Sound-insulation PVB photographic film and preparation method thereof

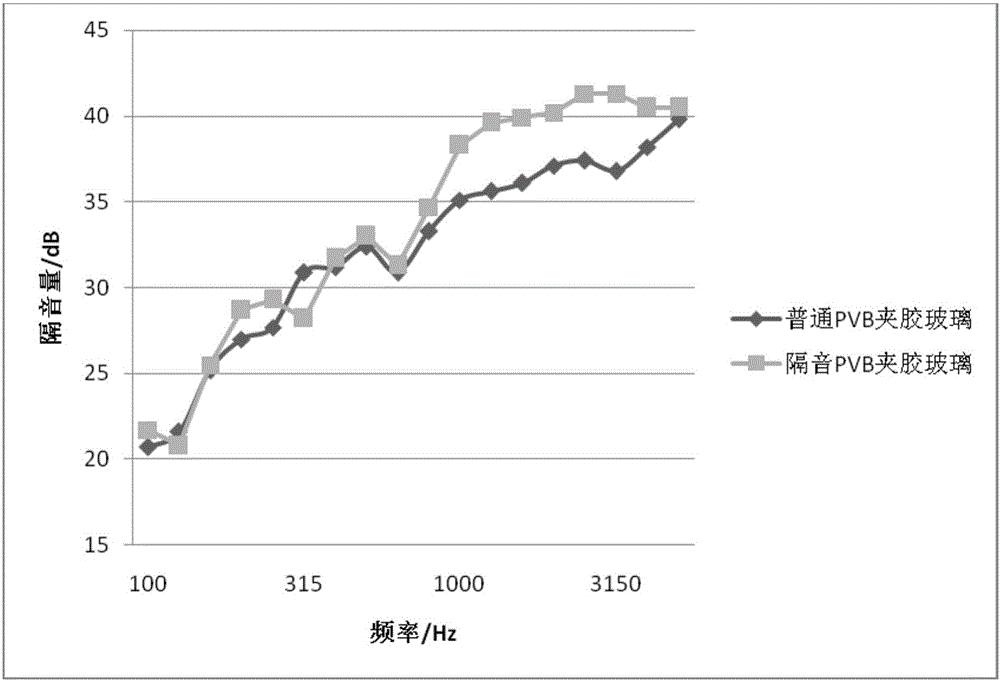

A film and modification technology, used in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve problems such as processing difficulties, reducing hydroxyl content, and difficulty in forming films with uniform thickness and uniform thickness. Uneven problem, avoid powder pollution, improve the effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

