Separation device, stripping device and recovery method of battery positive electrode

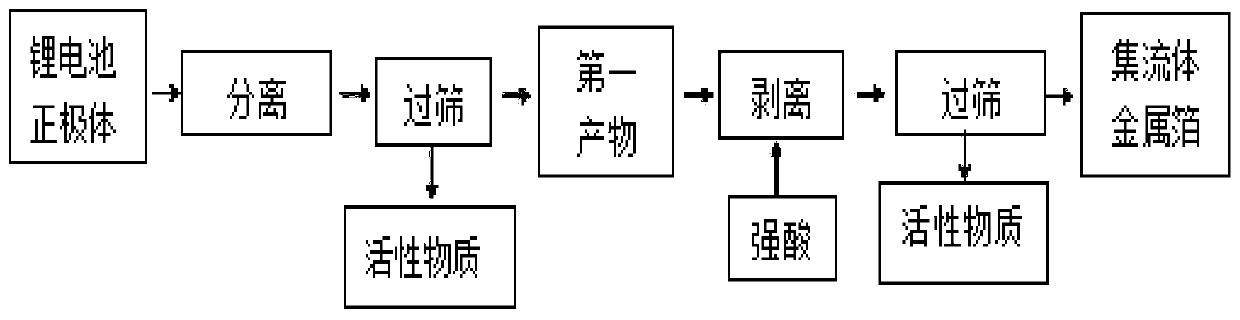

A technology of stripping device and separation device, which is applied in the field of chemical material recycling, can solve the problems of difficult and complex handling and many fluids, and achieve the effect of short process flow, simple equipment and high stripping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1 adopts the recycling method of the present invention to recycle the positive electrode of the battery

[0081] Raw material: Lithium battery cathode sheet material with aluminum foil as current collector. Analysis and detection of its composition: Co content 4.83%, Ni content 15.19%, Mn content 8.46%, Li content 3.82%, Al content 17.13%.

[0082] Recycling method:

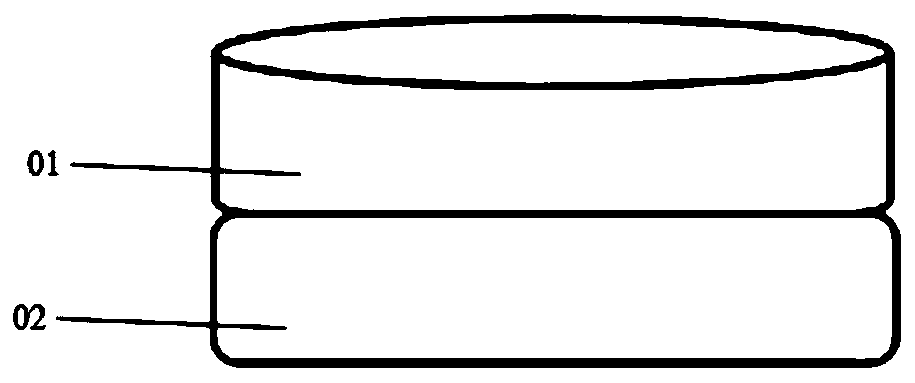

[0083] Separation: Put the positive electrode of the lithium battery in the screening device 01 of the 40-mesh separation device, bake it at 220°C for 2 hours, vibrate and screen the material tray once every hour, and the melted fluid falls through the sieve holes and falls on the screening device In the receiving device 02 that is clamped with 01, what remains on the screening device 01 is the first product.

