Flexible polymer material coolant and preparation method thereof

A technology of flexible polymer and cold storage agent, applied in heat exchange materials, chemical instruments and methods, clothing, etc., can solve the problems of non-fit to the human body, energy waste, uneven unevenness, increase comfort, reduce costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The method for preparing the flexible polymer material cold storage agent of the present invention, the steps are as follows:

[0026] 1), under heating conditions, prepare polyvinyl alcohol solution, stir to make it dissolve;

[0027] 2), while maintaining the temperature, add propylene glycol and glycerin, and stir well after each addition;

[0028] 3), prepare borax solution, and be heated to step 1) same temperature;

[0029] 4), the borax solution is mixed with the solution obtained in step 2), and stirred evenly to obtain the cooling agent;

[0030] 5), transferred to the packaging bag to cool down to room temperature, and then frozen.

[0031] Main chemical reagent used in the present invention is as follows:

[0032] Polyvinyl alcohol (polymerization degree 1750±50) (CH 2 CHOH)n≥99.0% Sinopharm Chemical Reagent Co., Ltd.

[0033] Propylene Glycol C 3 h 8 o 2 ≥99.0% Yonghua Chemical Technology Co., Ltd.

[0034] Glycerin C 3 h 8 o 3 ≥99.5% Sinopharm C...

Embodiment 1

[0038] 1) Weigh a certain mass of polyvinyl alcohol and tap water, pour them into a three-necked flask, and stir for 2.5 hours to dissolve them in a water bath at 95° C. to obtain a 5% polyvinyl alcohol solution.

[0039] 2) Measure 50 mL of polyvinyl alcohol solution with a concentration of 5%, and maintain the temperature at 95° C., add 1.5 mL of propylene glycol, and stir thoroughly.

[0040] 3) Measure 15mL of borax solution with a concentration of 8% in tap water, place it in a water bath and heat it to 95°C, then slowly pour the borax solution into the solution in step 2) along the glass rod, pouring while pouring Stir to make it fully mixed to obtain the cooling agent.

[0041] 4) Put it in a plastic bag and seal it, cool it down to room temperature, then freeze it below -10°C for 12 hours, take it out for testing.

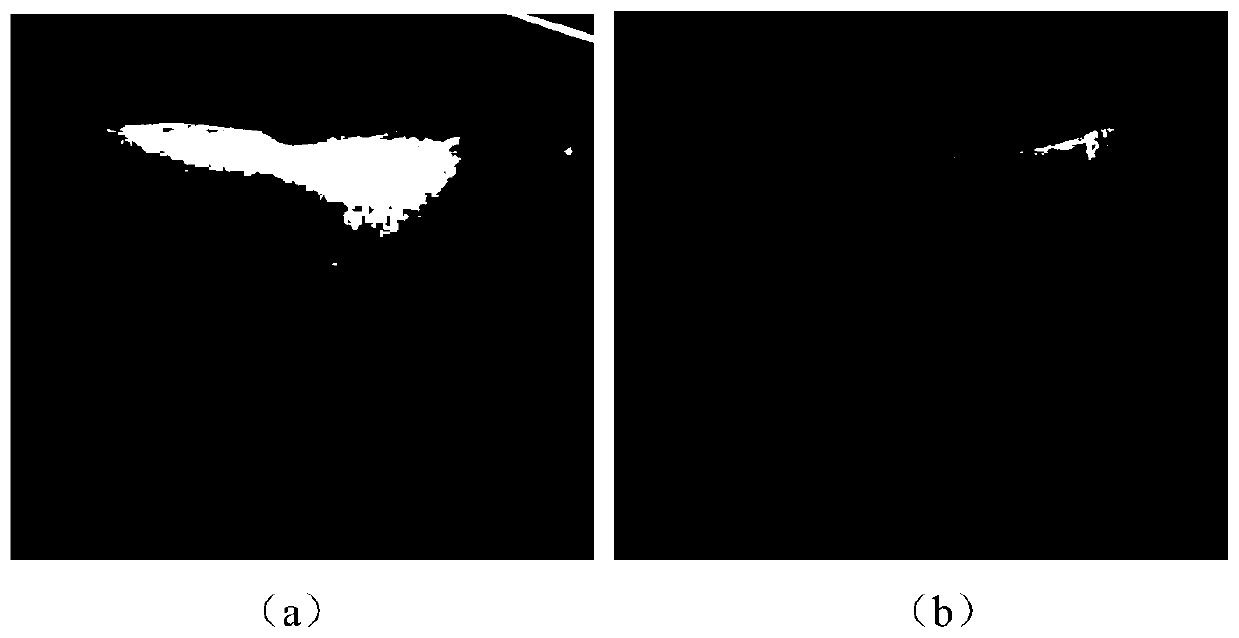

[0042] As a contrast, the cold storage agent prepared in Example 1 does not add glycerin, and its photo is as follows figure 1 As shown in a, no indentat...