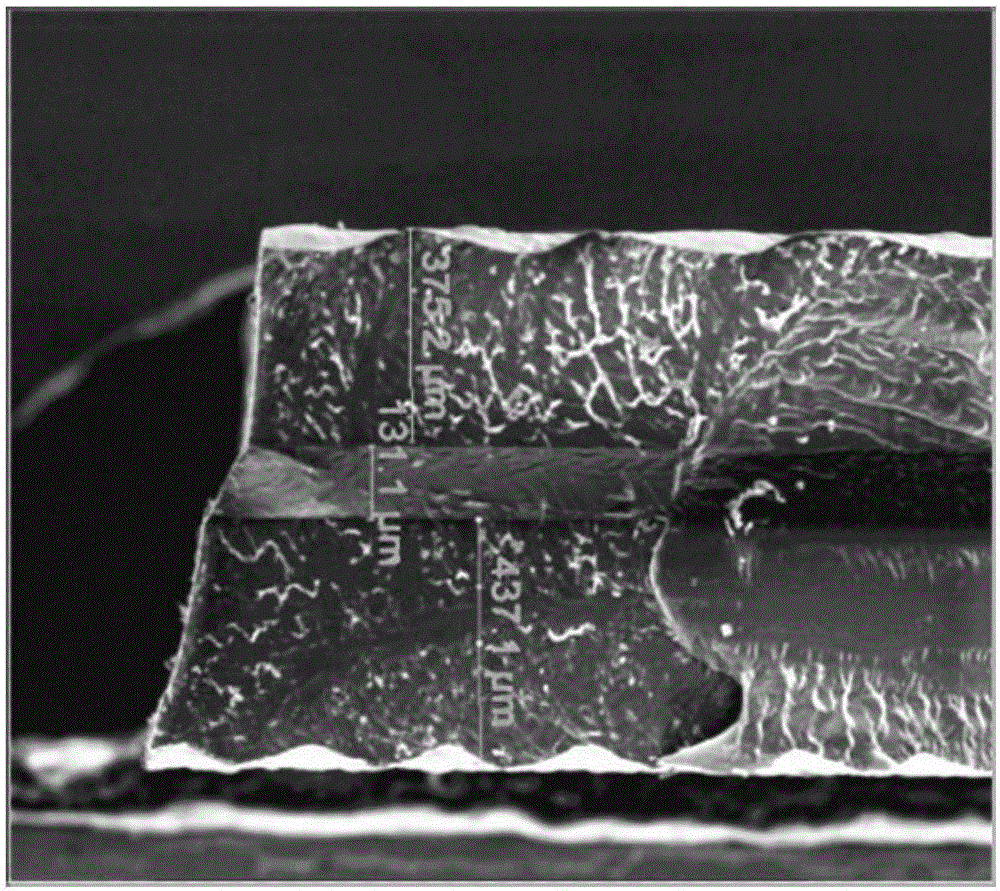

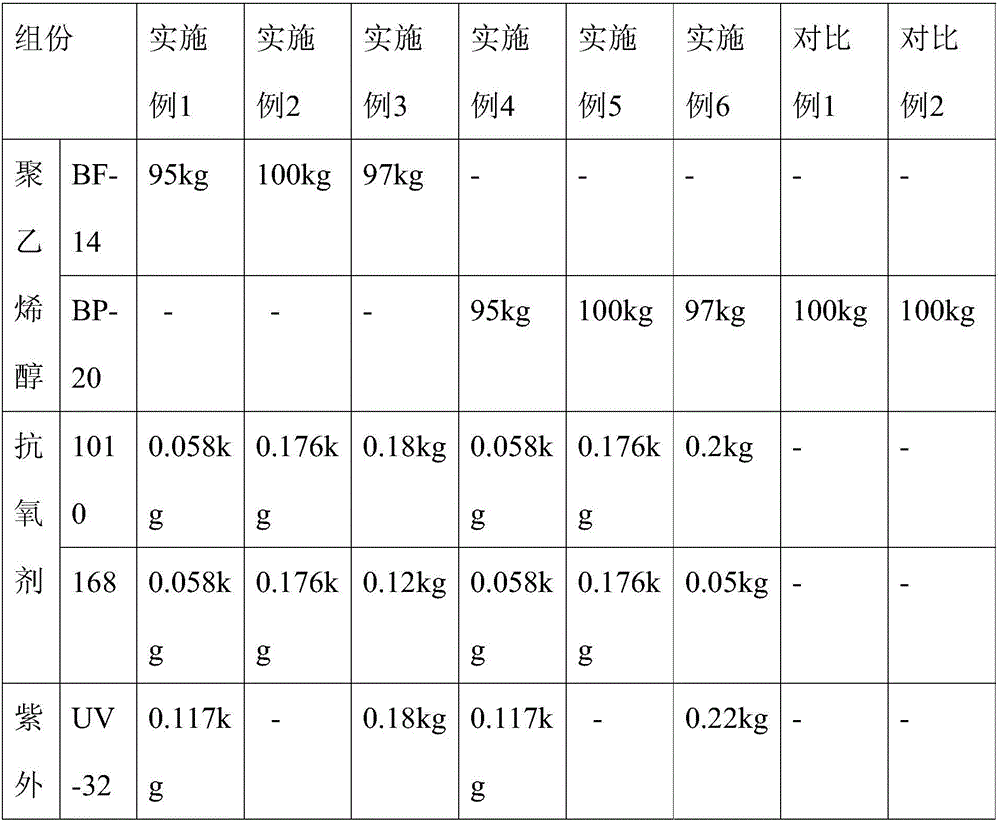

[0078] Get the modified PVB resin powder 72kg of embodiment 1, plasticizer 3G8 altogether 28kg, plasticize at the temperature of 160 ℃ by 52 type twin-screw extruders, the middle B module of plasticized resin import three-layer mould; 72kg of modified PVB resin powder in Example 5, and a total of 28kg of plasticizer 3G8 were plasticized at a temperature of 160°C by a 95-type twin-screw extruder, and then introduced into the outer layers A and C of the three-layer mold after plasticization. The PVB film with sound insulation performance is obtained by extruding into a film through a three-layer die.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com