Layered nanoparticles, stripping method and application thereof

A layered nanometer and nanoparticle technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unsuitable industrial mass production and high cost of peeling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

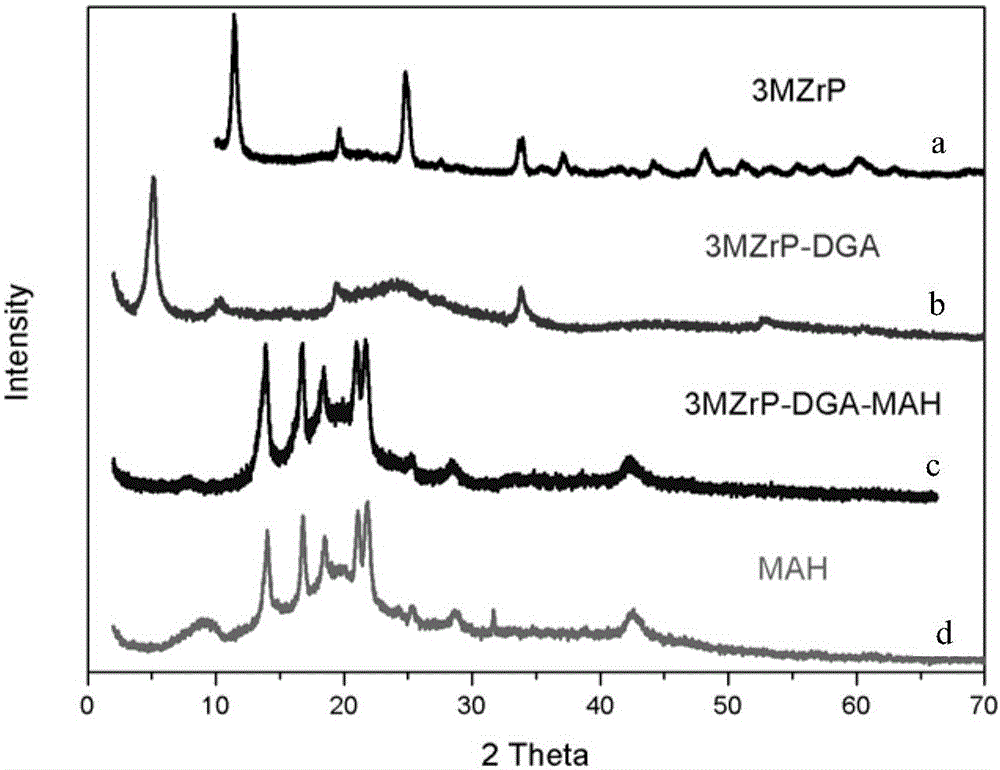

Embodiment 1

[0062] The stripping method of the layered α-zirconium phosphate of the present embodiment comprises the following steps:

[0063] (1') preparing layered α-zirconium phosphate;

[0064] (1'a) Weigh 4.0g ZrOCl 2 ·8H 2 O, and the preparation 40ml concentration is the phosphoric acid solution of 3mol / L; ZrOCl 2 ·8H 2 O and phosphoric acid were poured into the Teflon reactor together and stirred for 3min to obtain a reaction mixture;

[0065] (1'b) Put the Teflon reaction kettle into the oven to react at 200°C for 24h. After cooling down to room temperature naturally, wash it with deionized water for 3 times, then put the prepared precipitate into the oven and heat it at 75°C. Dry for 24 hours, and then grind the dried product to obtain layered α-zirconium phosphate powder.

[0066] (1) Amination treatment; Weigh 1.0g α-ZrP, pour it into 100g diglycolamine, and then mix it ultrasonically for 8 hours to obtain a mixed solution; use absolute ethanol to prepare the organic amine s...