Embodiment 2

[0045] 1) Weigh a certain mass of polyvinyl alcohol and tap water, pour it into a three-necked flask, and stir for 3 hours to dissolve it in a water bath at 90° C. to obtain a 5% polyvinyl alcohol solution.

[0046] 2) Measure 50 mL of polyvinyl alcohol solution with a concentration of 5%, and maintain the temperature at 95° C., add 2 mL of propylene glycol, stir well, then add 2 mL of glycerin, and stir well again.

[0047] 3) Measure 15mL of borax solution with a concentration of 10% in tap water, place it in a water bath and heat it to 90°C, then slowly pour the borax solution into the solution in step 2) along the glass rod, pouring while pouring Stir to make it fully mixed to obtain the cooling agent.

[0048] 4) Put it in a plastic bag and seal it, cool it down to room temperature, then freeze it below -10°C for 12 hours, take it out for testing.

[0049] The cold storage agent prepared in embodiment 2 added glycerin on the basis of propylene glycol, and its softness wa...

PUM

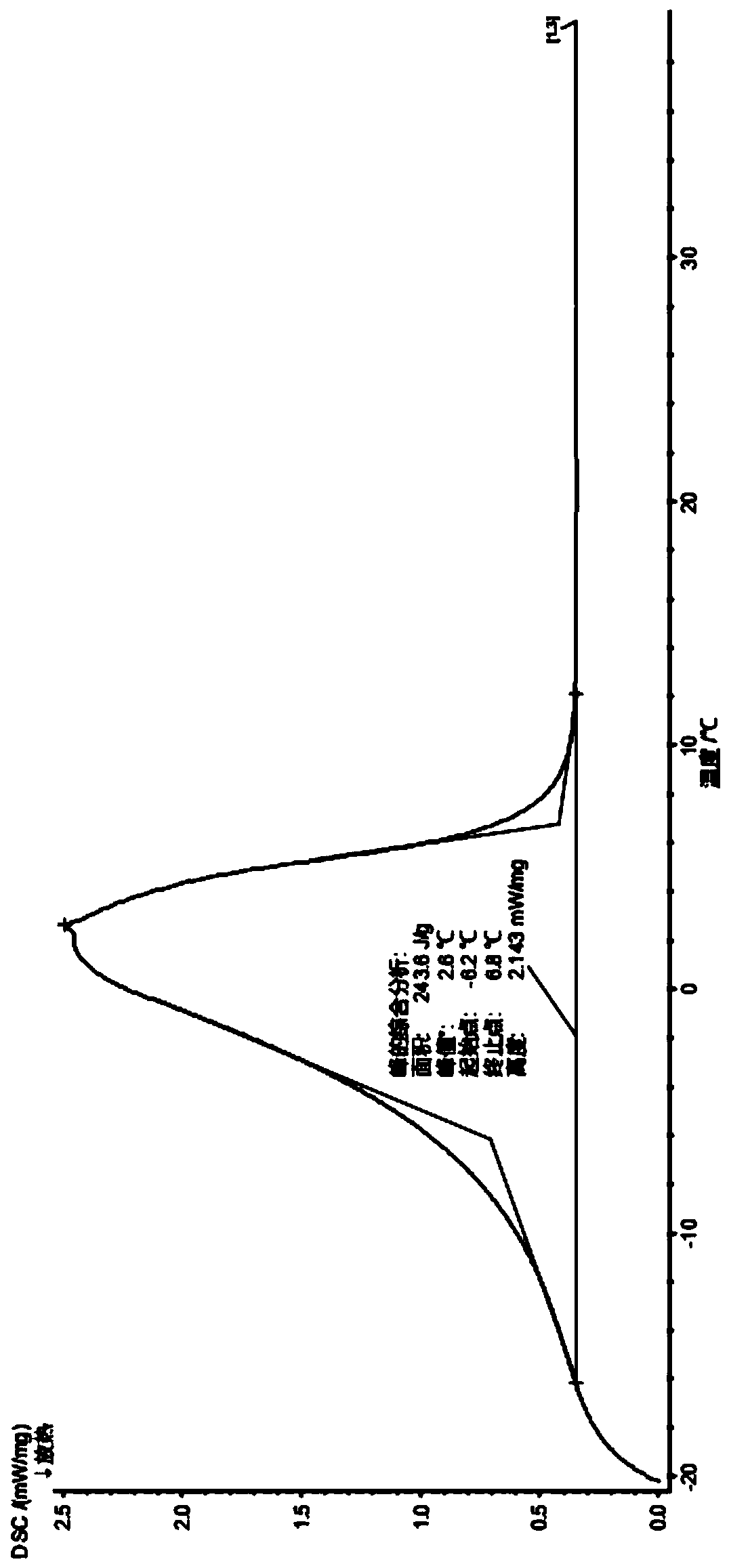

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com