Heat and cold resisting water-soluble air-drying acrylic resin and preparing method thereof

An acrylic resin, hot water soluble technology, applied in the direction of coating, etc., can solve the problems of insufficient water resistance, insufficient dryness, easy to be stained, etc., and achieve the effect of superior cold and heat resistance, fast drying speed, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

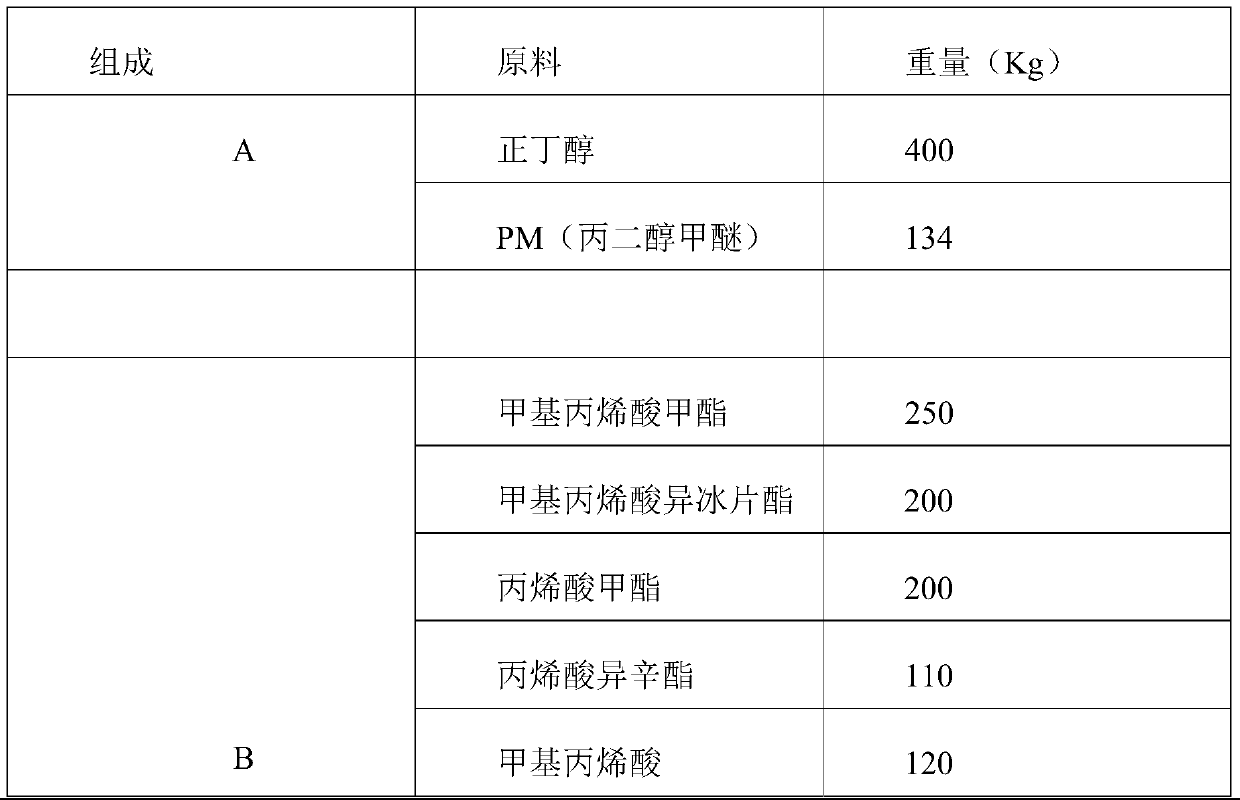

specific Embodiment 1

[0049] A kind of hot and cold water-resistant self-drying type acrylic resin preparation step comprises as follows:

[0050] 1) Put material A into the reactor and heat up to reflux;

[0051] 2) Add material B evenly and at a constant speed, and the common dropping time is 4 hours;

[0052] 3) After the dropwise addition, keep the reflux reaction for 3 hours;

[0053] 4) Add C material, and keep warm for 3.5 hours;

[0054] 5) Remove 402Kg of 60% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0055] 6) Add material E co-solvent and deionized water to dilute, disperse evenly, filter and pack.

[0056] Main technical indicators of a cold and hot water soluble self-drying acrylic resin:

[0057] Appearance: transparent or slightly opalescent viscous liquid;

[0058] Color (Fe-Co colorimetric): ≤2;

[0059] Solid content: 55±2%;

[0060]...

