Metal gas mixing ion injector

An ion implanter and gas mixing technology, which is applied in ion implantation plating, metal material coating process, electrical components, etc., can solve the problems of limited function and use range of ion implanter, poor effect, etc. Low cost, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

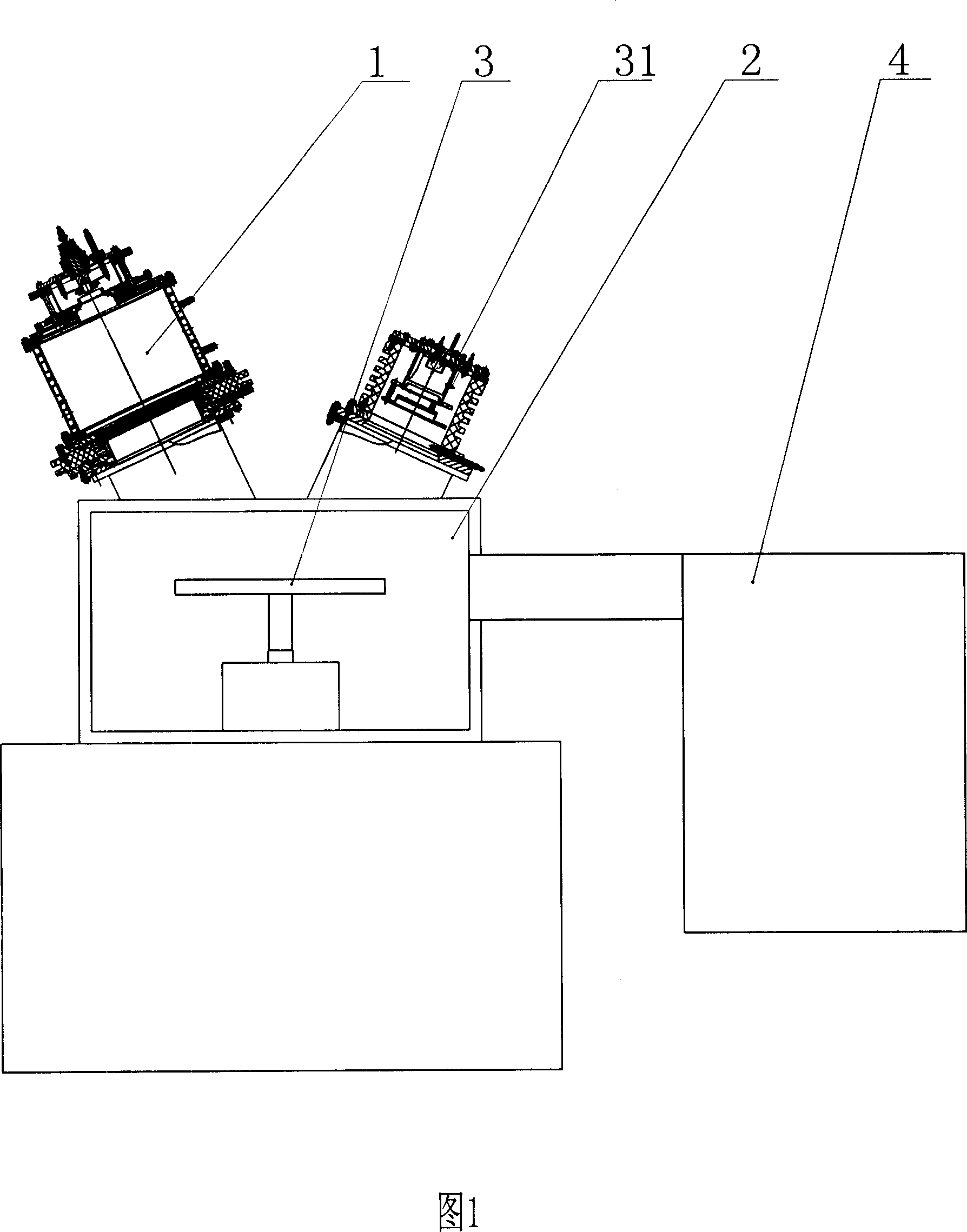

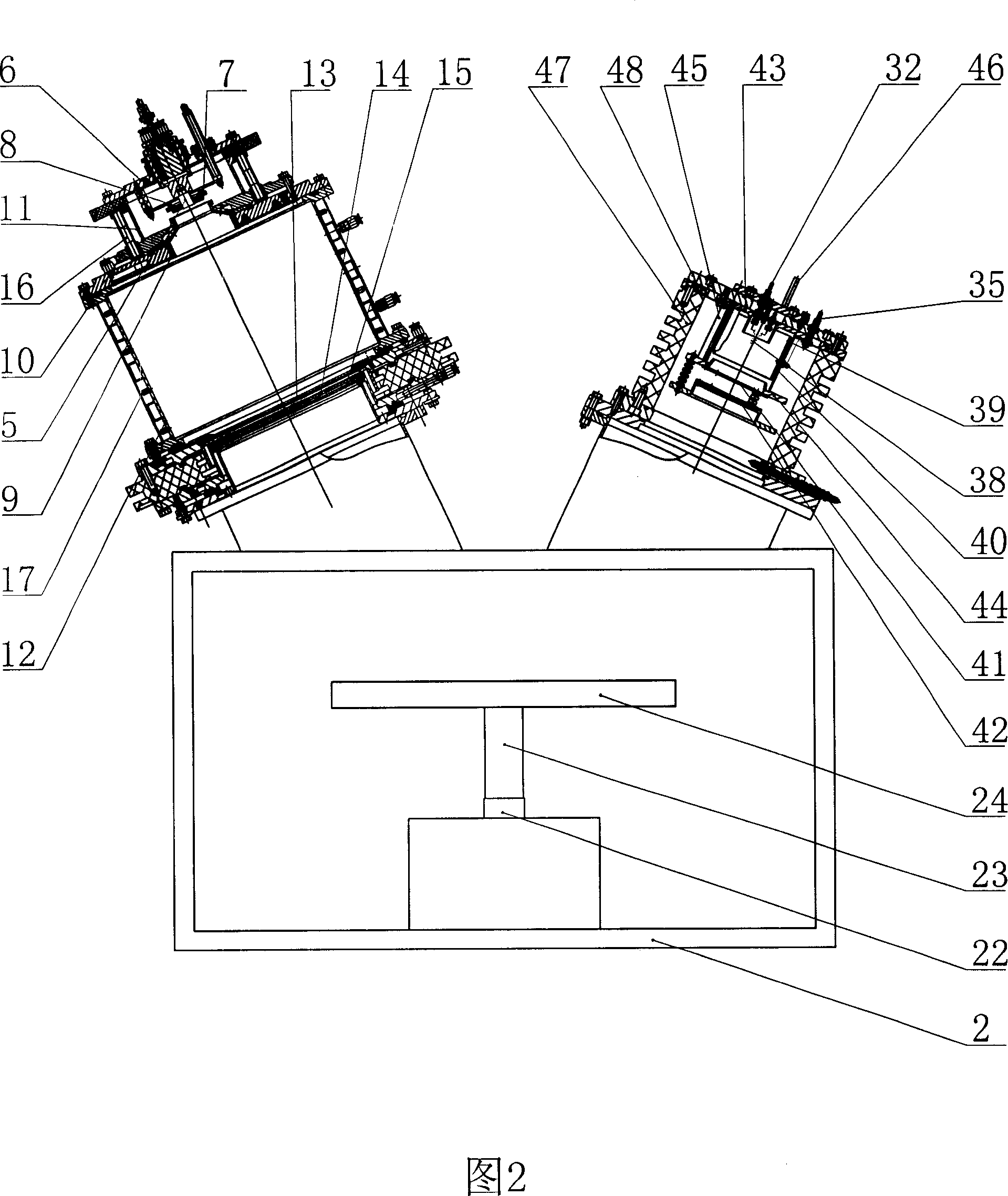

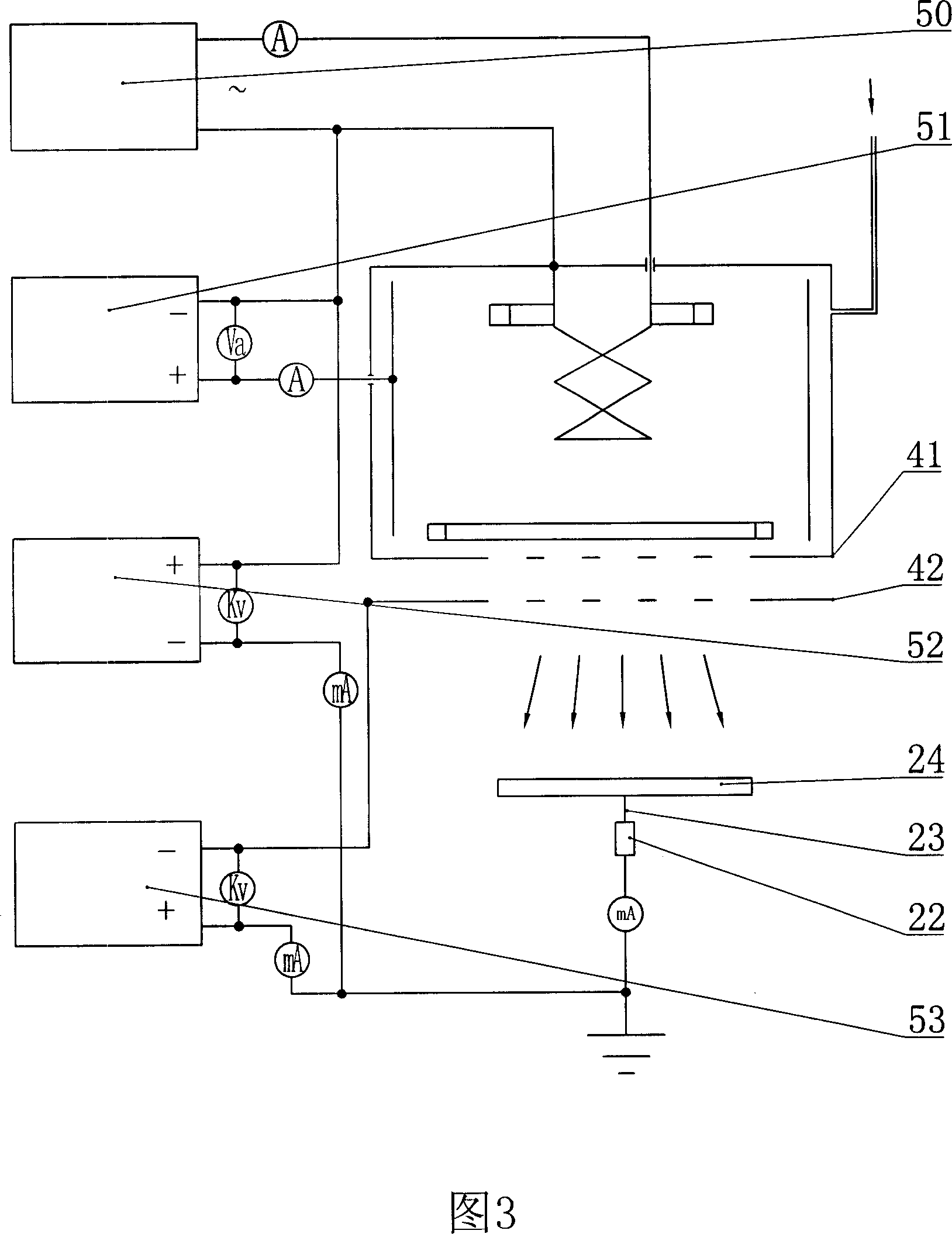

[0018] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention includes a metal ion source 1, a gas ion source 31, a metal ion source power supply system, a gas ion source power supply system, a vacuum chamber 2, a workpiece target platform 3, a motor 22. Vacuum pumping system 4, cooling system, nitrogen source 25, mass flow valve 26, control panel, and gas supply system.

[0019] The metal ion source 1 and the gas ion source 31 are arranged on the top of the vacuum chamber 2 and communicate with the vacuum chamber 2, and the metal ion source 1 and the gas ion source 31 form an angle of 24° with the vertical direction respectively. .

[0020] The gas ion source 31 includes a cathode terminal 32, an anode terminal 35, a filament 38, a discharge chamber 39, a discharge chamber 40, a grid 41, a second grid 42, an anode shoe 43, a cathode shoe 44, a magnetic rod 45, Air inlet 46, insulation cylinder 47, upper cover 48, described upper cover 48 is arranged on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com