A high-performance anti-warping glass fiber reinforced pbt/asa alloy material

An alloy material and anti-warping technology, which is applied in the field of high-performance anti-warping glass fiber reinforced PBT/ASA alloy materials, can solve the problems of product warping, inconsistent longitudinal and transverse shrinkage, etc., to achieve easy molding and improve anti-warping The effect of curved performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

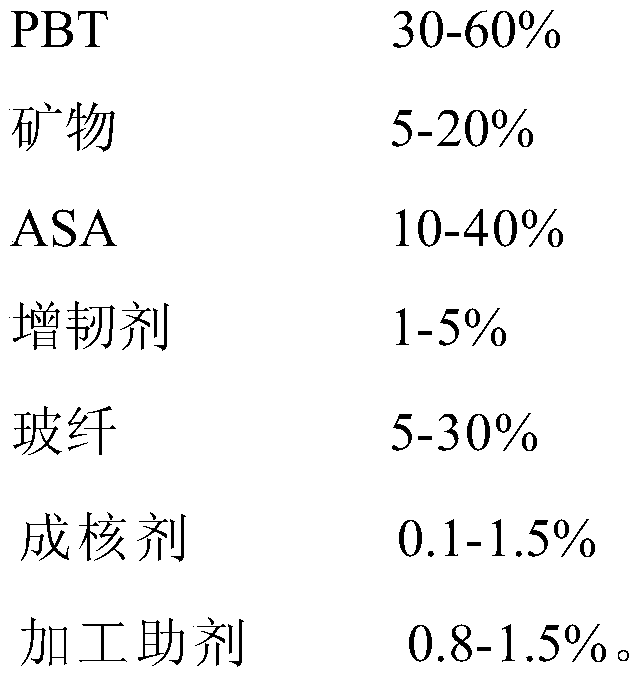

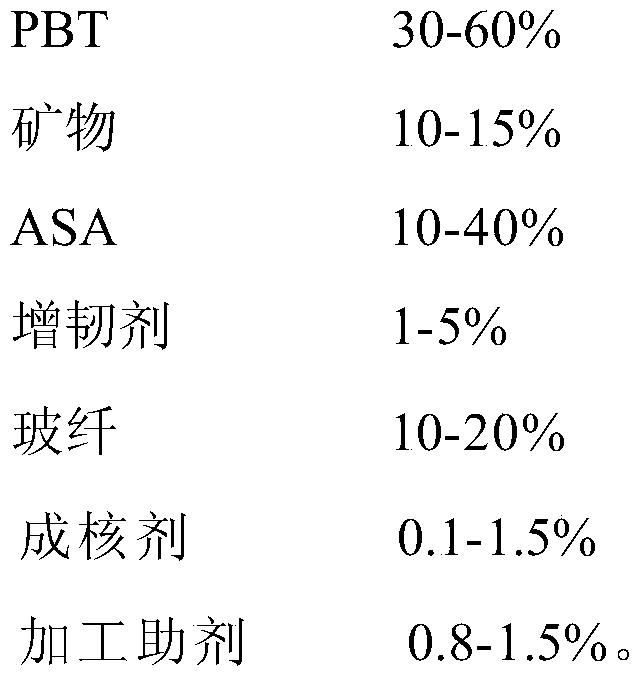

Method used

Image

Examples

Embodiment 1-5

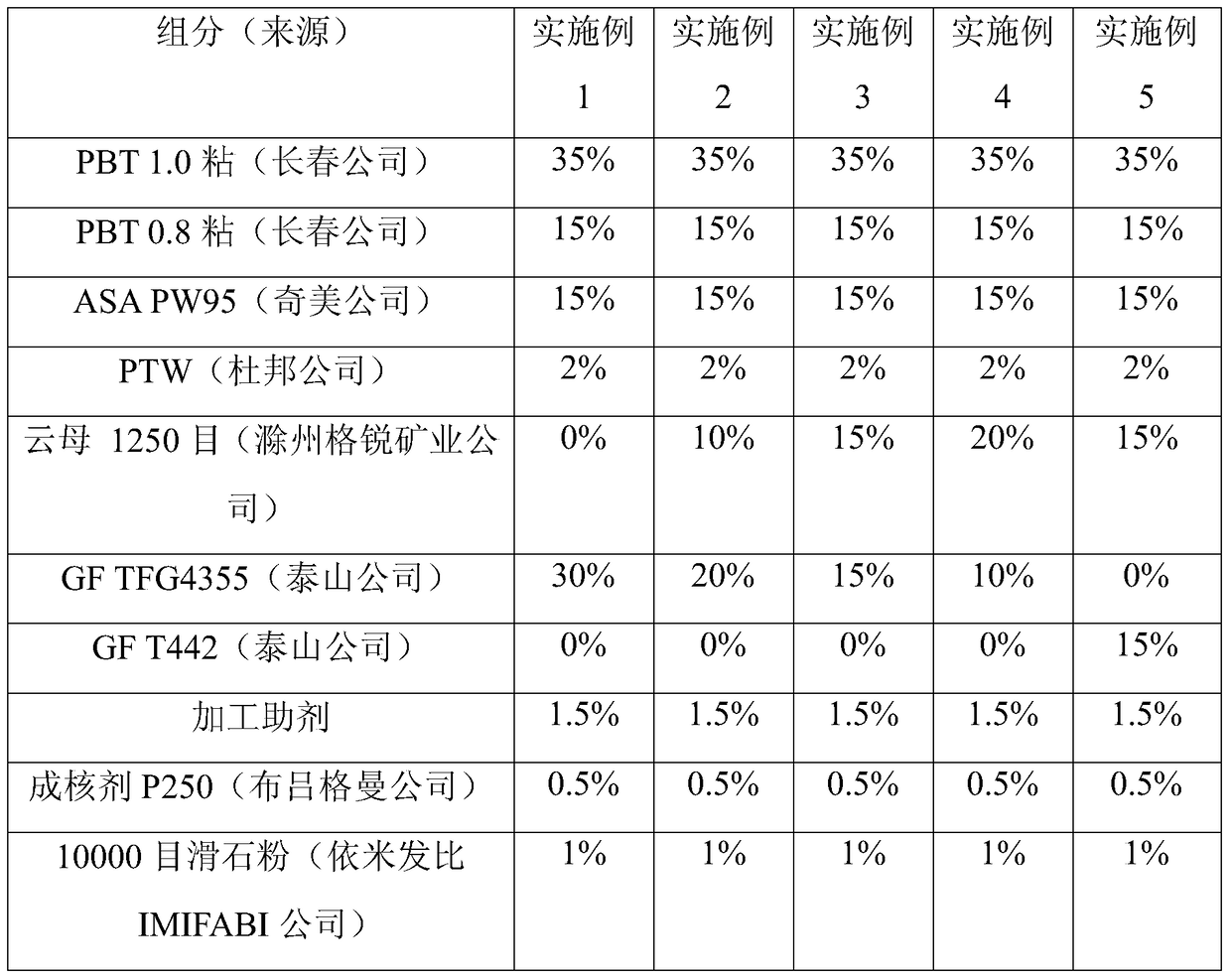

[0030] Add PBT resin, ASA resin, minerals and various additives to the high-speed mixer and stir at high speed for 2 minutes, then add it to the main feeder of the extruder, add glass fiber from the side feed button, and finally enter the twin-screw extrusion Carry out basic granulation in the machine. The temperature distribution of the extruder is as follows: from the feed section to the head: 210°C, 245°C, 245°C, 240°C, 235°C, 230°C, 230°C, 220°C, 210°C, die head: 245°C , After the material is extruded, it is water-cooled, pelletized, and then packaged. The pellets were placed in a blast drying oven and dried at 90°C for 4 hours, and then the test specimens were prepared by an injection molding machine.

[0031] The parts by weight of each raw material of Examples 1-5 are shown in Table 1.

[0032] Table 1 The parts by weight of raw materials of Examples 1-5

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com