Dust removal and filtering device for chemical workshop

A filter device and workshop technology, applied in the direction of dust removal, combination device, separation device, etc., can solve the problems of pollution, chemical dust cannot be recycled and reused in the environment, and achieve reduced pollution, excellent high temperature resistance, improved recovery rate and filtration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

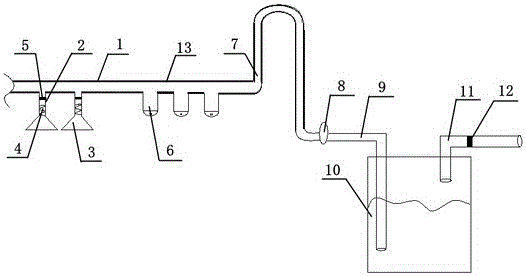

[0015] Such as figure 1 As shown, a dust removal and filtering device for a chemical workshop includes a dust suction main pipe 1, and the dust suction main pipe 1 is vertically installed with a dust suction branch pipe 2 downwards, and 1 to 4 frustum-shaped round pipes are installed at the end of the dust suction branch pipe 2 The dust collection cover 3, the upper end of the dust collection cover 3 is connected with the dust suction branch pipe 2 through the bellows 4, so the height of the dust collection cover 3 can be adjusted through the bellows 4, so that it can reach the optimal distance with the pollution source; An air volume control valve 5 is also installed on the dust suction branch pipe 2, which can adjust the air volume according to actual production needs; a group of dust receivers 6 are arranged at intervals on the dust suction main pipe 1, and the dust receivers 6 Located below and connected to the dust suction main pipe 1, the dust receivers 6 are in groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com