A kind of temperable three-silver low-e glass and its tempering process

A treatment process and glass technology, applied in the field of triple-silver LOW-E glass and its tempering process, can solve problems such as uneven fragmentation, large tempering deformation, and difficulty in controlling the tempering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

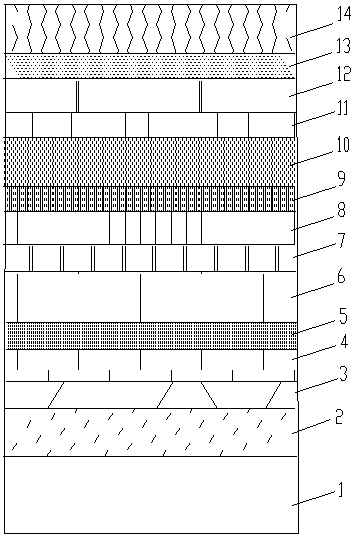

[0034] see figure 1 , a temperable triple-silver LOW-E glass according to the present invention, comprising: a glass substrate 1 and a first dielectric film layer 2 and a first barrier layer stacked on the upper surface of the glass substrate 1 from bottom to top Layer 3, first silver layer 4, second barrier layer 5, second dielectric film layer 6, third barrier layer 7, second silver layer 8, fourth barrier layer 9, third dielectric film layer 10, fifth barrier layer layer 11, the third silver layer 12, the sixth barrier layer 13 and the fourth dielectric film layer 14; the first dielectric film layer 2 is Si 3 N 4layer, the second dielectric film layer 6 is an ITO indium tin oxide layer, the third dielectric film layer 10 is a chromium oxide film layer, and the fourth dielectric film layer 14 is a Si 3 N 4 layer; the first to sixth barrier layers are Cu-N layer or Cu-O layer.

[0035] Further, in the first and second barrier layers 3 and 5, the N content in the Cu-N laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com