Plastic packaging mold and method based on one-time double-side plastic packaging technology and mold cleaning method of mold

A plastic sealing mold, double-sided technology, applied in the secondary processing of printed circuits, electrical components, printed circuits, etc., can solve the problem that double-sided plastic sealing molds cannot solve the problems of plastic sealing overflow and mold cleaning at the same time, so as to improve the cleaning efficiency. , the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

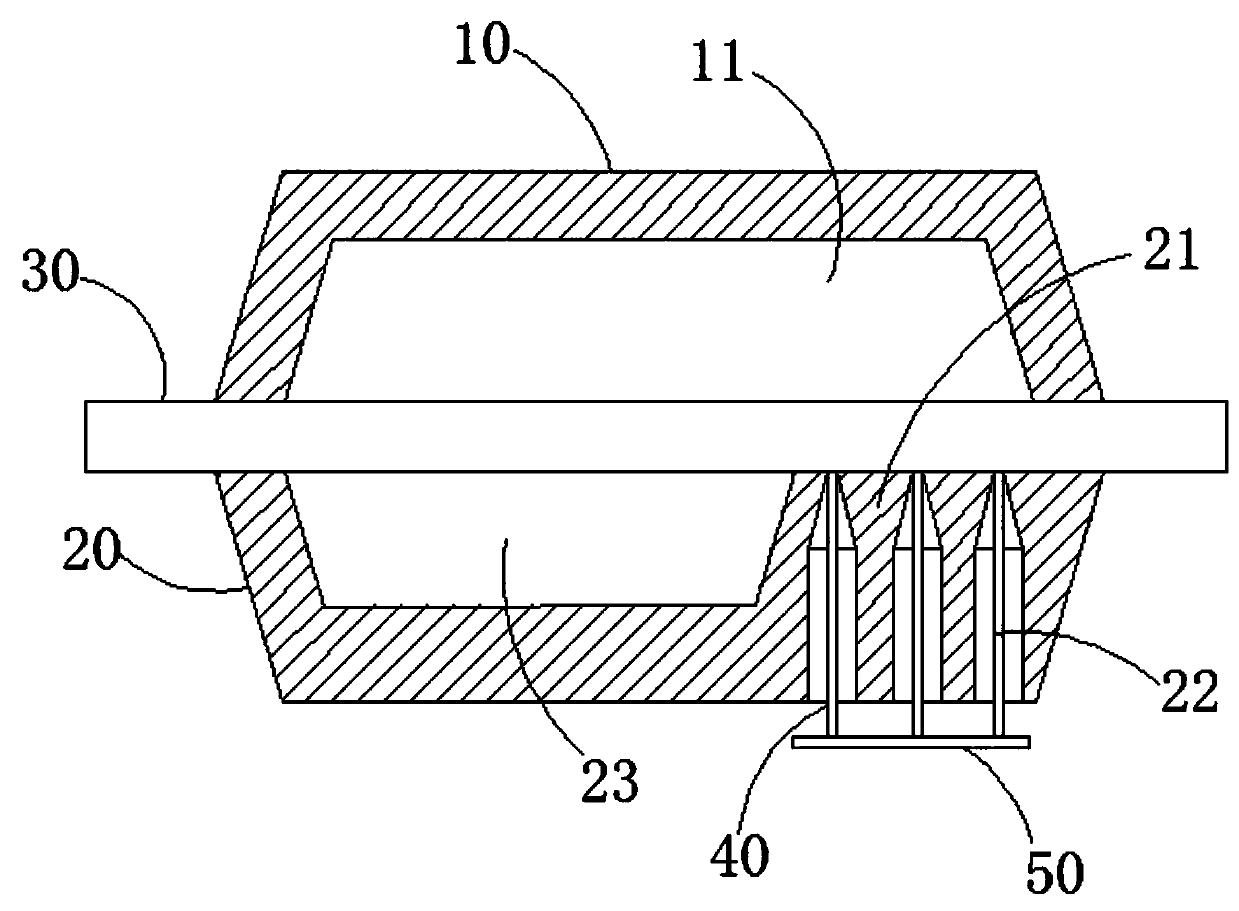

[0050] Such as figure 1 As shown, a double-sided plastic sealing mold is used for one-time plastic sealing of a double-sided PCB board 30, including an upper mold 10 and a matching lower mold 20, and the outer edges of the upper mold 10 and the lower mold 20 are pressed together, and the upper mold 10 and the lower mold 20 are pressed together. The mold 10 is provided with a first groove 11, and the lower mold 20 is provided with a second groove 23. When the upper mold 10 and the lower mold 20 are molded together, the first groove 11 and the first surface of the PCB board 30 to be packaged A first cavity is formed between the regions, and a second cavity is formed between the second groove 23 and the region to be packaged on the second surface of the PCB 30 . The contours of the outer edges of the upper mold 10 and the lower mold 20 are consistent to ensure that when the upper mold 10 and the lower mold 20 are closed, the position of the pressed PCB board 30 is corresponding, ...

