Environment-friendly and decorative nail-free glue and preparation method thereof

A nail-free, environmentally friendly technology, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., to achieve good storage stability, simple operation process, and convenient glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

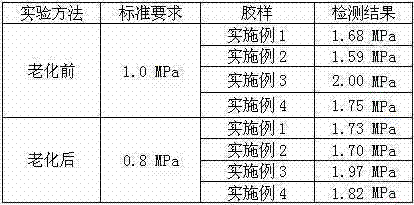

Examples

Embodiment 1

[0031] A kind of environment-friendly decorative nail-free glue The components and specific proportions constitute:

[0032] SBS resin 46.0g;

[0034] Terpene resin 20.0g;

[0035] Poly-alpha-methylstyrene 35.0g;

[0036] 6# solvent oil 83.0g;

[0037] Ethyl acetate 42.8g;

[0038] Ground calcium carbonate 135.0g;

[0039] Fumed silica 10.0g;

[0040] Antioxidant T501 1.9g.

[0041] The concrete steps of preparation method are as follows:

[0042] a. Put 6# solvent oil and ethyl acetate into the high-speed agitator, and start the agitator;

[0043] b. Add SBS resin and rubber, rosin glyceride, terpene resin, and polyα-methylstyrene in sequence, and stir for 4 hours until each material dissolves into a uniform liquid;

[0044] c. Slowly add heavy calcium carbonate, stir for 1 hour to prepare a uniform flowable slurry mixture;

[0045] d. Add fumed silica and antioxidant, and stir evenly to prepare environmentally friendly decorative nai...

Embodiment 2

[0047] A kind of environment-friendly decorative nail-free glue The components and specific proportions constitute:

[0048] SBS rubber 49.0g

[0049] Rosin 18.0g;

[0050] C5 petroleum resin 8.0g;

[0051] C9 petroleum resin 28.0g;

[0052] Terpene resin 18.0g;

[0053] 120# solvent oil 88.0g;

[0054] Methyl acetate 40.8g;

[0055] Kaolin 128.0g;

[0056] Fumed silica 8.0g;

[0057] Antioxidant T501 0.8g.

[0058] The concrete steps of preparation method are as follows:

[0059] a. Put 120# solvent oil and methyl acetate into the high-speed agitator, and start the agitator;

[0060] b. Add SBS resin, rubber, rosin, C5 petroleum resin, C9 petroleum resin, and terpene resin in sequence, and stir for 4 hours until each material dissolves into a uniform liquid;

[0061] c. Slowly add kaolin, stir for 1 hour to prepare a uniform flowable slurry mixture;

[0062] d. Add fumed silica and antioxidant, and stir evenly to prepare environmentally friendly decorative nail-fre...

Embodiment 3

[0064] A kind of environment-friendly decorative nail-free glue The components and specific proportions constitute:

[0065] Neoprene 45.0g;

[0066] C9 petroleum resin 35.0g;

[0068] 6# solvent oil 80.0g;

[0069] Ethyl acetate 15.3g;

[0070] Methyl acetate 17.5g;

[0071]Kaolin 63.0g;

[0073] Precipitated silica 15.0g;

[0074] Antioxidant T501 0.8g.

[0075] The concrete steps of preparation method are as follows:

[0076] a. Put 6# solvent oil, ethyl acetate and methyl acetate into the high-speed stirrer, and start the stirrer;

[0077] b. Add neoprene, carbon nine petroleum resin, and rosin glyceride successively, and stir for 8 hours until each material dissolves into a uniform liquid;

[0078] c. Slowly add kaolin and talcum powder, and stir for 1 hour to obtain a uniform flowable slurry mixture;

[0079] d. Add precipitated silica and antioxidant, and stir evenly to prepare environmentally friendl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com