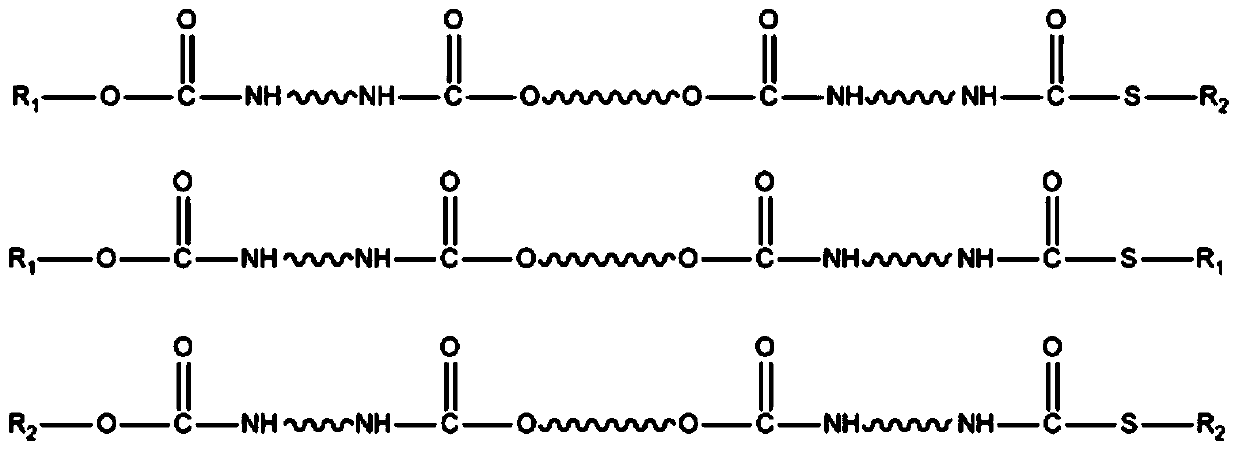

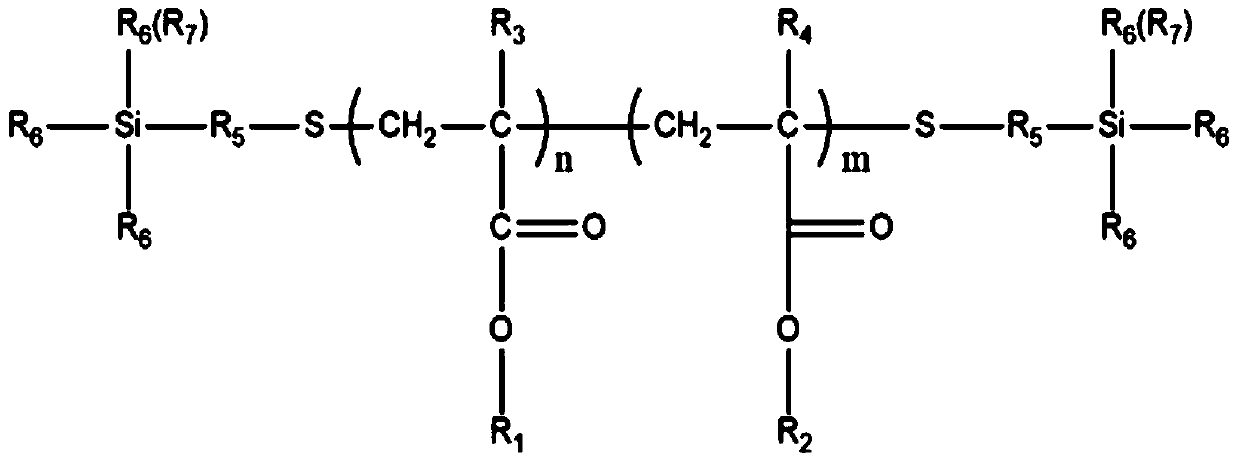

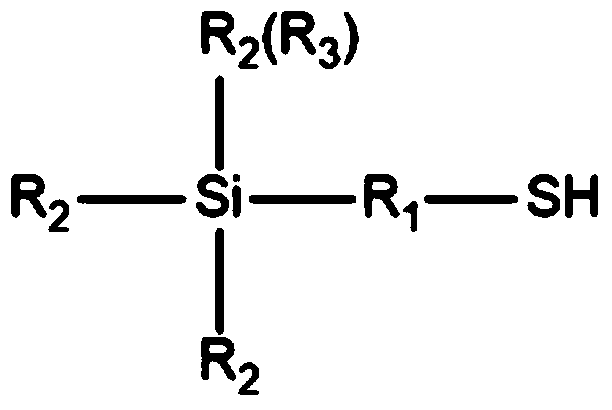

UV-moisture dual-cure liquid optical adhesive and its preparation method and application

A moisture-curing, dual-curing technology, used in adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of wasting manpower and material resources, increasing costs, and complicating the gluing and lamination process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Prepare UV moisture dual-cure liquid optical adhesive according to the ratio in the table below. Accurately weigh 65g UV moisture curing main resin A, 20g tackifying resin A, 8g isobornyl methacrylate, 5g tetrahydrofuran methacrylate, 1g 1-hydroxycyclohexyl phenyl ketone, 1g TEGO Airex 931, 0.1g BYK-431, 0.8g stannous octoate, put all the above-mentioned materials weighed in a planetary vacuum mixer in a thousand-level dust-free workshop, control the temperature at 40-50°C, stir and mix evenly, and pass the obtained rubber material through Filtration and defoaming, the finished product of UV moisture dual-curing liquid optical adhesive can be obtained.

[0061]

Embodiment 2

[0062] Example 2: Prepare UV moisture dual-cure liquid optical adhesive according to the ratio in the table below. Its preparation method is identical with embodiment 1.

[0063]

Embodiment 3

[0064] Example 3: Prepare UV moisture dual-cure liquid optical adhesive according to the ratio in the table below. Its preparation method is identical with embodiment 1.

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com