Application tape and protective pressure-sensitive adhesive sheet equipped with application tape

A technology of adhesive sheet and tape, applied in the direction of film/sheet-like adhesive, adhesive, adhesive type, etc., which can solve the problems of position offset, poor surface followability, and inability to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

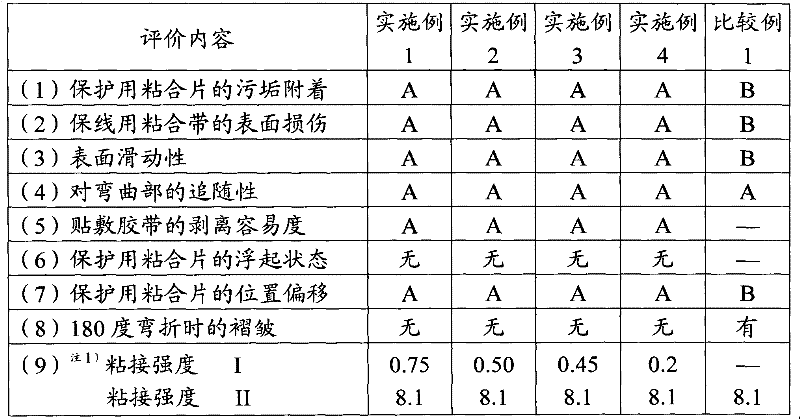

Examples

Embodiment 1

[0132] Production of application tape

[0133]As a support, a film formed of a soft polyvinyl chloride resin containing 27 parts of di-2-ethylhexyl phthalate (DOP) per 100 parts of vinyl chloride resin (degree of polymerization (P) = 1050) was obtained (70 μm thick).

[0134] One side of the obtained film is coated with a silicone resin using toluene as a solvent, and then dried at 150° C. for 1 minute to obtain 0.1 g / m 2 The backside treatment layer.

[0135] Use 100 parts of acrylic copolymer (BA / AN / AA=85 parts / 15 parts / 2.5 parts) (Mw=800000), 10 parts of butanol-modified melamine formaldehyde resin ("Super Beckamine J-820 -60N", manufactured by Japan Polyurethane Industry Co., Ltd.) and 60 parts of di-2-ethylhexyl phthalate (DOP) to make acrylic adhesive. This acrylic adhesive was dissolved in toluene to prepare an adhesive solution, and this adhesive solution was applied to one side of the support (the side to which the silicone resin was not applied) and dried at 130...

Embodiment 2

[0151] The application tape was produced in the same manner as in Example 1 except that the thickness of the support body was changed from 70 μm to 110 μm in the production process of the application tape of Example 1.

[0152] That is, as a support, a soft polyvinyl chloride resin containing 27 parts of di-2-ethylhexyl phthalate (DOP) relative to 100 parts of vinyl chloride resin (degree of polymerization (P) = 1050) was obtained. film (110 μm thick). One side of the obtained film is coated with a silicone resin using toluene as a solvent, and then dried at 150° C. for 1 minute to obtain 0.1 g / m 2 The backside treatment layer.

[0153] Next, an adhesive layer was laminated in the same manner as in Example 1. That is, 100 parts of acrylic copolymer (BA / AN / AA=85 parts / 15 parts / 2.5 parts) (Mw=800000), 10 parts of butanol-modified melamine formaldehyde resin (Super Beckamine J -820-60N, manufactured by Nippon Polyurethane Industry Co., Ltd.) and 60 parts of di-2-ethylhexyl pht...

Embodiment 3

[0157] In the preparation process of the application tape of Example 1, except having changed the adhesive layer as follows, it carried out similarly to Example 1, and produced the application tape.

[0158] That is, as a support, a soft polyvinyl chloride resin containing 27 parts of di-2-ethylhexyl phthalate (DOP) relative to 100 parts of vinyl chloride resin (degree of polymerization (P) = 1050) was obtained. film (70 μm thick).

[0159] One side of the obtained film is coated with a silicone resin solution using toluene as a solvent, and then dried at 150° C. for 1 minute to obtain 0.1 g / m 2 The backside treatment layer.

[0160] Mix 100 parts of acrylic copolymer (BA / AN / AA=85 parts / 15 parts / 2.5 parts) (Mw=800000), 2 parts by weight of toluene diisocyanate trimethylolpropane (CORONATE L, manufactured by Nippon Polyurethane Industry Co., Ltd.), 3 parts by weight of butanol-modified melamine formaldehyde resin (Super Beckamine J-820-60N, manufactured by Nippon Polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com