Colour wheel group

A color wheel set and color wheel technology, applied in the field of color wheel set, can solve the problems of poor dynamic balance, waste of parts, increase production cost, etc., and achieve the effect of easy dynamic balance correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The foregoing and other technical contents, features, and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

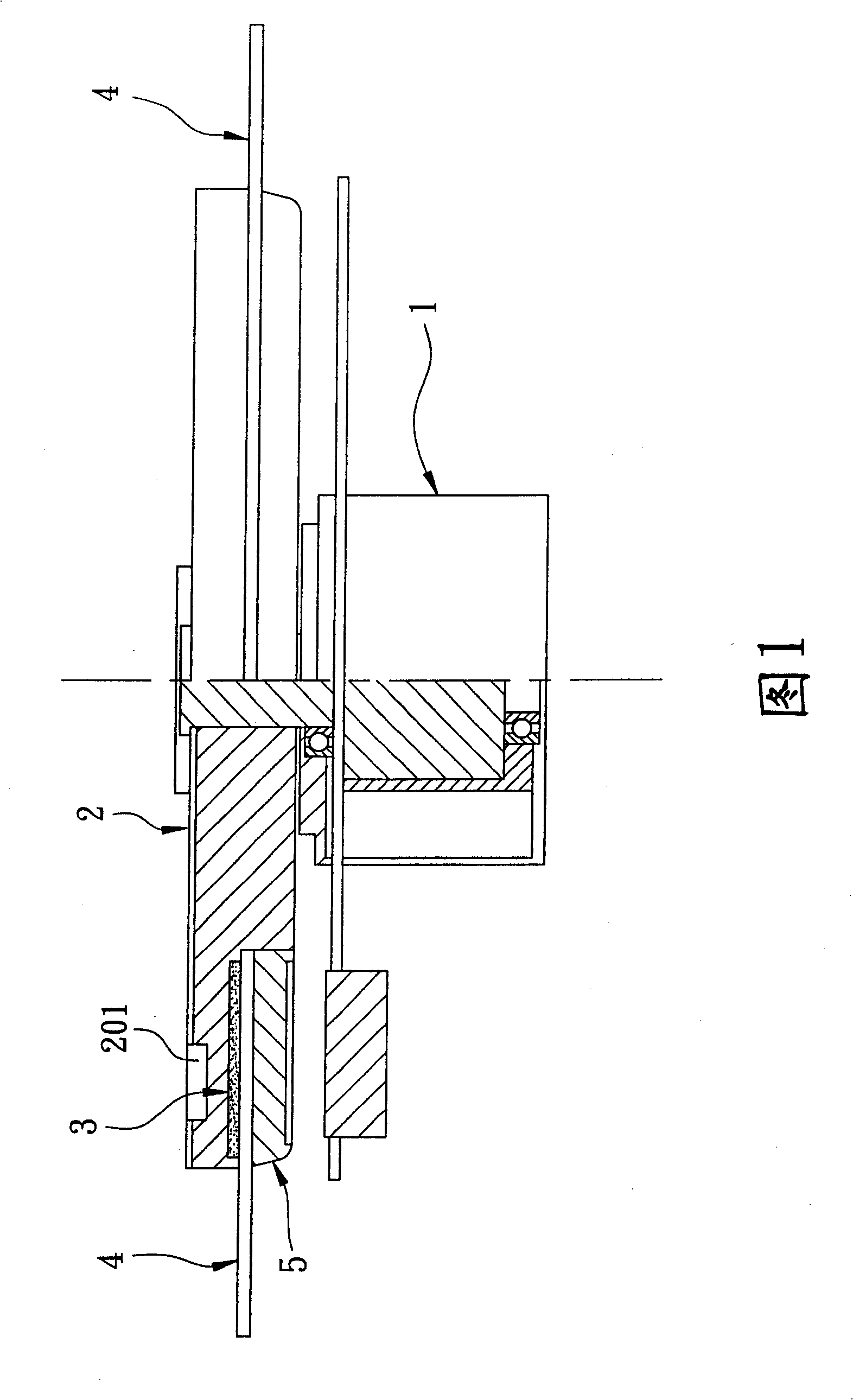

