Method for preparing industrial ultra-fine activated calcium carbonate from carbide slag

A technology of activated calcium carbonate and carbide slag, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of increasing the added value of carbide slag, achieve the effect of improving utilization rate and value, cheap price, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

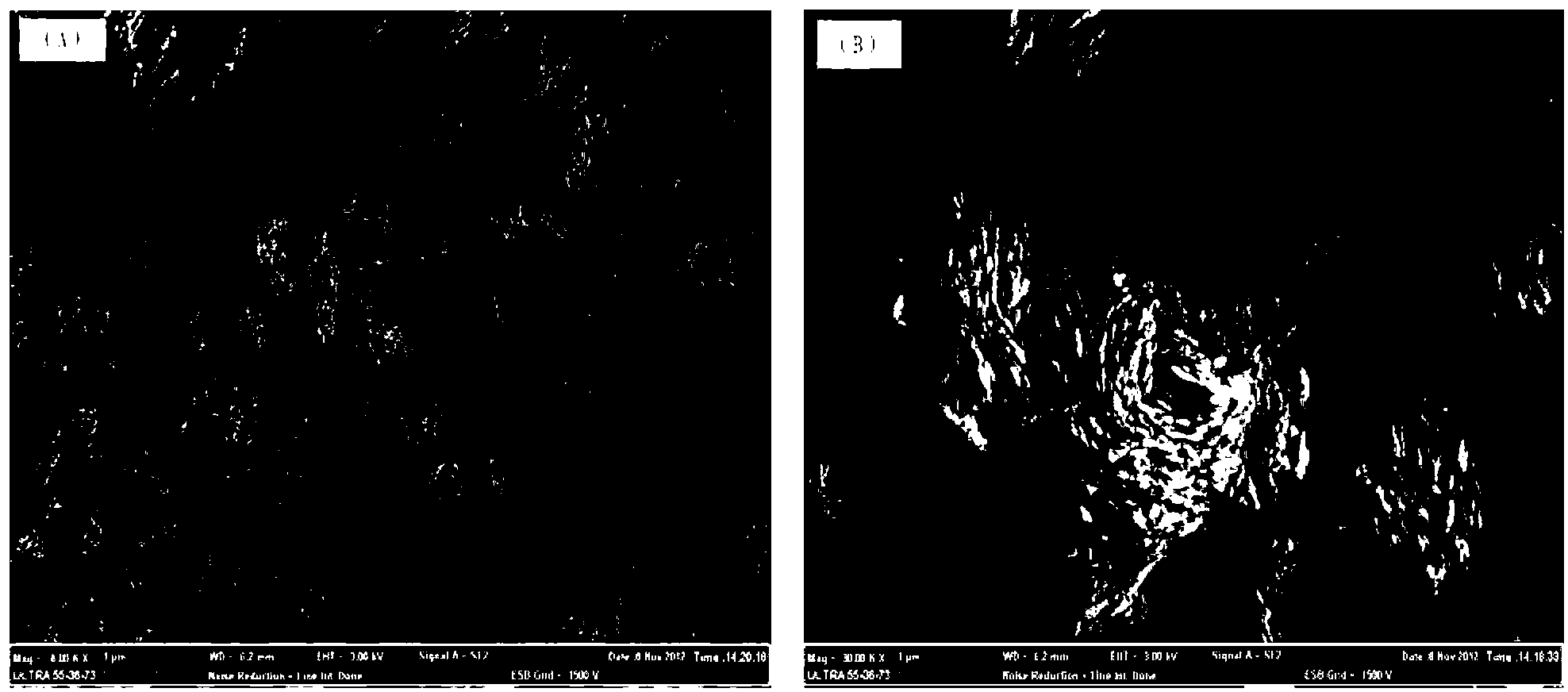

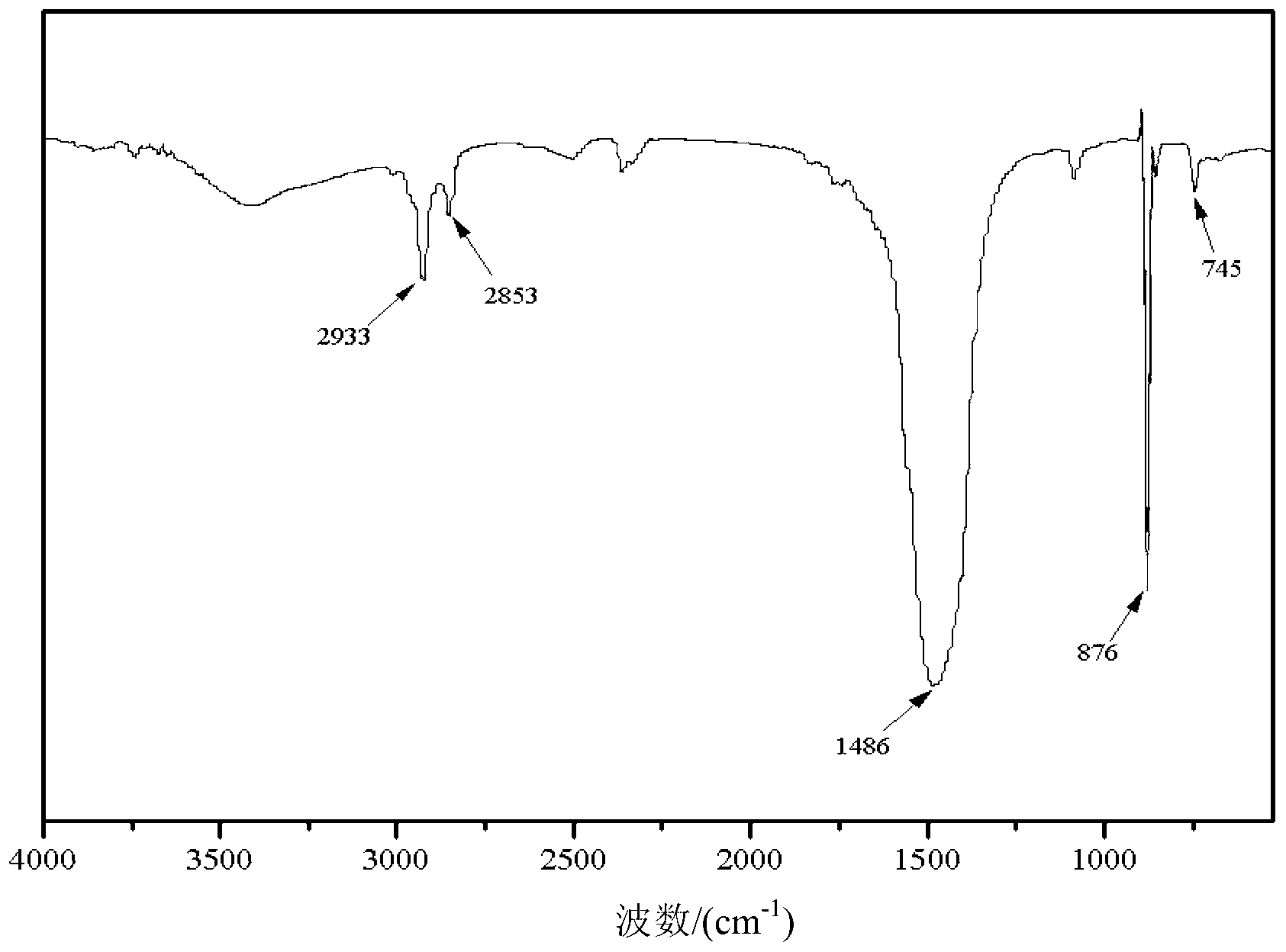

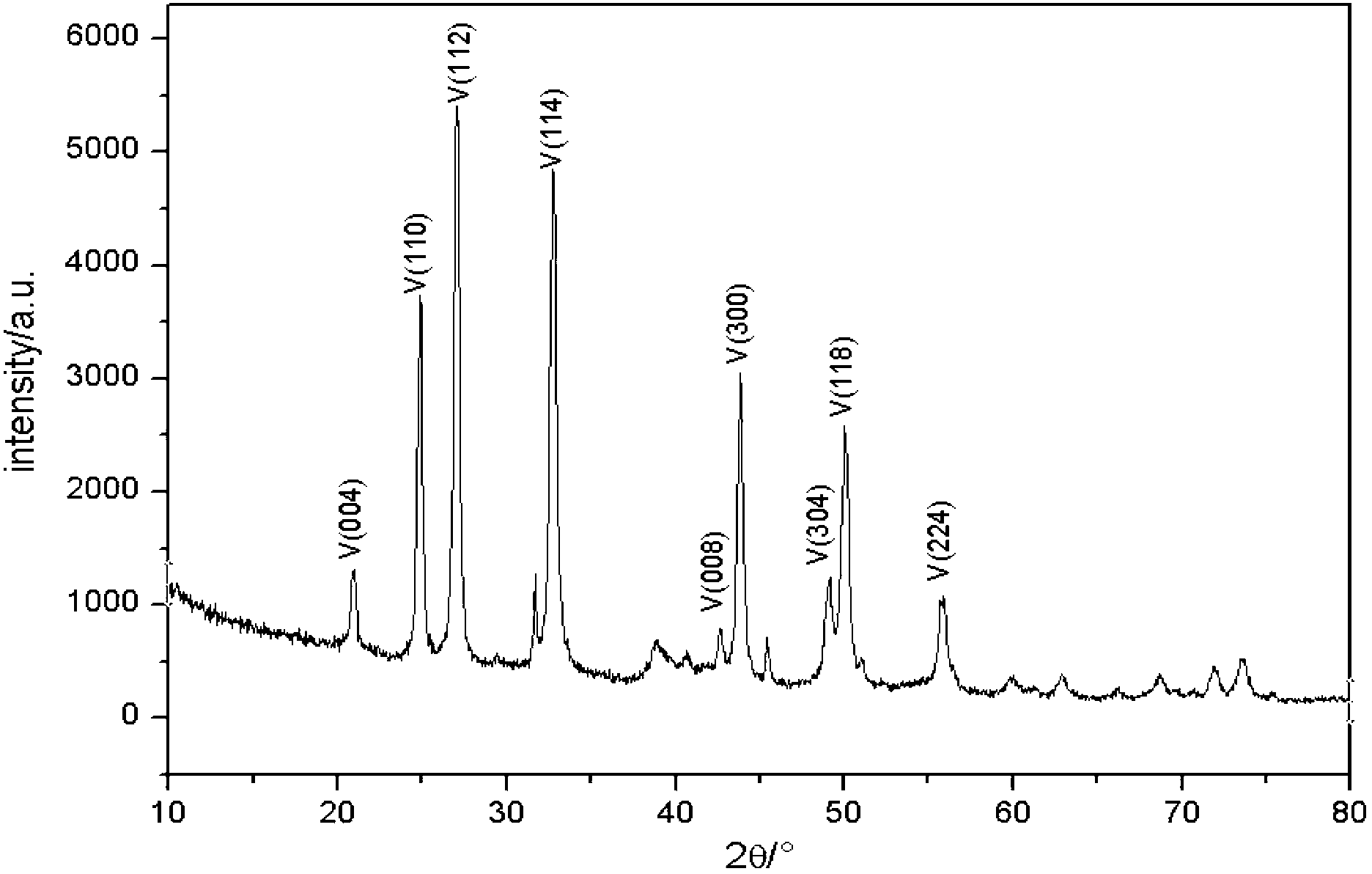

[0060] Embodiment 1: use n-butanol as co-surfactant, oleic acid as surfactant, adopt microemulsion to prepare industrial superfine active calcium carbonate from calcium carbide slag

[0061] Weigh 30g of calcium carbide slag (Liuzhou Chemical Industry Co., Ltd., with reference to the national standard GB25572-2010, the content of calcium hydroxide is 85.2% pre-measured by complexometric titration with disodium EDTA), put it into the reaction kettle, and add 10mL Wet with water, and slowly add 130ml of saturated ammonium chloride solution (100ml of water contains 40g of ammonium chloride) dropwise under the condition of a hot water bath at 30°C, and control the pH value of the