Ultraviolet-cured liquid optical adhesive as well as preparation method and application thereof

A technology of ultraviolet light and optical glue, applied in the fields of optics, nonlinear optics, adhesives, etc., can solve the problems of contamination of the display screen, poor display, glue overflow and curing shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

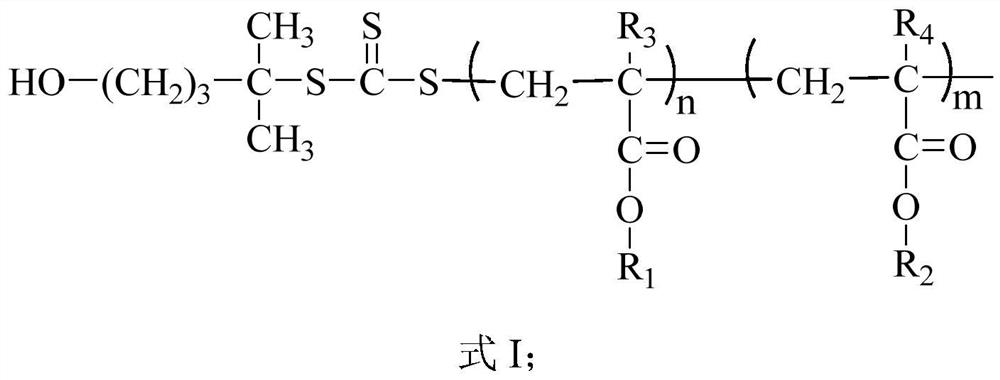

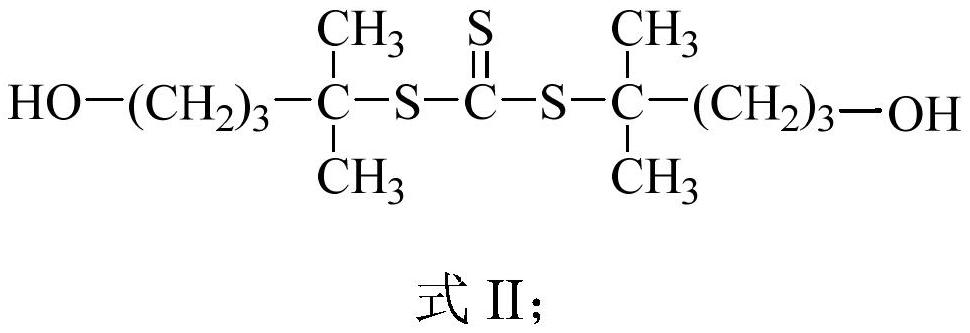

[0072] This preparation example provides a kind of tackifying resin, and described tackifying resin has the structure shown in following formula I-1:

[0073]

[0074] Formula I-1

[0075] The tackifying resin is prepared by the following method: add 2 g of dibenzoyl peroxide, 0.1 g of RAFT reagent and 500 mL of xylene into a four-necked flask with a stirrer, a temperature control device and a nitrogen protection device, and raise the temperature to 90° C. , gradually add 400g of n-butyl acrylate and 200g of glycidyl methacrylate dropwise, control the dropping time for 4h, then continue the reaction for 3.5h, and add 0.1g of N,N dimethyldipropyltriamine after the polymerization reaction is complete Carry out decolorization, finally concentrate solvent, obtain the tackifying resin shown in formula I-1.

[0076] The tackifying resin represented by Formula I-1 has a viscosity of 25000 cps, a number average molecular weight of 8100, a molecular weight polydispersity coefficien...

preparation example 2

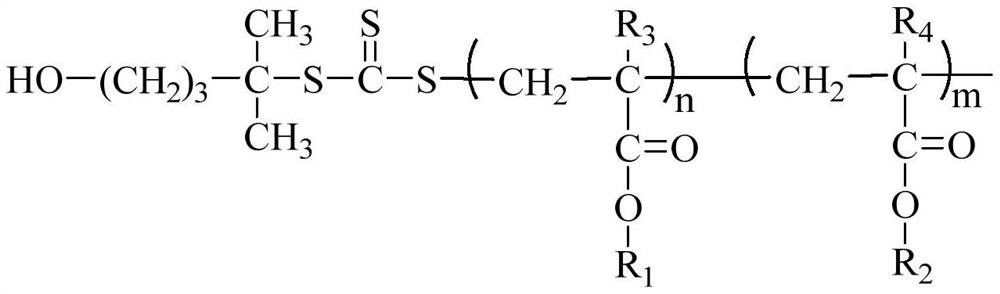

[0078] This preparation example provides a kind of tackifying resin, and described tackifying resin has the structure shown in following formula I-2:

[0079]

[0080] Formula I-2

[0081] The tackifying resin is prepared by the following method: add 5g of dibenzoyl peroxide, 0.3g of RAFT reagent and 450mL of xylene into a four-necked flask with a stirrer, a temperature control device and a nitrogen protection device, and heat up to 90°C , gradually add 230g of functional monomer hydroxyethyl methacrylate and 300g of isooctyl acrylate dropwise, control the dropping time for 4h, then continue to react for 4h, and add 0.05g of N,N dimethyldipropylene after the polymerization reaction is complete Base triamine is used for decolorization, and finally the solvent is concentrated to obtain the tackifying resin shown in formula I-2.

[0082]The tackifying resin represented by formula I-2 has a viscosity of 32000 cps, a number average molecular weight of 9300, a molecular weight p...

preparation example 3

[0084] This preparation example provides a kind of tackifying resin, and described tackifying resin has the structure shown in following formula I-3:

[0085]

[0086] Formula I-3

[0087] The tackifying resin is prepared by the following method: 2g dibenzoyl peroxide, 0.1g RAFT reagent and 400mL xylene are added to a four-necked flask with a stirrer, a temperature control device and a nitrogen protection device, and the temperature is raised to 90°C , gradually add 200g of functional monomer isobornyl methacrylate and 300g of caprolactone acrylate dropwise, control the dropping time for 4h, then continue to react for 4h, add 0.08g of N,N dimethyldipropylene Base triamine is used for decolorization, and finally the solvent is concentrated to obtain the tackifying resin shown in formula I-3.

[0088] The tackifying resin represented by formula I-3 has a viscosity of 33000 cps, a number average molecular weight of 10000, a molecular weight polydispersity coefficient of 1.23,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com