PR<3+>:Y2SiO5/TiO2 photocatalytic composite film based on glass fiber filter film carrier, preparation method and application thereof

A technology of glass fiber and composite film, which is applied in the field of optical materials, can solve the problems of energy consumption of suspended nano-catalysts in post-processing, limited light penetration into suspensions, easy aggregation and sedimentation of powders, etc., to achieve improved photocatalytic performance and good chemical stability , the effect of combining moderate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

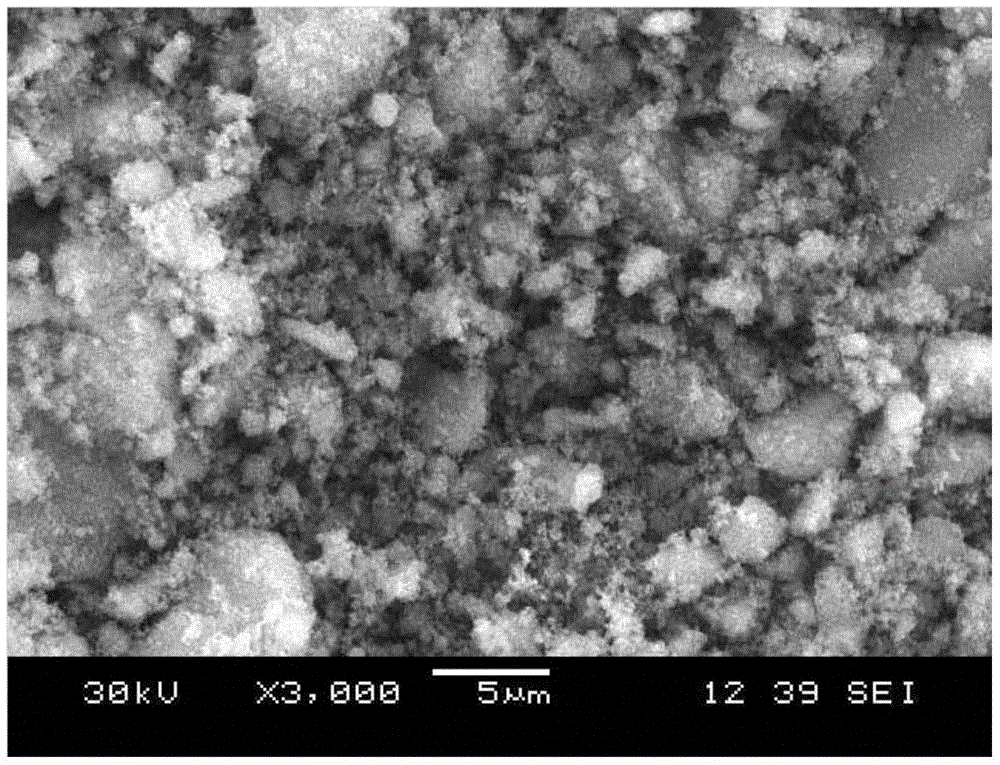

[0043] Pr 3+ :Y 2 SiO 5 / TiO 2 Preparation of photocatalytic composite film

[0044] (1) Preparation of Pr by sol-gel method 3+ 1.0% (mol) of Pr 3+ :Y 2 SiO 5 , Take Y 2 O 3 Join HNO 3 Medium configuration Y (NO 3 ) 3 Solution, accurately measure Pr(NO 3 ) 3 Join Y(NO 3 ) 3 The solution is heated and boiled in an electric furnace. The white anhydrous nitrate is obtained by evaporating and drying in an oven for several hours; adding distilled water and absolute ethanol to completely dissolve it, adding TEOS and stirring for 30 minutes, and then putting it in a water bath at 80℃ to heat to form a gel; Dry in an oven at 104°C for 12 hours to obtain a dry gel and grind it into powder. Place it in a muffle furnace at 950°C for 3 hours and then cool to obtain 1.0% (mol) Pr 3+ :Y 2 SiO 5 Powder.

[0045] (2) Prepare titanium dioxide sol by the sol-gel method, use tetrabutyl titanate as the precursor, dissolve it in absolute ethanol (2V / 3), add the hydrolysis inhibitor acetylacetone, and ad...

