Metal ion implantation machine

A technology of metal ion implantation and metal ion source, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high beam extraction voltage, long injection time, small injection area, etc. Effect of high peeling rate, short injection time, and low injection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

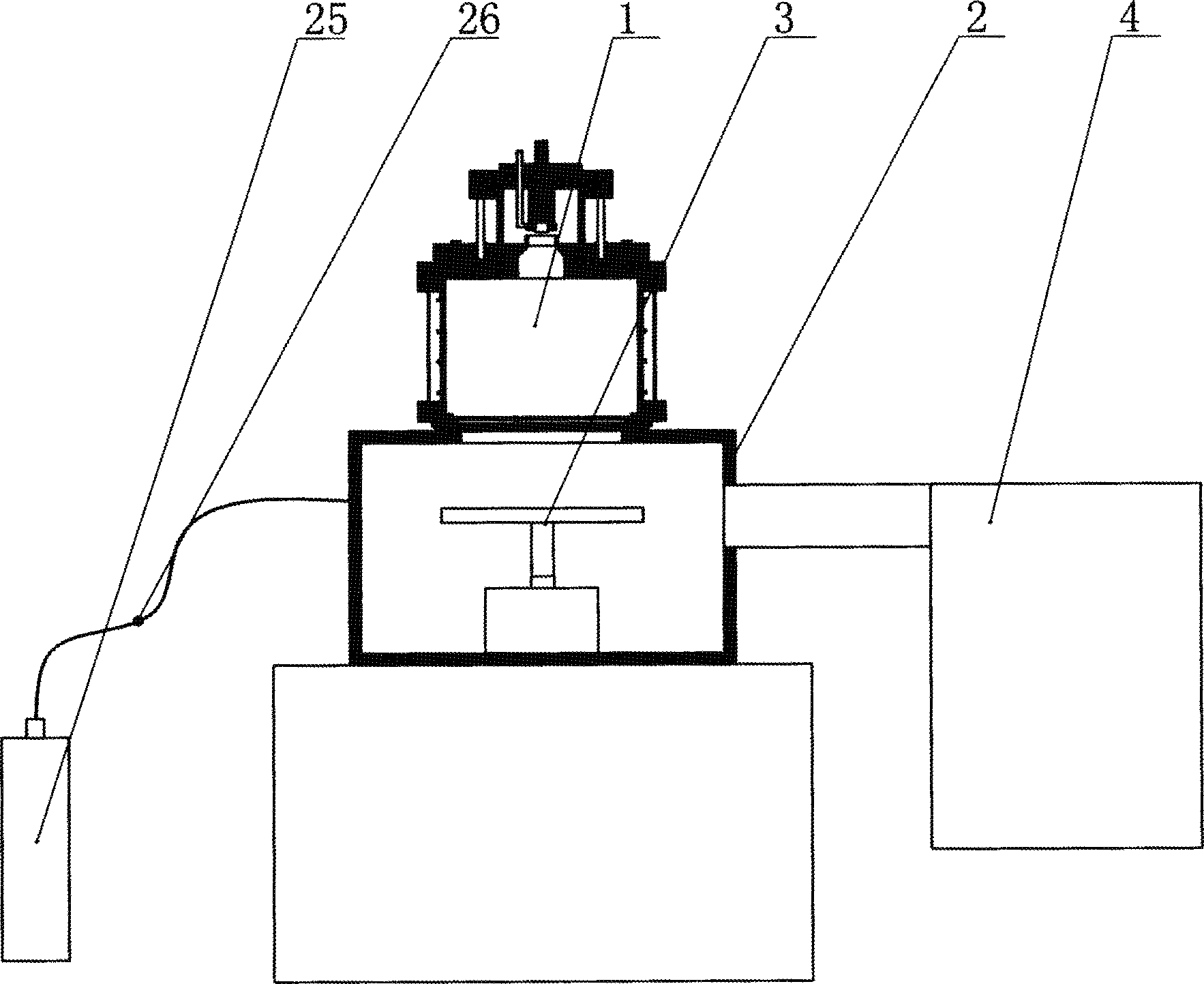

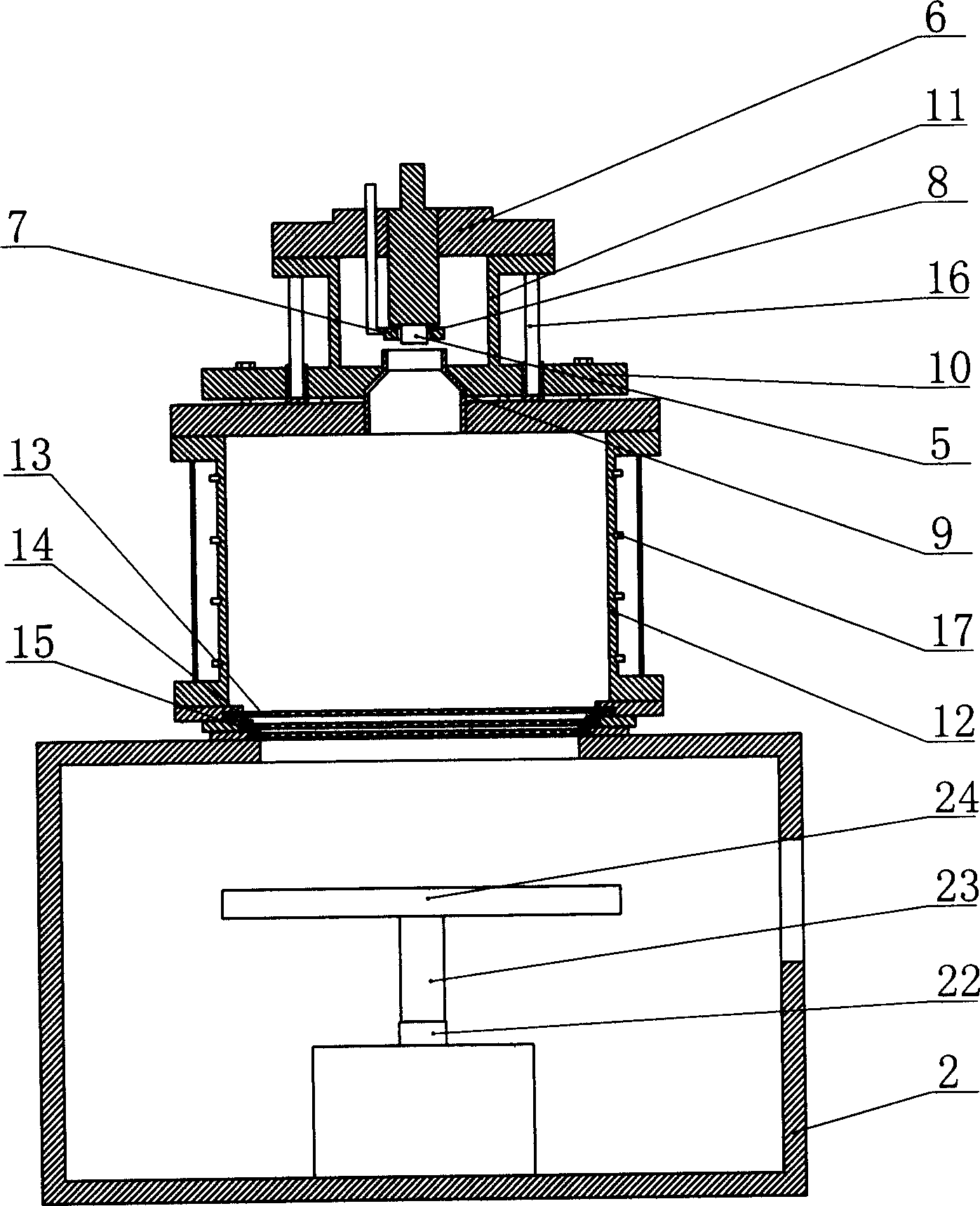

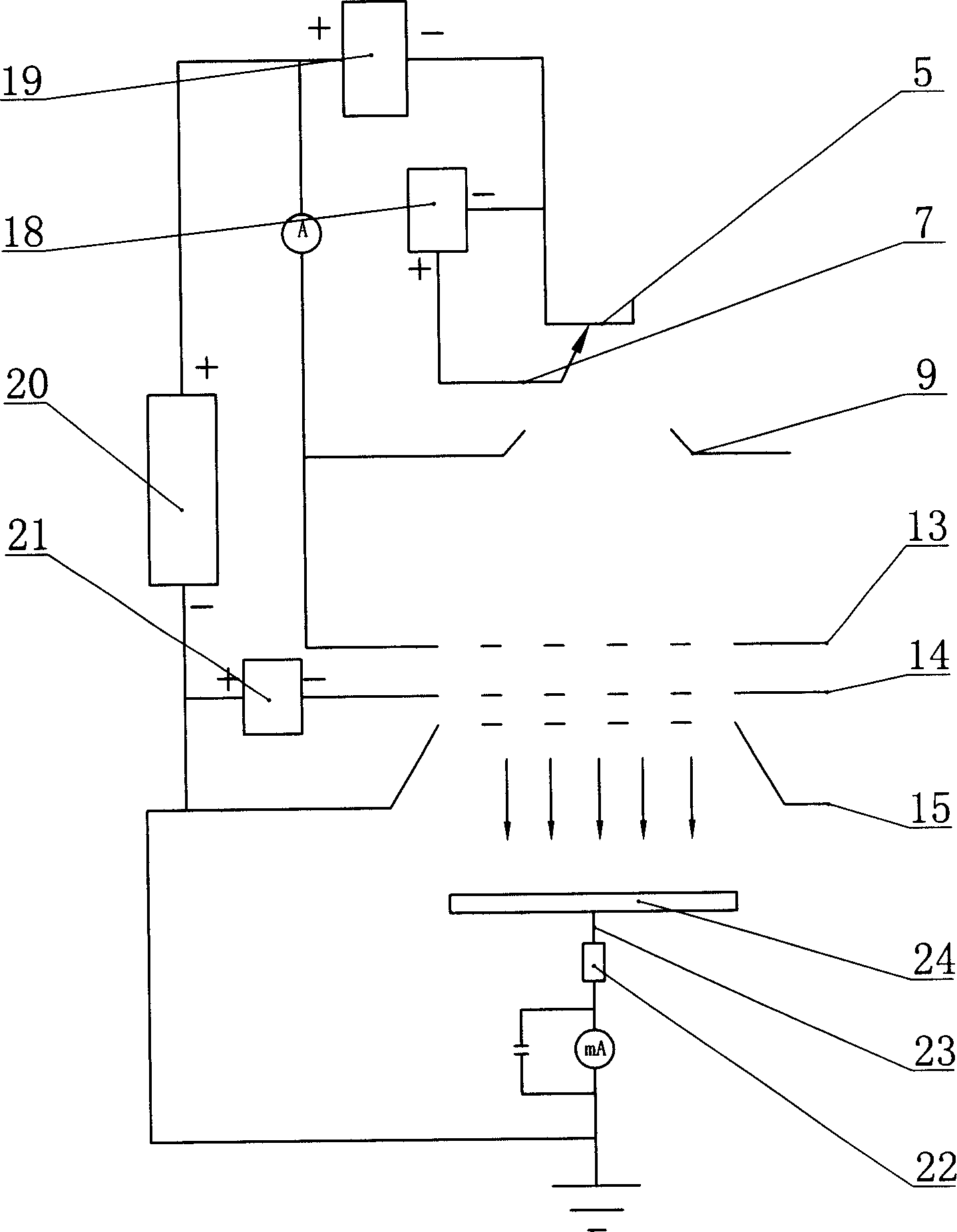

[0015] like figure 1 , figure 2 As shown, the present invention includes a metal ion source 1, an ion source power supply system, a vacuum chamber 2, a workpiece target stage 3, a motor 22, a vacuum system 4, a cooling system, a nitrogen source 25, a mass flow valve 26 and a control panel.

[0016] The metal ion source 1 is arranged on the upper part of the vacuum chamber 2 and communicated with the vacuum chamber 2 . The metal ion source includes a cathode 5, a cathode support 6, a trigger electrode 7, an insulating cathode casing 8, an anode 9, an anode support 10, a discharge chamber 11, a plasma chamber 12, a first grid 13, a second grid 14 and a third grid. Grid 15, the trigger electrode 7 is separated by the insulating cathode sleeve 8 and placed on the outer periphery of the cathode 5, the upper end of the discharge chamber 11 is connected to the cathode support 6, and the lower end is connected to the anode support 10, The outer periphery of the discharge chamber 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com