Preparation of magnetic silicon dioxide microsphere with metallic ion chelated surface and use thereof

A technology of silica and metal ions, which is applied in the field of materials for separating hexahistidine proteins, can solve problems such as metal ion omission, weak interaction force, and weak protein interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

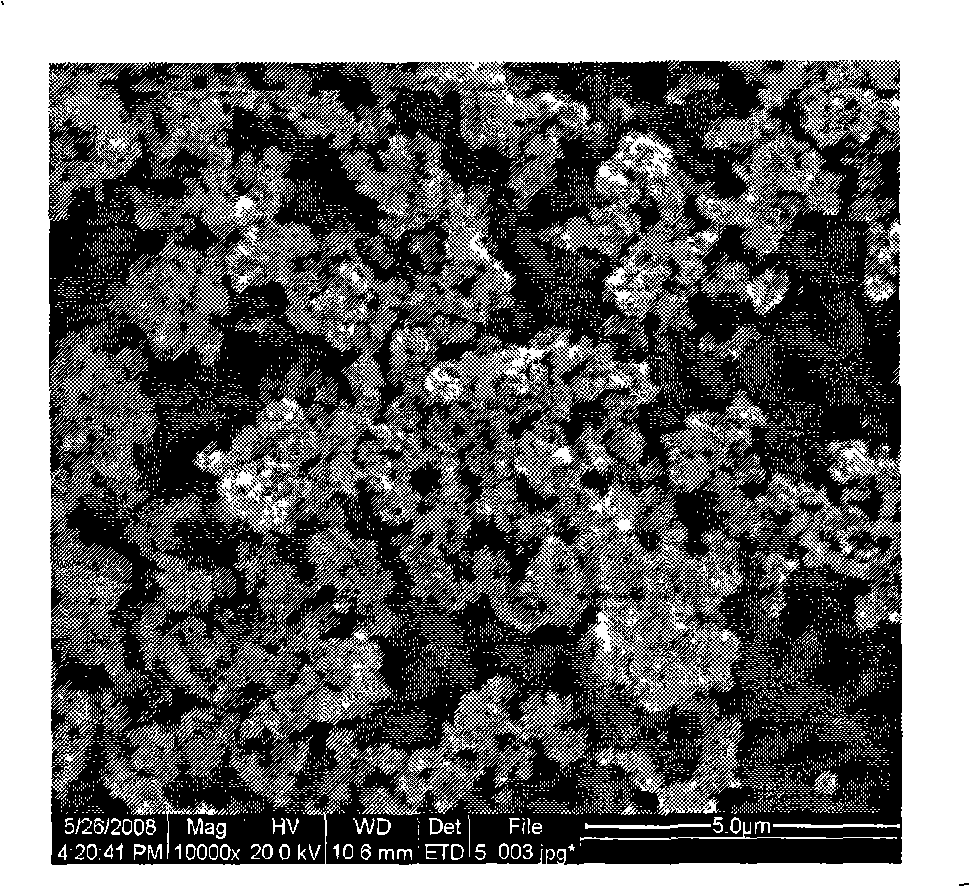

[0036] This embodiment provides the preparation method of magnetic silica microspheres with surface chelated metal ions, and its process steps are as follows:

[0037] 1. Preparation of magnetic silica microspheres

[0038] Take 7.2892g of cetyltrimethylammonium bromide and 100.0g of toluene into a four-necked flask, the mass ratio of cetyltrimethylammonium bromide to toluene is 1:15, and use a mixer to Stir well; 0.329g FeCl 2 4H 2 O with 0.987g FeCl 3 ·6H 2 O was dissolved in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 140g / L, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O mass ratio is 1:3, at 2~3mL / min N 2 Add this solution dropwise to the above mixture at 4-5mL / h under air protection, and continue stirring at 800 rpm for 4-6 hours; then add 2mL of ammonia water with a mass concentration of 25%, cetyltrimethylammonium bromide The mass ratio of ammonia water with a mass concentration of 25% is 1:0.17, and the stirring is continued at 800 rpm...

Embodiment 2

[0047] In the preparation of magnetic silica microspheres process step 1, get 7.2892g cetyltrimethylammonium bromide and 87.47g toluene and join in the four-necked flask, cetyltrimethylammonium bromide and toluene The mass ratio is 1:12, stir evenly with a stirrer at 1000 rpm; mix 0.305g FeCl 2 4H 2 O with 0.916g FeCl 3 ·6H 2 O was dissolved in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 130g / L, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O mass ratio is 1:3, at 2~3mL / min N 2 Add this solution dropwise to the above mixture at 4-5mL / h under air protection, and continue stirring at 800 rpm for 4-6 hours; The mass ratio of ammonium to ammonia water with a mass concentration of 25% is 1:0.1, and the stirring is continued at 800 rpm for 2 hours. In the mixture, ferric oxide nanoparticles are formed; slowly add ethyl orthosilicate at 2 to 3 mL / h Ester 6.78mL, hexadecyltrimethylammonium bromide and tetraethyl orthosilicate in a mass ratio of 1:1, stir...