Embodiment 2

[0049] Material performance characterization test

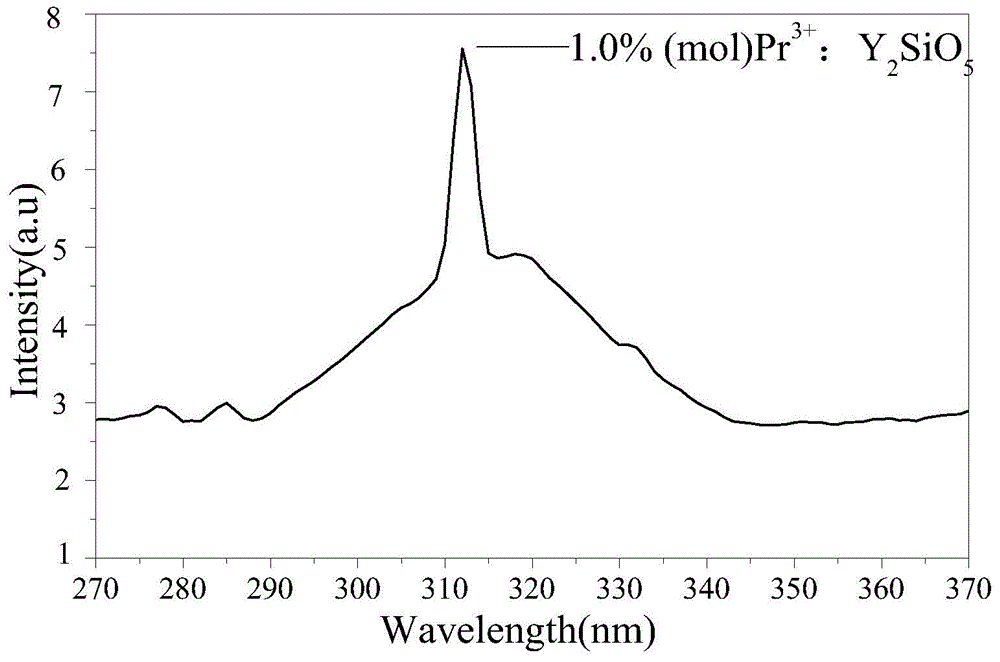

[0050] 1. 1% (mol) Pr 3+ :Y 2 SiO 5 Powder up-conversion luminescence performance test (fluorescence FS test)

[0051] Pr 3+ :Y 2 SiO 5 The up-conversion luminescence performance such as figure 2 As shown, the FL3-TCSPC fluorescence spectrometer is used to test, and the test conditions are: excitation wavelength ex=488nm, filter wavelength KV=370nm, slit width slit=1nm. Observed figure 2 It can be seen that at the excitation wavelength ex=488nm, 1% (mol) Pr 3+ :Y 2 SiO 5 The powder can emit strong ultraviolet light in the wavelength range of 290nm to 340nm, which can be used by nanometer titanium dioxide.

[0052] 2. X-ray diffraction analysis (XRD)

[0053] X-ray diffraction analysis such as Figure 4 As shown, the D8ADVANCE X-ray diffractometer (XRD) produced by Bruker in Germany is used for phase analysis of the sample; the test conditions are: graphite monochromator, Cu-Kα radiation, radiation wavelength λ=0.15418nm, tube volta...

Embodiment 3

[0057] Degradation performance test under visible light

[0058] 1. 1% (mol) Pr 3+ :Y 2 SiO 5 With TiO 2 Best quality ratio

[0059] First configure the nitrobenzene solution with the concentration of 1mg / L, 3mg / L, 5mg / L, 7mg / L, 10mg / L, 15mg / L, and then use the UV spectrophotometer to measure the nitrobenzene at each concentration For the absorbance of the solution, take the concentration of the nitrobenzene solution as the abscissa and the absorbance as the ordinate to make a standard curve.

[0060] Take 600ml of 5mg / L nitrobenzene solution as the target degradation solution. Under 140W intensity of the three primary colors, take the total mass of the composite material to 0.4g, of which 1% (mol) Pr 3+ :Y 2 SiO 5 With TiO 2 According to the mass ratio of 2%, 3%, 4%, 5%, 6%, and 8% as the photocatalyst, put the material into the liquid to be degraded, turn on the stirring device, protect from light for 20 minutes, the adsorption equilibrium has been reached, and then Then turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com