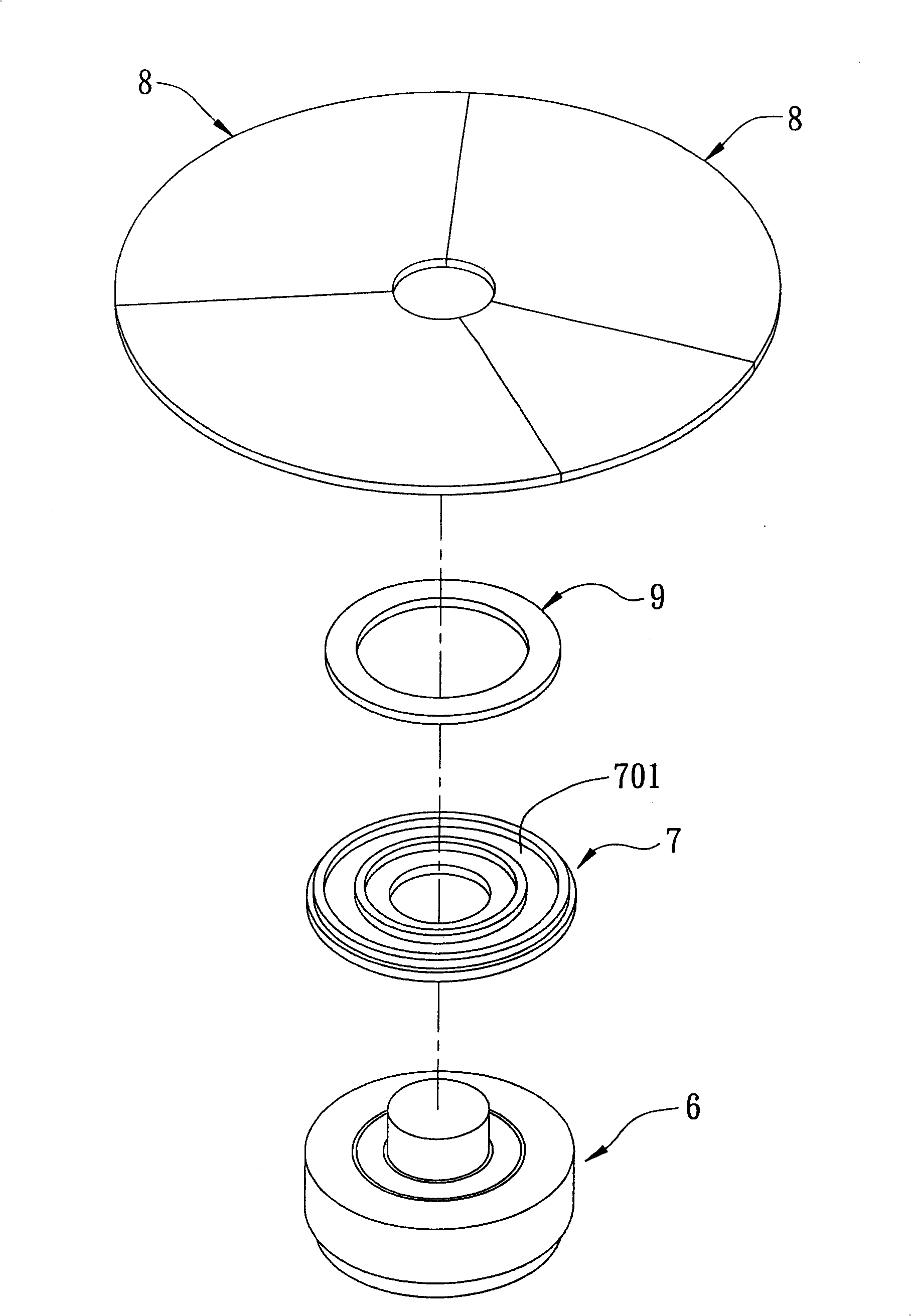

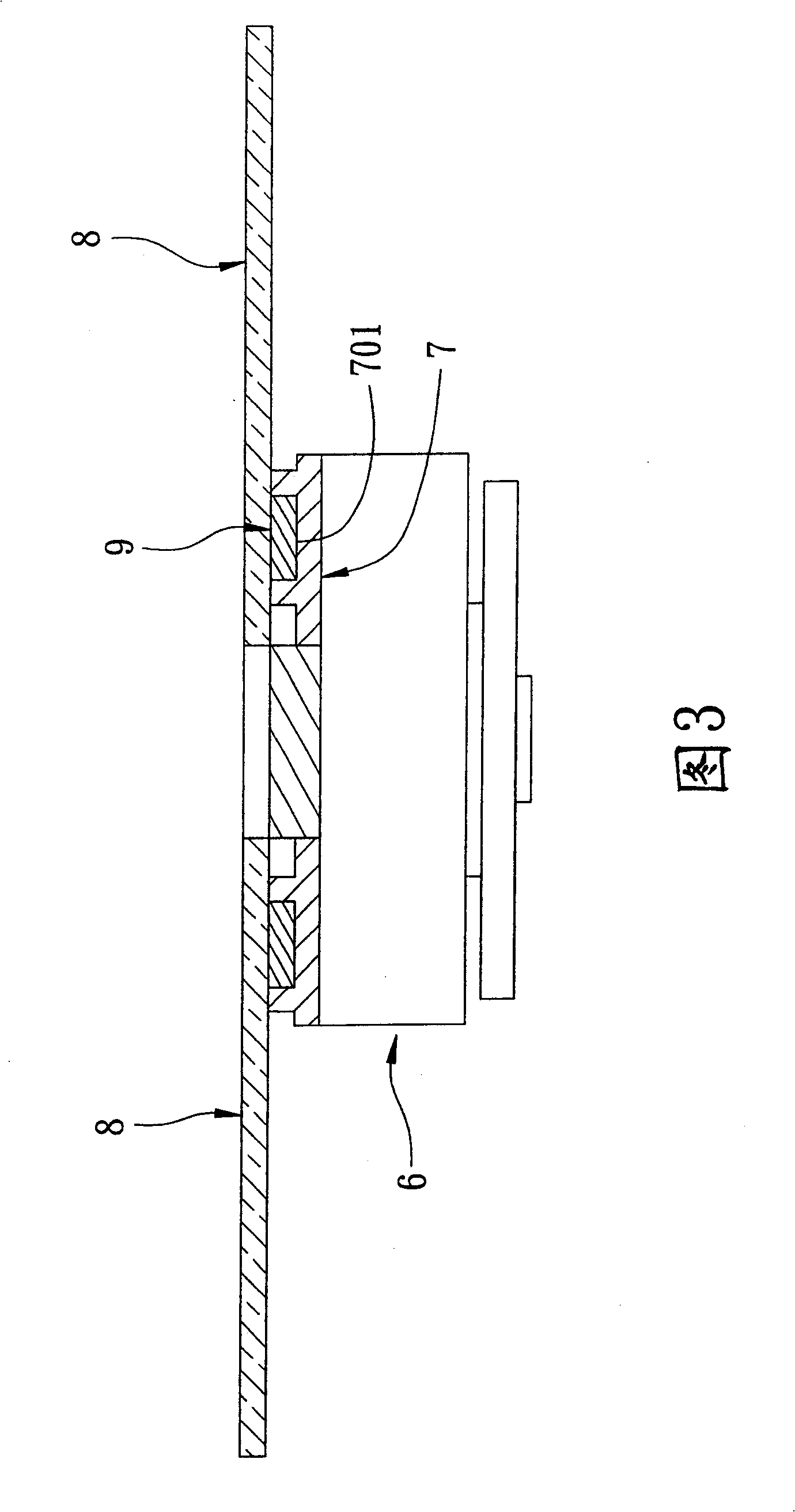

[0022] Refer to Figure 4 , 5, and 6 are preferred embodiments of the color wheel set of the present invention. The color wheel set can be installed on a motor 100 having a rotating shaft 110 and a rotor 120. The color wheel set includes: a rotating hub 10, a filter unit 20, a gland 30, a gasket 40, a joint unit 50, three bolts 60, and a balance material 70.

[0023] The rotating hub 10 is installed on the rotating shaft 110 and the rotor 120 of the motor 100, and the rotating hub 10 can be driven by the motor 100 to rotate around an axis.

[0024] The filter unit 20 has a number of filters 21 that can be grouped together, and a central hole 22. Each of the filters 21 has a top surface 211, a bottom surface 212 opposite to the top surface 211, an outer periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com