Patents

Literature

62results about How to "Good cold and heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

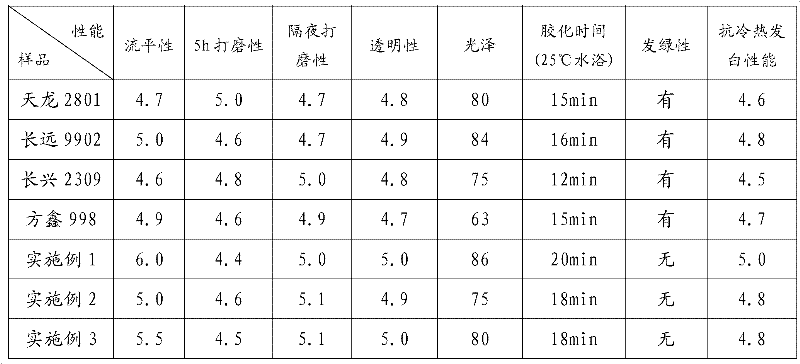

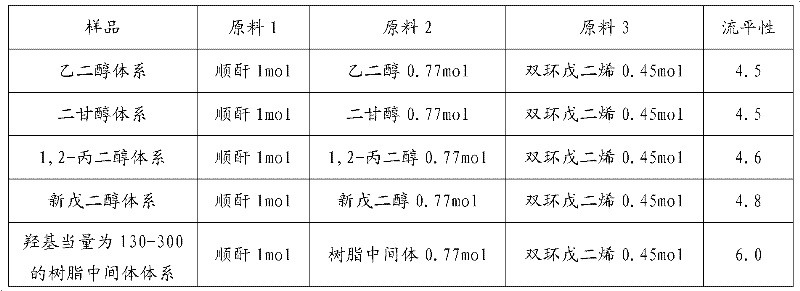

Preparation method of dicyclopentadiene unsaturated polyester resin for high-leveling coatings

ActiveCN102504122AGood wetting and dispersing propertiesReduce surface tensionPolyester coatingsChemistryAddition reaction

The invention discloses a preparation method of dicyclopentadiene unsaturated polyester resin for high-leveling coatings. The method comprises the following steps: A) synthesizing a resin intermediate with the hydroxyl equivalent of 130-300 from fatty acid and polyol which are utilized as raw materials; B) taking dibasic acid (anhydride) and deionized water to perform hydrolysis reaction, then dropwise adding dicyclopentadiene to perform hydrogen ion displacement reaction and diene addition reaction, and then adding dibasic alcohol, the polyol, the resin intermediate prepared in the step A), the dibasic acid or dibasic acid anhydride, an antioxidant and a polymerization inhibitor to perform polycondensation reaction; and C) adding the polymerization inhibitor and styrene crosslinking monomers to dilute, and uniformly mixing so as to get the dicyclopentadiene unsaturated polyester resin for the high-leveling coatings. The dicyclopentadiene unsaturated polyester resin prepared by the method disclosed by the invention is suitable for PE (polyethylene) colored primers, PE transparent primers and other coatings, can bright excellent paint film smooth performance, and is further good in transparency and resistance to cold and hot whitening.