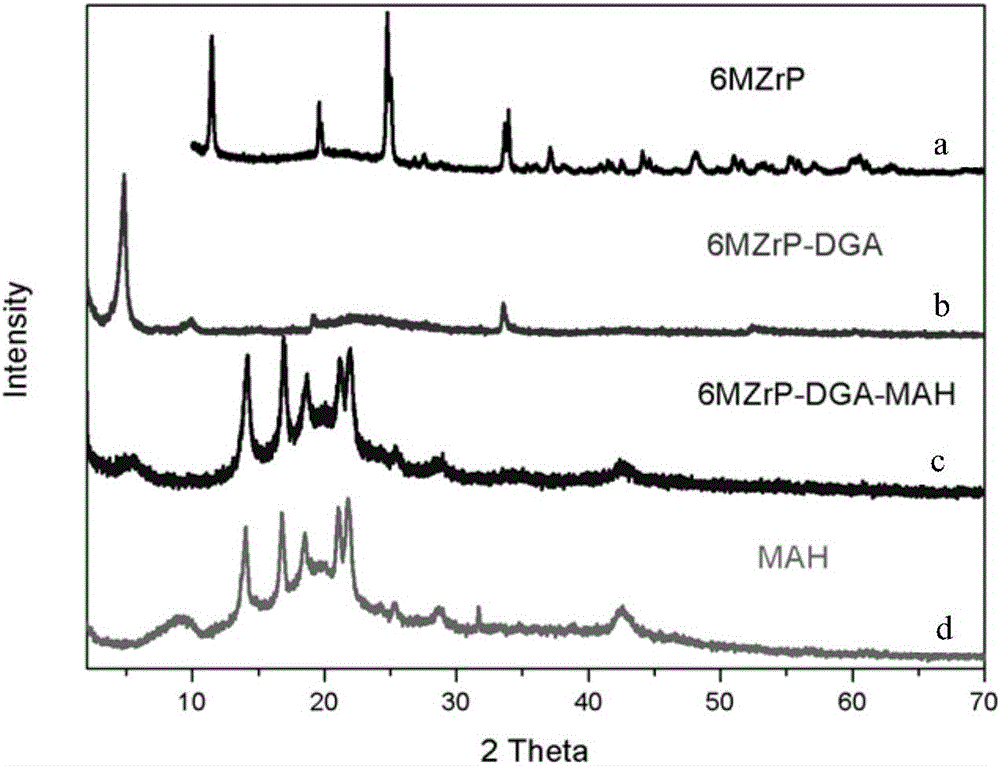

Embodiment 2

[0069] The stripping method of layered α-zirconium phosphate of the present embodiment comprises the following steps:

[0070] (1') preparing layered α-zirconium phosphate;

[0071] (1'a) Weigh 4.0g ZrOCl 2 ·8H 2 O, the preparation of 40ml concentration is 6mol / L phosphoric acid solution; ZrOCl 2 ·8H 2 O and phosphoric acid were poured into the Teflon reactor together and stirred for 3 minutes to obtain a reaction mixture;

[0072] (1'b) Put the Teflon reaction kettle into the oven and react at 200°C for 24 hours. After cooling to room temperature naturally, wash with deionized water for 3 times, then put the prepared precipitate into the oven and dry it at 75°C. Dry for 24 hours, and then grind the dried product to obtain layered α-zirconium phosphate powder.

[0073] (1) Amination treatment; Weigh 1.0g α-ZrP, pour it into 100g diglycolamine, and then mix it ultrasonically for 8 hours to obtain a mixed solution; use absolute ethanol to prepare the organic amine solution ...

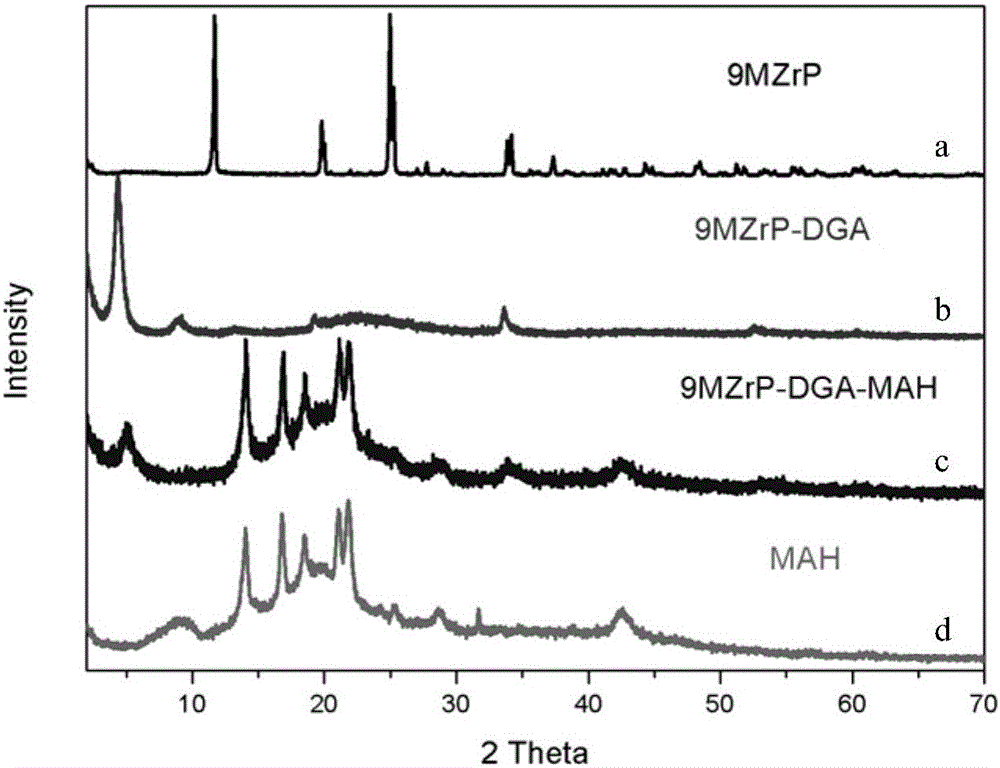

Embodiment 3

[0076] The stripping method of layered α-zirconium phosphate of the present embodiment comprises the following steps:

[0077] (1') preparing layered α-zirconium phosphate;

[0078] (1'a) Weigh 4.0g ZrOCl 2 ·8H 2 O, the preparation 40ml concentration is 9mol / L phosphoric acid solution; ZrOCl 2 ·8H 2 O and phosphoric acid were poured into the Teflon reactor together and stirred for 3 minutes to obtain a reaction mixture;

[0079] (1'b) Put the Teflon reaction kettle into the oven and react at 200°C for 24 hours. After cooling to room temperature naturally, wash with deionized water for 3 times, then put the prepared precipitate into the oven and dry it at 75°C. Dry for 24 hours, and then grind the dried product to obtain layered α-zirconium phosphate powder.

[0080] (1) Amination treatment; weigh 1.0g α-ZrP, pour it into 100g diglycolamine, and then mix it ultrasonically for 8 hours to obtain a mixed solution; use absolute ethanol to centrifugally wash the organic amine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com