A separation device, a stripping device, and a method for recycling positive electrodes of batteries

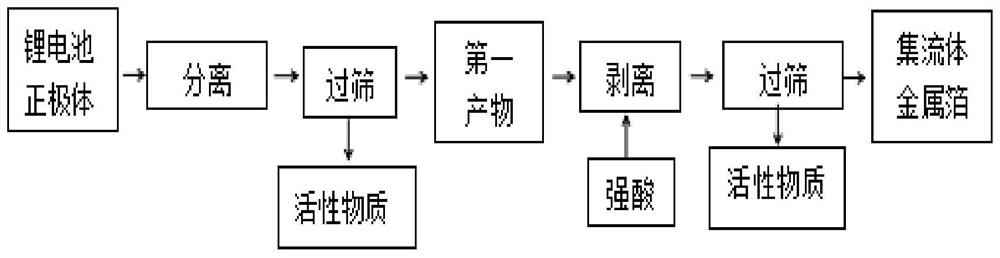

A recycling method and battery positive electrode technology, which is applied in the field of chemical material recycling, can solve the problems of difficult and complicated handling and many fluids, and achieve the effects of short process flow, convenient feeding and retrieving, good penetration and cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Recovering method of the present embodiment of the invention a positive battery recycling

[0081] Starting material: aluminum foil as a positive electrode lithium electrode current collector sheet material, having a composition analysis and detection: Co content of 4.83%, Ni content of 15.19%, Mn content of 8.46%, Li content of 3.82%, Al content of 17.13%.

[0082] Recovery methods:

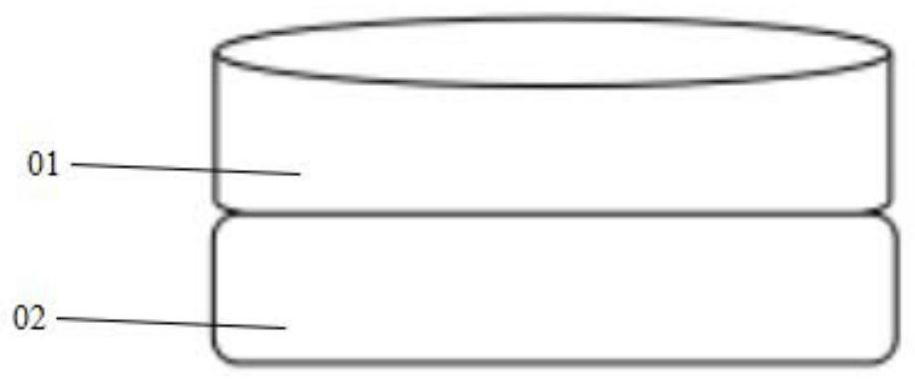

[0083] Separation: The lithium battery cathode screening apparatus 0140 placed object separation device, baked at a temperature of 220 ℃ 2 hours every hour a vibratory screening tray, melted and fluid falls through the sieve screening device splice device 01 of the snap 02, 01 remaining on the screening device is a first product.

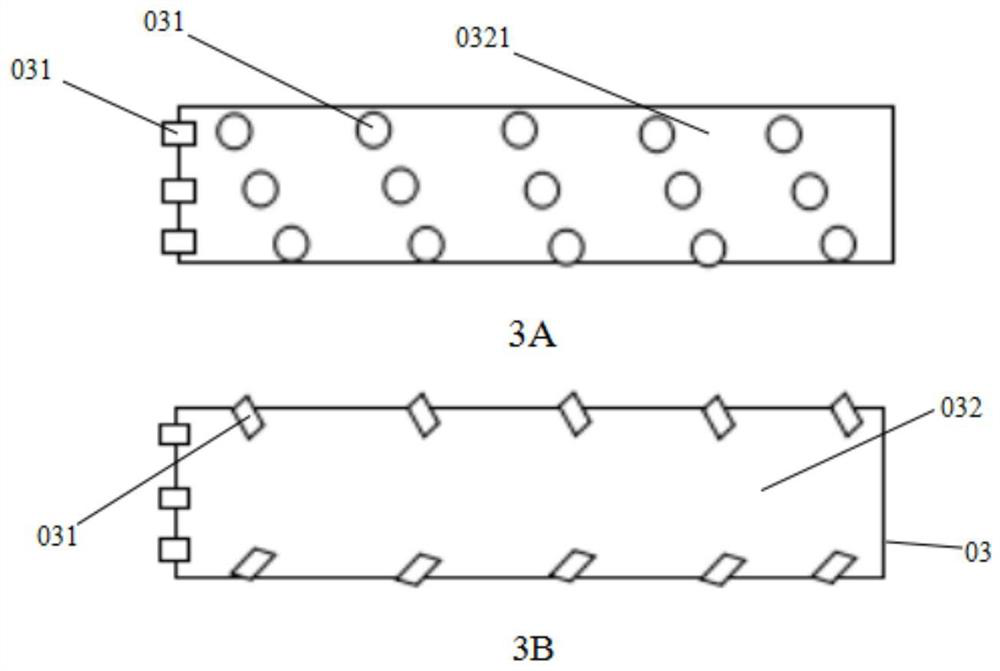

[0084] Release: release means 03 is a length and breadth ratio of 7: 1: 1 means a rectangular groove, the ejection means 031 in the distribution density of the reaction vessel 032 is 70 / m, ejection means 031 of injection port an inner diameter of 1.5mm, the eject...

Embodiment 2

[0086] Using the recovery method of the present invention Example 2 The positive electrode of the battery is recovered

[0087] Starting material: aluminum foil as a positive electrode lithium electrode current collector sheet material, having a composition analysis and detection: Co content of 4.83%, Ni content of 15.19%, Mn content of 8.46%, Li content of 3.82%, Al content of 17.13%.

[0088] Recovery methods:

[0089] Separation: The lithium battery cathode unit 01 placed on a 30 mesh sieve separation device, baked at a temperature of 250 ℃ 2 hours every hour a vibratory screening tray, melted and fluid falls through the sieve screening device splice device 01 of the snap 02, 01 remaining on the screening device is a first product.

[0090] Release: release means 03 is a length and breadth ratio of 7: 1: 1 means a rectangular groove, the ejection means 031 in the distribution density of the reaction vessel 032 was 90 / m, ejection means 031 of injection port an inner diameter o...

Embodiment 3

[0092] 3 recovery method of the present embodiment of the invention the positive electrode cell recycling

[0093] Starting material: aluminum foil as a positive electrode lithium electrode current collector sheet material, having a composition analysis and detection: Co content of 4.83%, Ni content of 15.19%, Mn content of 8.46%, Li content of 3.82%, Al content of 17.13%.

[0094] Recovery methods:

[0095] Separation: The lithium battery cathode screening device 0110 placed object separation device, baked at a temperature of 200 ℃ 4 h every hour a vibratory screening tray, melted and fluid falls through the sieve screening device splice device 01 of the snap 02, 01 remaining on the screening device is a first product.

[0096]Release: release means 03 is a length and diameter ratio of 7: 1 cylindrical groove means, the density distribution apparatus 031 in the reaction vessel 032 of the injector 84 is / m², inner diameter of the injection port of the injection means 031 is 2mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com