solution at about 7.1-8. After stirring for 80 minutes, the reaction was completed, and the insoluble impurities were removed by filtration to obtain 230ml of calcium chloride solution, in which the concentration of calcium ions was 1.375mol / L (measured by complexometric titration with calcium indicator ED...

Embodiment 2

[0063] Embodiment 2: use the oil phase and water phase that embodiment 1 obtains, adopt microemulsion to obtain industrial superfine active calcium carbonate from calcium carbide slag

[0064] Weigh 30g of calcium carbide slag (Liuzhou Chemical Industry Co., Ltd., with reference to the national standard GB25572-2010, the content of calcium hydroxide is 85.2% pre-measured by complexometric titration with disodium EDTA), put it into the reaction kettle, and add 10mL Wet with water, and slowly add 130ml of saturated ammonium chloride solution (100ml of water contains 40g of ammonium chloride) dropwise under the condition of a hot water bath at 40°C, and control the pH value of the solution at about 7.1-8. After stirring for 80 minutes, the reaction was completed, and the insoluble impurities were removed by filtration to obtain 205ml of calcium chloride solution, wherein the concentration of calcium ions was 1.588mol / L (measured by complexometric titration with calcium indicator E...

Embodiment 3

[0066] Embodiment 3: use the oil phase and water phase that embodiment 2 obtains, adopt microemulsion to obtain industrial superfine active calcium carbonate from calcium carbide slag

[0067]Weigh 30g of calcium carbide slag (Liuzhou Chemical Industry Co., Ltd., with reference to the national standard GB25572-2010, the content of calcium hydroxide is 85.2% pre-measured by complexometric titration with disodium EDTA), put it into the reaction kettle, and add 10mL Wet with water, slowly add 130ml of saturated ammonium chloride solution (100ml of water contains 40g of ammonium chloride) dropwise in a hot water bath at 60°C, and control the pH value of the solution at about 6-8. After stirring for 80 minutes, the reaction was completed, and the insoluble impurities were removed by filtration to obtain 212ml of calcium chloride solution, wherein the concentration of calcium ions was 1.457mol / L (measured by complexometric titration with calcium indicator EDTA), and the leaching rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com