Children shoes and manufacturing process thereof

A production process and technology for children's shoes, which is applied in the direction of shoe uppers, footwear, heel pads, etc., can solve the problems of foot compression and unfavorable normal development of children's feet, so as to reduce pressure, maintain the shape of the upper, and ensure normal development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

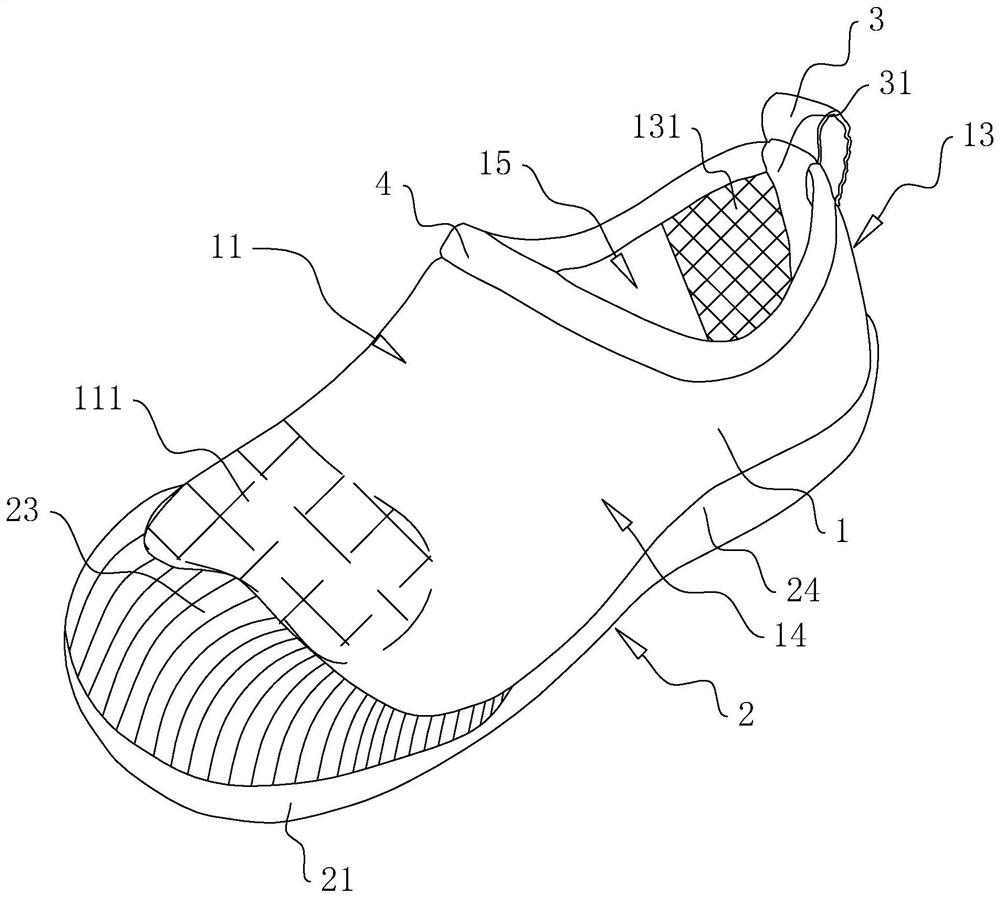

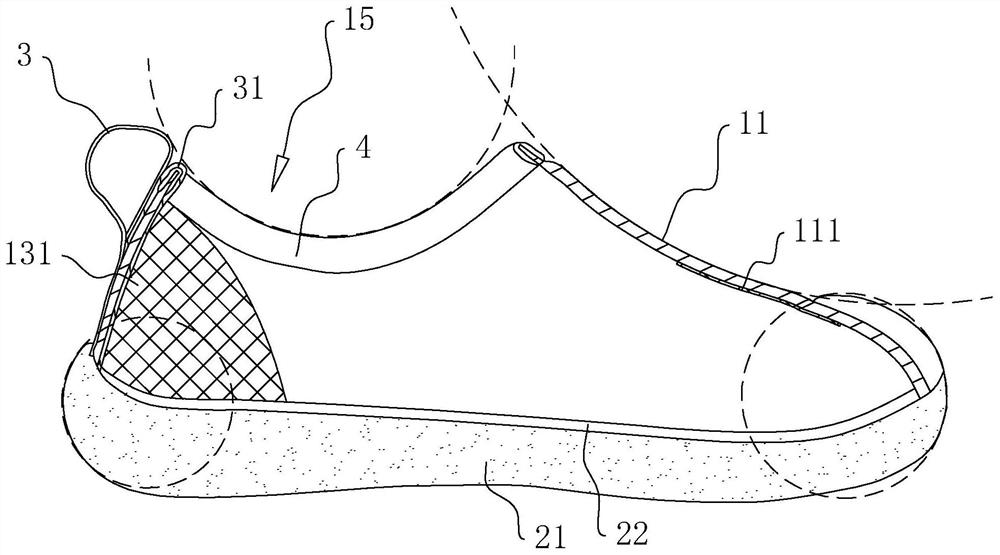

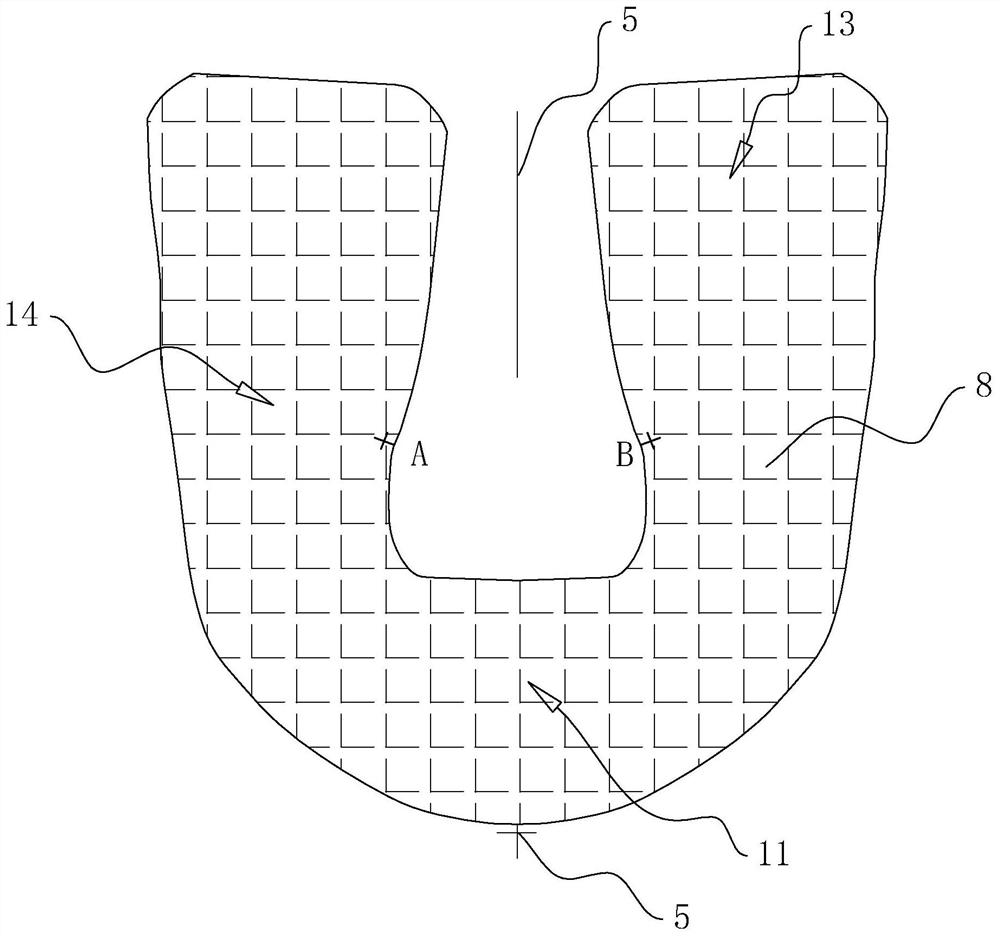

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the application discloses children's shoes. refer to figure 1 , children's shoes include an upper 1 and a sole 2.

[0044] The vamp 1 includes a dorsal portion 11 , a heel portion 13 and a foot side portion 14 .

[0045] refer to figure 2 The vamp 1 is formed by sewing an elastic vamp 8 at the heel 13 , and the vamp 8 encloses an inner cavity and a shoe opening 15 for the human foot to wear. The vamp sheet 8 is connected by three layers of glue and sewing of elastic lycra cloth, high resilience sponge and skin-friendly velvet cloth. The edge of the vamp sheet 8 located at the shoe mouth 15 is covered and stitched with the edge strip 4 .

[0046]The edging strip 4 is rectangular, and the length of the edging strip 4 stitched at the edge of the instep 11 is greater than the arc length of the instep 11 at the shoe opening 15 in an unstressed state, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com