Environment-friendly nail-free glue for construction and preparation method thereof

A nail-free adhesive and construction technology, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, non-polymer adhesive additive, etc., to achieve good aging resistance, convenient sizing and storage stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

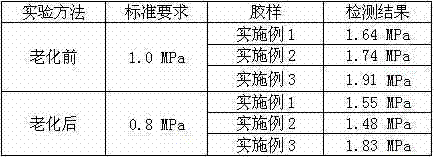

Examples

Embodiment 1

[0034] An environmentally friendly building nail-free glue, its components and specific proportions constitute:

[0035] Polyvinyl acetate 105.0g;

[0036] Methyl acetate 105.0g;

[0037] Ground calcium carbonate 75.0g

[0038] Dioctyl phthalate 5.3g;

[0039] Coupling agent KH-550 3.3g;

[0040] Precipitated silica 24.8g.

[0041] The preparation steps of the above-mentioned polyvinyl acetate type environmental protection building nail-free glue are as follows:

[0042] a. Put methyl acetate into the high-speed stirrer and start the stirrer;

[0043] b. Add polyvinyl acetate and stir for 2.5 hours until each material dissolves into a transparent and uniform liquid;

[0044] c. Add plasticizer and coupling agent KH-550 and stir for 15 minutes until uniform;

[0045] d. Slowly add heavy calcium carbonate and stir for 1 hour to obtain a uniform flowable slurry mixture;

[0046] e. Add precipitated silica, and stir evenly to prepare environmentally friendly building nail-...

Embodiment 2

[0048] An environmentally friendly building nail-free glue, its components and specific proportions constitute:

[0049] Polyvinyl acetate 120.0g;

[0050] Methanol 60.0g;

[0051] Ethyl acetate 60.0g;

[0052] Kaolin 120.0g

[0053] Plasticizer Benzoflex 988 3.6g;

[0054] Silok 778 1.0g

[0055] Coupling agent KH-570 4.0g;

[0056] Fumed silica 8.0g;

[0057] Inorganic bentonite 20.0g.

[0058] The preparation steps of the above-mentioned polyvinyl acetate type environmental protection building nail-free glue are as follows:

[0059] a. Put methanol and ethyl acetate into the high-speed stirrer and start the stirrer;

[0060] b. Add polyvinyl acetate and stir for 2 hours until each material dissolves into a transparent and uniform liquid;

[0061] c. Add plasticizer, dispersant and coupling agent KH-570 and stir for 15 minutes until uniform;

[0062] d. Slowly add kaolin and stir for 1.5 hours to obtain a uniform flowable slurry mixture;

[0063] e. Add inorganic ...

Embodiment 3

[0065] An environmentally friendly building nail-free glue, its components and specific proportions constitute:

[0066] Vinyl acetate-butyl acrylate copolymer 115.0g;

[0067] Methyl acetate 115.0g

[0068] Kaolin 105.0g;

[0069]Coupling agent KH-550 3.3g;

[0070] Organic bentonite 6.0g

[0071] Precipitated silica 6.0 g.

[0072] The preparation steps of the above-mentioned polyvinyl acetate type environmental protection building nail-free glue are as follows:

[0073] a, the ratio of vinyl acetate and butyl acrylate was 9:1 copolymerized in methyl acetate for 12 hours to make vinyl acetate-butyl acrylate copolymer solution;

[0074] B, the vinyl acetate-butyl acrylate copolymer solution is transferred in the high-speed stirrer;

[0075] c. Add coupling agent KH-550 into the mixer and stir for 15 minutes until uniform;

[0076] d. Slowly add kaolin and stir at high speed for 1.5 hours to obtain a uniform flowable slurry mixture;

[0077] e. Add organic bentonite an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com