Grinding wheel disassembling and assembling machine with Teflon heat insulation cloth and disassembling and assembling method of grinding wheel disassembling and assembling machine

A method of disassembly and assembly of grinding wheels, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve problems such as inability to synchronize, laborious manual disassembly and separation, and soaring production costs of disassembly machines, so as to save the number of layouts , reduce production costs, and avoid the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

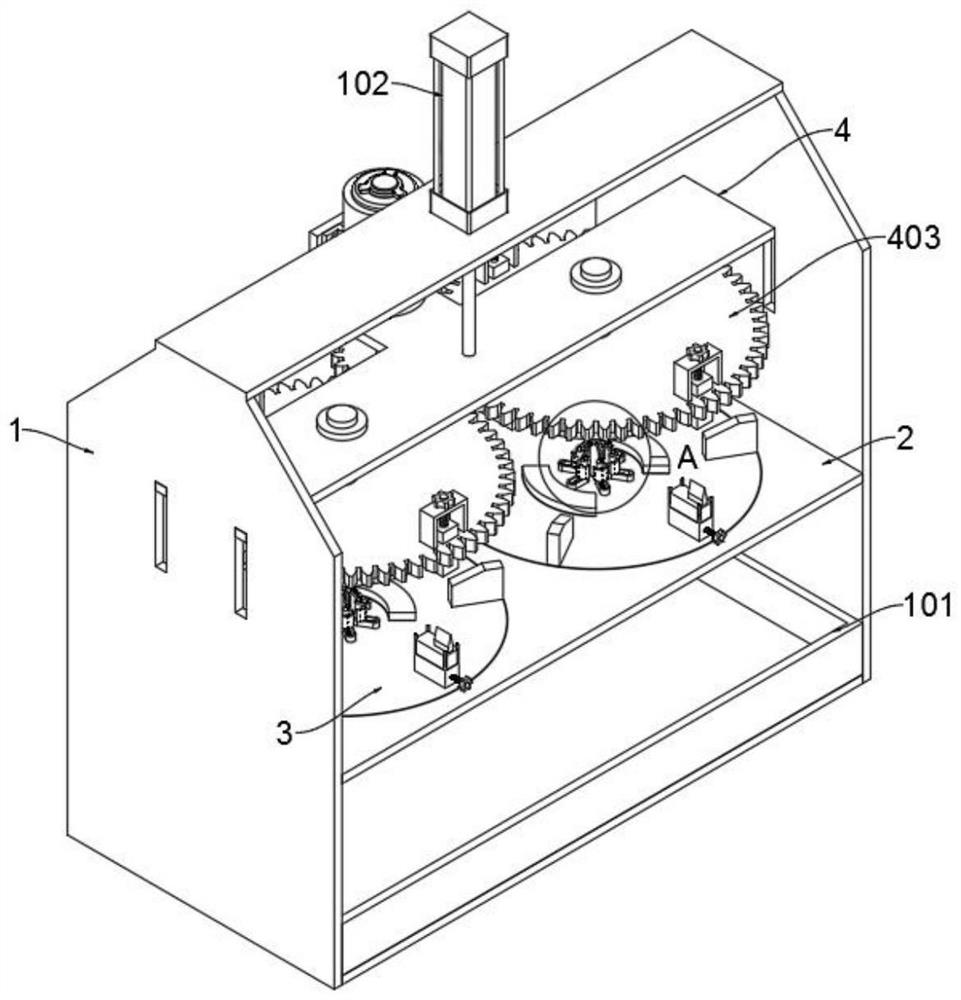

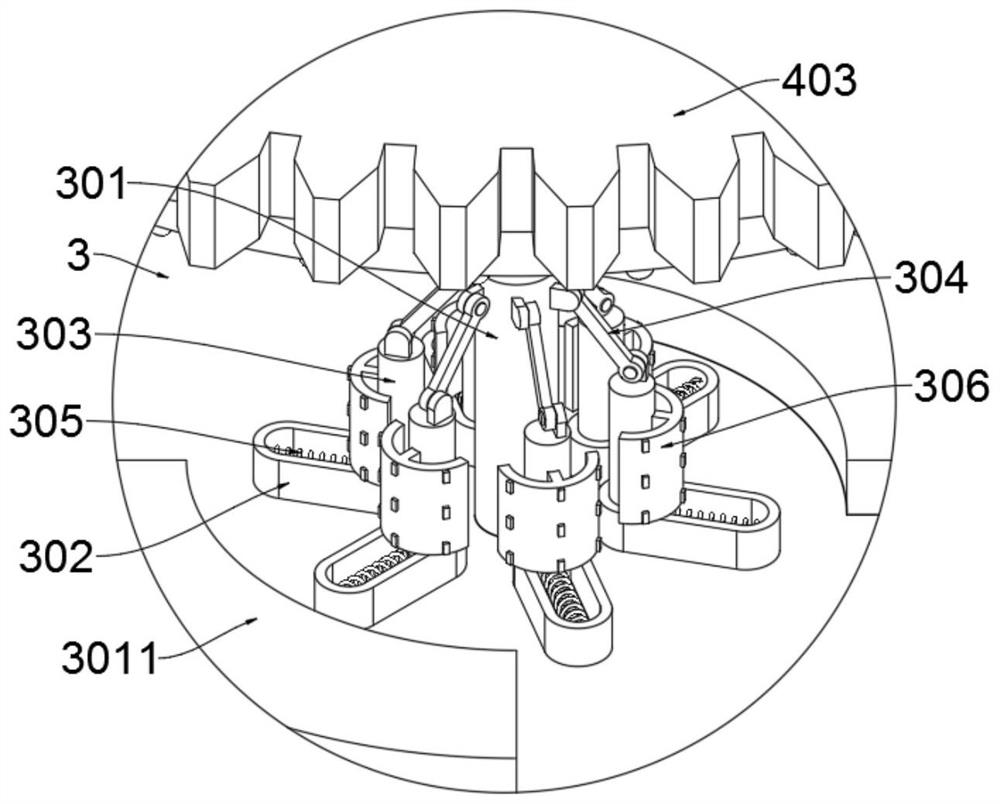

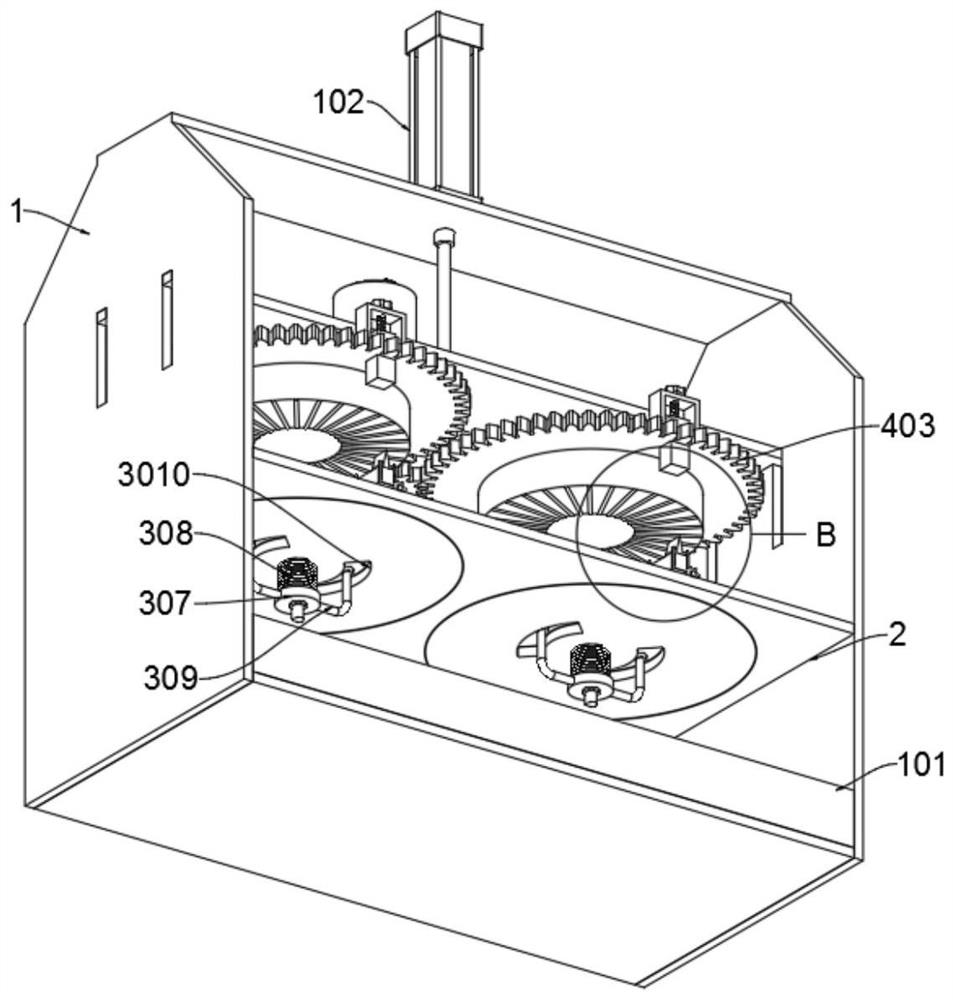

[0039] Example: Please refer to Figure 1 to Figure 8 :

[0040]The present invention proposes a grinding wheel disc dismantling machine with Teflon heat-insulating cloth and its dismantling method, comprising: a main body frame 1, the inner bottom of the main body frame 1 is provided with a housing box 101; the top of the main body frame 1 is provided with There is a cylinder 102; the inside of the main frame 1 is provided with a carrier plate 2, and the carrier plate 2 is a rectangular structure; the top of the carrier plate 2 is provided with a circular groove, and the inside of the circular groove is provided with a loading plate 3; the loading plate 3 is a disc shaped structure; the left and right sides of the main frame 1 are provided with chutes, and the loose frame 4 is slidably installed inside the chute; the top of the loose frame 4 is connected with the bottom end of the cylinder 102; The frame 5 is installed, and the loose frame 4 is pressed down by the cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com