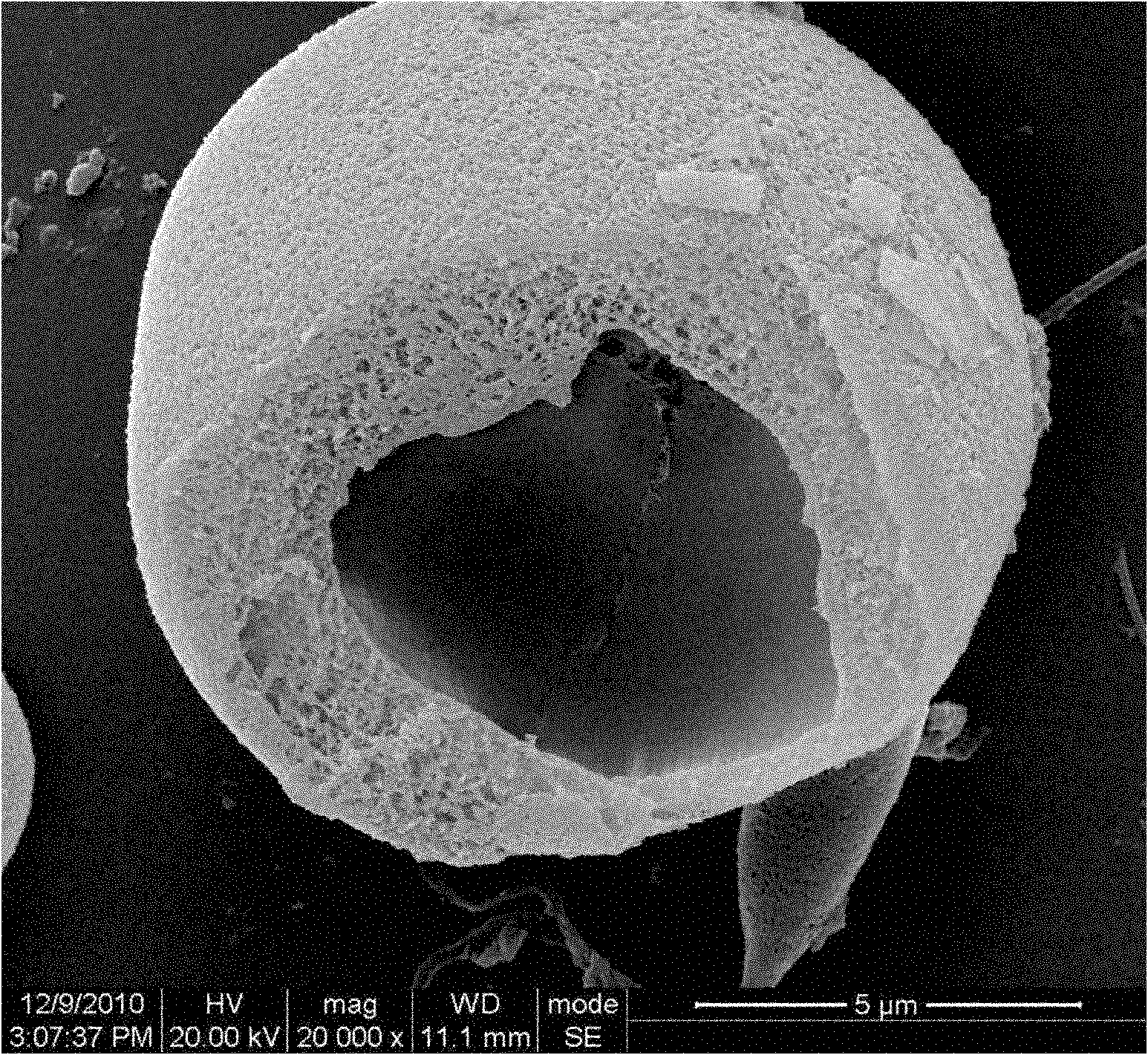

[0044] Embodiment 1: Preparation of polyethersulfone hollow nanospheres:

[0045] Add 60g of polyethersulfone and 300g of dimethyl sulfoxide into a dissolving device equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 60°C, defoam at a vacuum degree of -0.08MPa for 1 hour, and mature for 12 hours to produce an EFI shell solution. Add 20g of polyvinyl alcohol and 200g of dimethyl sulfoxide into a dissolving device equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 90°C, defoam at a vacuum degree of -0.08MPa for 1 hour, and mature for 12 hours to produce an EFI core solution. A coaxial static spraying device is adopted, wherein the inner diameter of the core needle is 0.6mm, the solution flow rate is 5ml / h, the inner diameter of the shell needle is 1.2mm, the solution flow rate is 8ml / h, the spraying voltage is adjusted to 15kv, and the spraying distance is 10cm. The bath temperature is 30°C, the electrostatic spraying...

Embodiment 2

[0046] Embodiment 2: Preparation of polyphenylene sulfide sulfone amide hollow nanospheres:

[0047]Add 100g of polyphenylene sulfide sulfoneamide, 15g of sodium chloride, and 1000g of N-methylpyrrolidone into a dissolving device equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 30°C, and defoam at a vacuum of -0.095MPa for 2 hours. Aging for 12 hours to make electrospray shell solution. Add 400g of polyethylene glycol, 600g of N-N dimethylformamide, and 400g of N,N-dimethylacetamide into a dissolving device equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 30°C, and dissolve at a vacuum degree of -0.095MPa Degassing for 2 hours and aging for 12 hours to prepare the electrospray core layer solution. A coaxial static spraying device is adopted, in which the inner diameter of the core layer needle is 0.4mm, the solution flow rate is 3ml / h, the shell layer needle inner diameter is 0.9mm, the solution flow rate is 5ml / ...

Embodiment 3

[0048] Embodiment 3: Preparation of polyphenylene sulfide sulfone amide hollow nanospheres:

[0049] Add 200g of polyphenylene sulfide sulfone amide, 15g of calcium chloride, and 900g of N,N-dimethylacetamide into a dissolution device equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 100°C, and dissolve at a vacuum degree of -0.085MPa Degassing for 2 hours and aging for 12 hours to prepare the EFI shell solution. Add 20g of chitosan and 300g of acetic acid into a dissolving device equipped with a stirrer and a thermometer, stir and swell at a temperature of 30°C until dissolved, defoam in a vacuum of -0.085MPa for 2 hours, and mature for 12 hours to make an EFI core layer solution. A coaxial static spraying device is adopted, wherein the inner diameter of the core needle is 0.4mm, the solution flow rate is 2ml / h, the inner diameter of the shell needle is 1.1mm, the solution flow rate is 9ml / h, the spraying voltage is adjusted to 25kv, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com