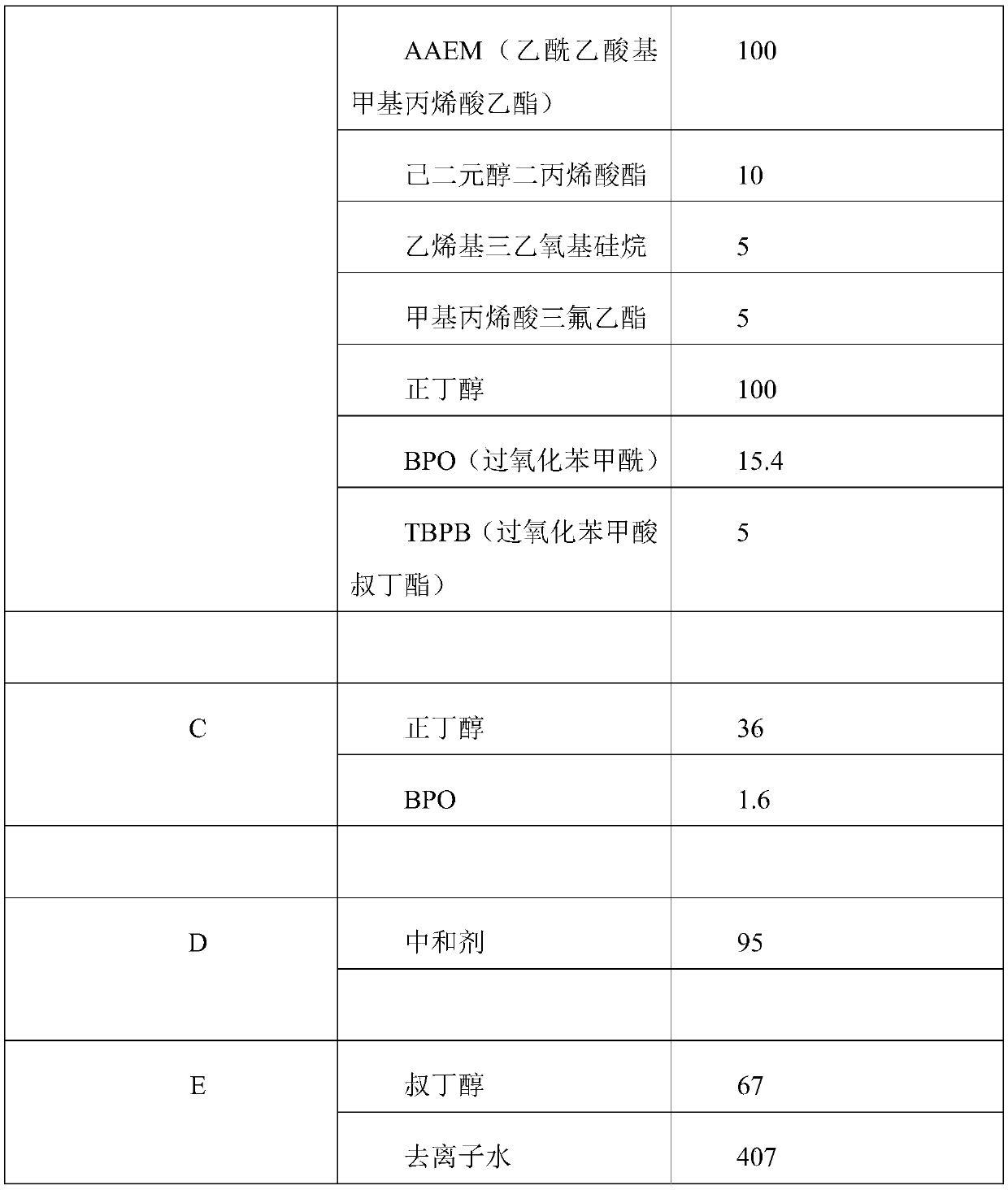

specific Embodiment 2

[0065] A kind of hot and cold water-resistant self-drying type acrylic resin preparation step comprises as follows:

[0066] 1) Put material A into the reactor and heat up to reflux;

[0067] 2) Add material B evenly and at a constant speed, and the common dropping time is 4 hours;

[0068] 3) After the dropwise addition, keep the reflux reaction for 3 hours;

[0069] 4) Add C material, and keep warm for 3.5 hours;

[0070] 5) Remove 365Kg of 55% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0071] 6) Add material E co-solvent and deionized water to dilute, disperse evenly, filter and pack.

[0072] Main technical indicators of a cold and hot water soluble self-drying acrylic resin:

[0073] Appearance: transparent or slightly opalescent viscous liquid;

[0074] Color (Fe-Co colorimetric): ≤2;

[0075] Solid content: 50±2%;

[0076]...