Embodiment 3

[0052] In the preparation of magnetic silica microspheres process step 1, get 7.2892g cetyltrimethylammonium bromide and 145.784g toluene and join in the four-necked flask, cetyltrimethylammonium bromide and toluene The mass ratio is 1:20, stir evenly with a stirrer at 1000 rpm; mix 0.354g FeCl 2 4H 2 O with 1.060g FeCl 3 ·6H 2 O was dissolved in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 150g / L, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O mass ratio is 1:3, at 2~3mL / min N 2 Add this solution dropwise to the above mixture at 4~5mL / h under air protection, and continue stirring at 800 rpm for 4~6 hours; The mass ratio of ammonium to 25% ammonia water is 1:0.2, and the mixture is continuously stirred at 800 rpm for 2 hours. In the mixture, iron ferric oxide nanoparticles are formed; slowly add ethyl orthosilicate at 2 to 3 mL / h Esters 11.76mL, hexadecyltrimethylammonium bromide and tetraethyl orthosilicate at a mass ratio of 1:1.5, stirred and ...

PUM

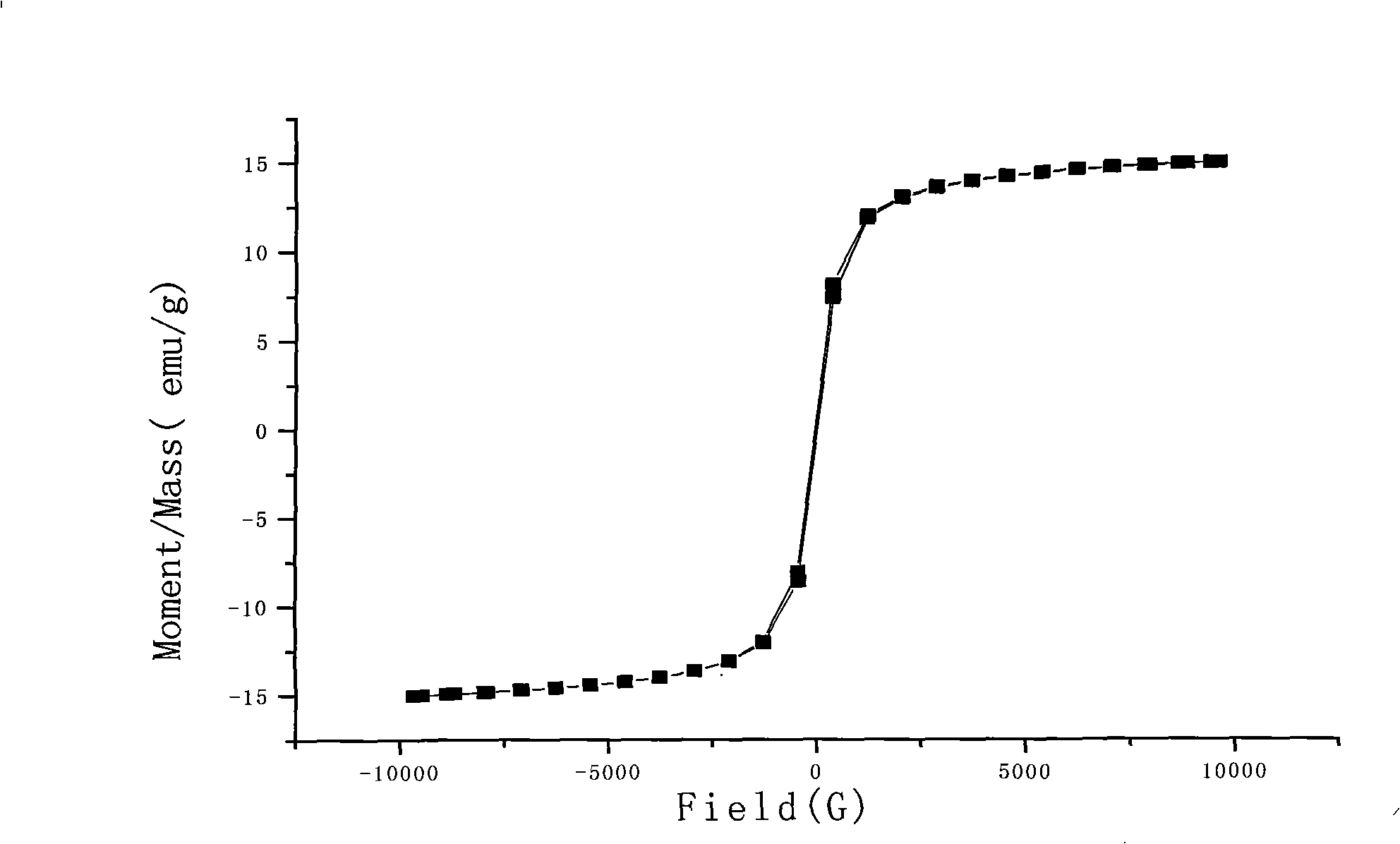

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com