Embodiment 2

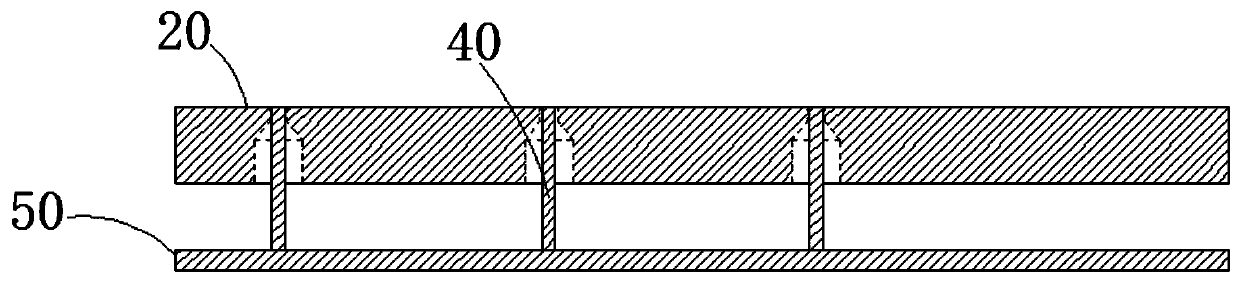

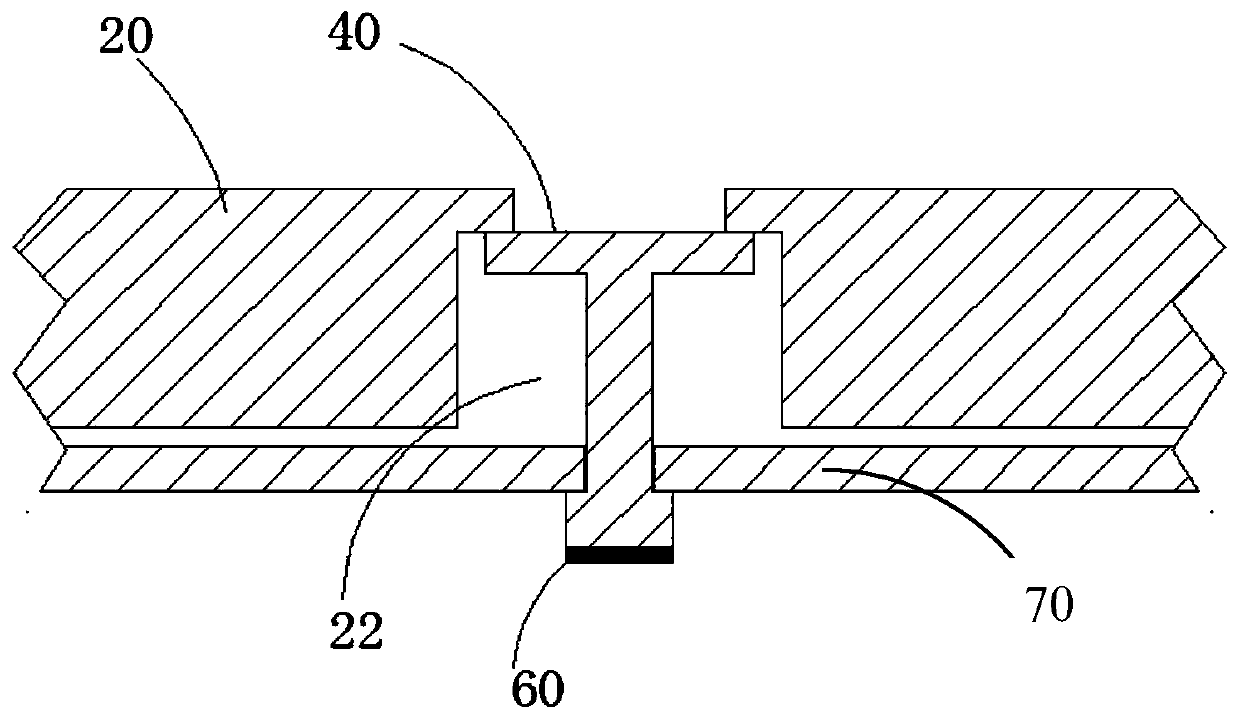

[0059] On the basis of Embodiment 1, in order to solve the problem of excessive suction force of the vacuum hole 22, the vacuum hole 22 can be set in a variable-diameter shape instead of a cylindrical shape with a single hole diameter, and the smallest hole diameter of the vacuum hole 22 is located at the suction part 21 surfaces. Such as figure 1 As shown, the vacuum hole 22 is made up of a first cylindrical section and a connected conical section, the end of the first cylindrical section away from the conical section is flush with the outer surface of the lower die 20, and the first cylindrical section extends upwards to The larger opening end of the tapered section and the smaller opening end of the tapered section are flush with the surface of the suction part 21 . When clearing the mold, the top of the thimble 40 can move along the tapered inner wall of the tapered section to the surface of the suction part 21 to block the vacuum hole 22 . The design of the first cylind...

Embodiment 3

[0061] On the basis of Embodiment 1, the vacuum hole 22 is composed of three sections: comprising a first cylindrical section, a conical section and a second cylindrical section, the first cylindrical section is connected to the smaller opening end of the conical section, and the second cylindrical section is connected to the smaller opening end of the conical section. The two cylindrical sections are connected to the larger open end of the tapered section, so that the tapered section is located between the first cylindrical section and the second cylindrical section, and the aperture of the second cylindrical section is larger than that of the first cylindrical section. aperture. Before plastic sealing, when the top of the thimble 40 is moved below the smaller opening end of the tapered section, the vacuum hole 22 is evacuated. When the top of the thimble 40 moves to the second cylindrical section, the vacuum suction is the largest; when the top of the thimble 40 moves to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com