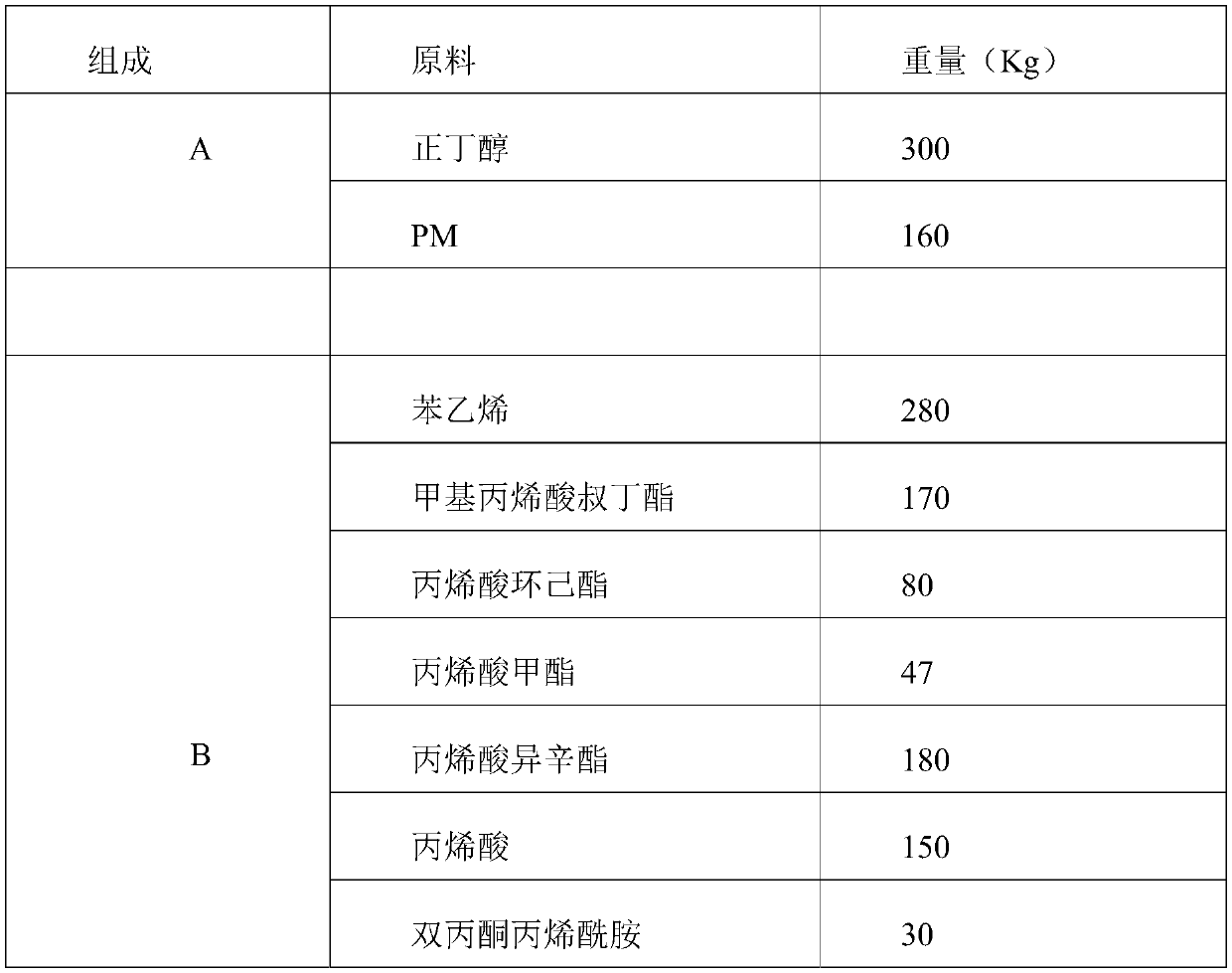

specific Embodiment 3

[0081] A kind of hot and cold water-resistant self-drying type acrylic resin preparation step comprises as follows:

[0082] 1) Put material A into the reactor and heat up to reflux;

[0083] 2) Add material B evenly and at a constant speed, and the common dropping time is 4 hours;

[0084] 3) After the dropwise addition, keep the reflux reaction for 3 hours;

[0085] 4) Add C material, and keep warm for 3.5 hours;

[0086] 5) Remove 435Kg of 65% solvent under reduced pressure and increase temperature, then lower the temperature to below 80°C, add material D neutralizing agent to neutralize evenly, so that the pH value is 7-8;

[0087] 6) Add material E co-solvent and deionized water to dilute, disperse evenly, filter and pack.

[0088] Main technical indicators of a cold and hot water soluble self-drying acrylic resin:

[0089] Appearance: transparent or slightly opalescent viscous liquid;

[0090] Color (Fe-Co colorimetric): ≤2;

[0091] Solid content: 60±2%;

[0092]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com