Concrete anti-segregation water reducing agent and preparation method thereof

A water-reducing agent and anti-segregation technology, applied in the field of concrete water-reducing agent, can solve the problems of unsatisfactory early strength effect, easy bleeding and hardening of concrete, and achieve improved volume stability, initial fluidity and low fluidity , Enhance the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

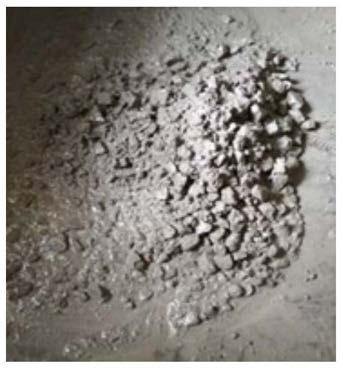

Image

Examples

preparation example Construction

[0076] The second aspect of the present invention provides the preparation method of the concrete anti-segregation water reducer, including the following steps: adding water reducer, air-entraining agent, thickener, retarder, defoamer, and water into the reactor Middle; turn on the stirring tank, stir at a stirring speed of 20-40 rpm for 10-20 minutes, then continue stirring at a stirring speed of 40-60 rpm for 20-40 minutes, then transfer and store for later use.

[0077] In a preferred embodiment, the preparation method of the concrete anti-segregation water reducer includes the following steps: adding water reducer, air-entraining agent, thickener, retarder, defoamer, and water into the reactor Middle; turn on the stirring tank, stir for 20 minutes at a stirring speed of 30 rpm, and then continue to stir for 40 minutes at a stirring speed of 50 rpm, then transfer and store for future use.

Embodiment 1

[0082] Embodiment 1 provides a concrete anti-segregation water reducer, which at least includes the following components in parts by weight: 30 parts of water reducer, 16 parts of air-entraining agent, 2 parts of thickener, 1 part of retarder, disinfectant Foam agent 2 parts.

[0083] The water reducer is a mixture of naphthalenesulfonate formaldehyde condensate water reducer and sulfamate water reducer, with a weight ratio of 1:1; the naphthalenesulfonate formaldehyde condensate water reducer was purchased from Hubei Ai Gold Chemical Co., Ltd.; the sulfamate water reducer was purchased from Guizhou Huangteng Building Materials Co., Ltd.

[0084]The air-entraining agent is a mixture of lignosulfonate and nonylphenol polyoxyethylene ether, with a weight ratio of 1:1.2; the lignosulfonate is sodium lignosulfonate, purchased from Shandong Haoyao New Material Co., Ltd. Co., Ltd.; the nonylphenol polyoxyethylene ether was purchased from Jinan Century Tongda Chemical Co., Ltd.

[...

Embodiment 2

[0090] Example 2 provides a concrete anti-segregation water reducer, which at least includes the following components in parts by weight: 30 parts of water reducer, 16 parts of air-entraining agent, 2 parts of thickener, 1 part of retarder, disinfectant Foam agent 2 parts.

[0091] The water reducer is a mixture of naphthalenesulfonate formaldehyde condensate water reducer and sulfamate water reducer, with a weight ratio of 1:0.5; the naphthalenesulfonate formaldehyde condensate water reducer was purchased from Hubei Ai Gold Chemical Co., Ltd.; the sulfamate water reducer was purchased from Guizhou Huangteng Building Materials Co., Ltd.

[0092] The air-entraining agent is a mixture of lignosulfonate and nonylphenol polyoxyethylene ether, with a weight ratio of 1:0.5; the lignosulfonate is sodium lignosulfonate, purchased from Shandong Haoyao New Material Co., Ltd. Co., Ltd.; the nonylphenol polyoxyethylene ether was purchased from Jinan Century Tongda Chemical Co., Ltd.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com