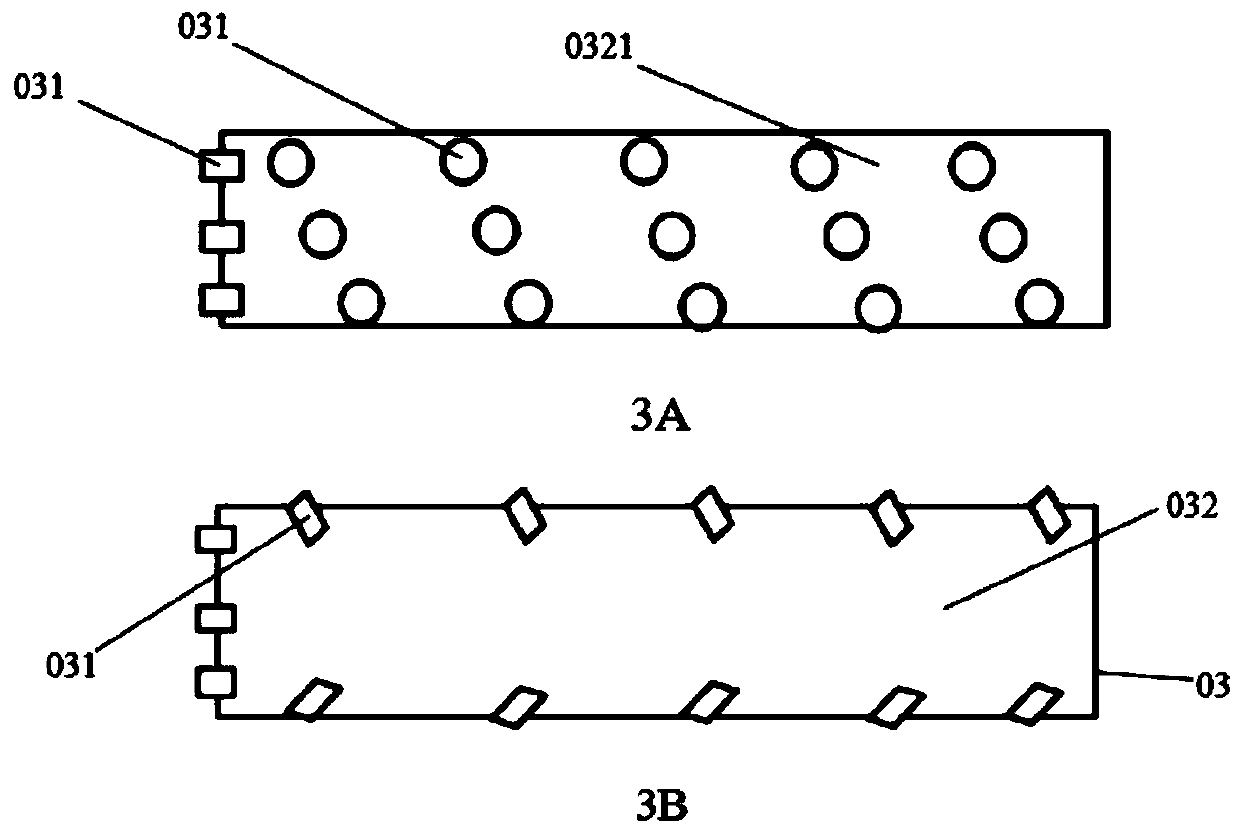

[0084] Peeling: The peeling device 03 is a rectangular trough-shaped device with a ratio of length, width and height of 7:1:1. The distribution density of the spray device 031 in the rea...

Embodiment 2

[0086] Embodiment 2 adopts the recycling method of the present invention to recycle the positive electrode of the battery

[0087] Raw material: Lithium battery cathode sheet material with aluminum foil as current collector. Analysis and detection of its composition: Co content 4.83%, Ni content 15.19%, Mn content 8.46%, Li content 3.82%, Al content 17.13%.

[0088] Recycling method:

[0089] Separation: Put the positive electrode of the lithium battery in the screening device 01 of the 30-mesh separation device, bake it at 250°C for 2 hours, vibrate and screen the material tray once every hour, and the melted fluid falls through the sieve holes and falls on the screening device In the receiving device 02 that is clamped with 01, what remains on the screening device 01 is the first product.

[0090] Peeling: The peeling device 03 is a rectangular trough-shaped device with a ratio of length, width and height of 7:1:1. The distribution density of the spray device 031 in the rea...

Embodiment 3

[0092] Embodiment 3 adopts the recovery method of the present invention to recycle the positive electrode of the battery

[0093] Raw material: Lithium battery cathode sheet material with aluminum foil as current collector. Analysis and detection of its composition: Co content 4.83%, Ni content 15.19%, Mn content 8.46%, Li content 3.82%, Al content 17.13%.

[0094] Recycling method:

[0095] Separation: Put the positive electrode of the lithium battery in the screening device 01 of the 10-mesh separation device, bake it at 200°C for 4 hours, vibrate and screen the tray once every hour, and the melted fluid falls through the sieve holes and falls on the screening device In the receiving device 02 that is clamped with 01, what remains on the screening device 01 is the first product.

[0096]Peeling: The peeling device 03 is a cylindrical trough device with a ratio of length and diameter of 7:1, the distribution density of the spray device 031 in the reaction tank 032 is 84 piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com