Owner:CARPOLY CHEM GRP

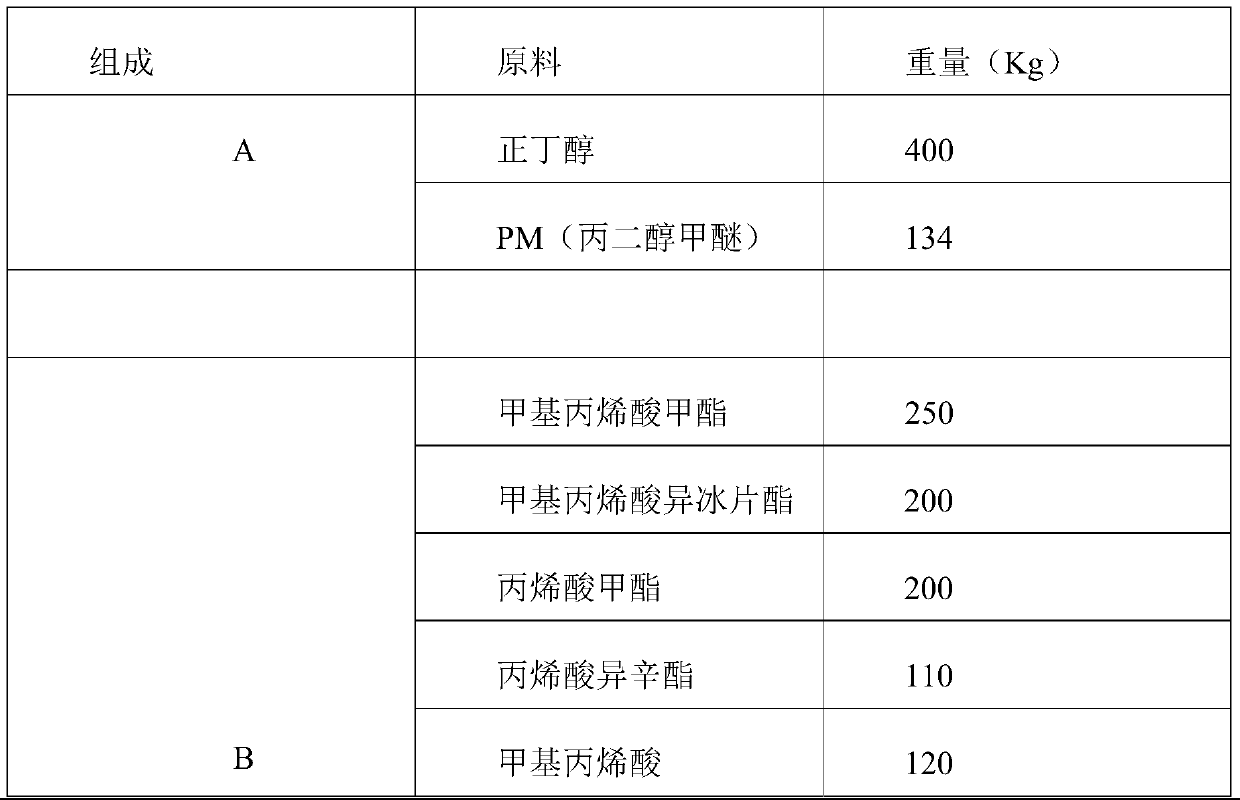

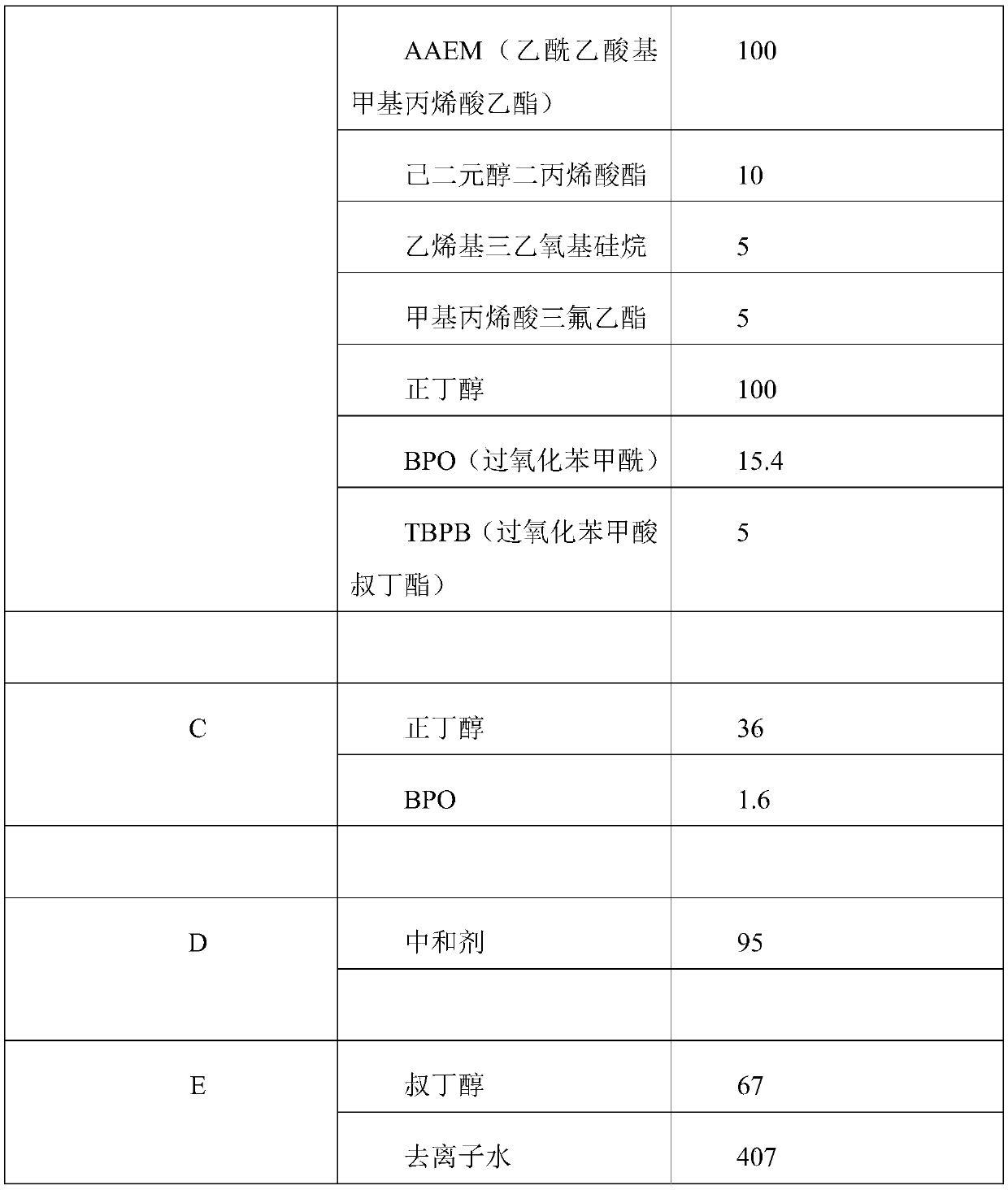

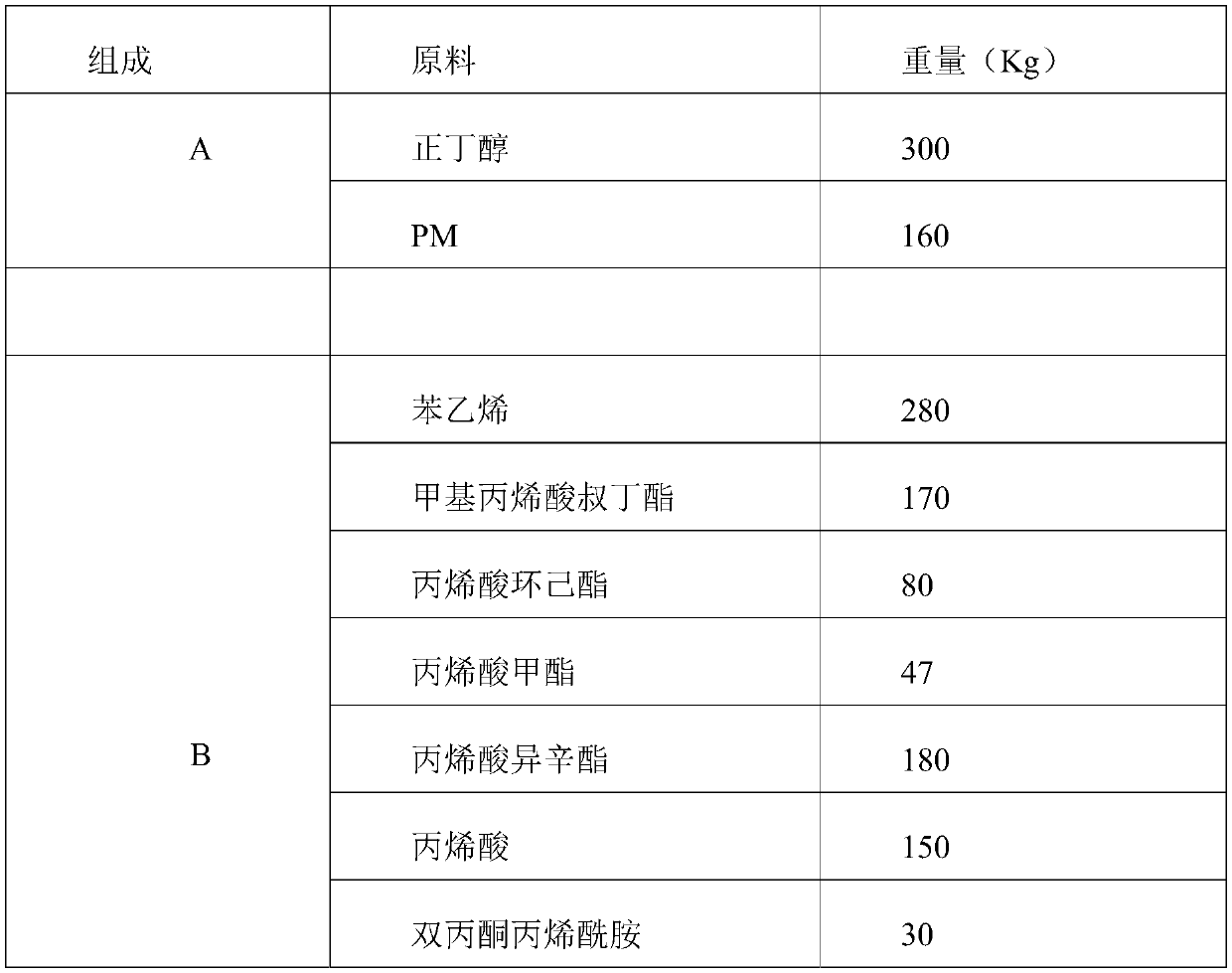

Heat and cold resisting water-soluble air-drying acrylic resin and preparing method thereof

ActiveCN105504137AImprove toughnessGood cold and heat resistanceCoatingsFunctional monomerAcrylic resin

The invention discloses a method for preparing heat and cold resisting water-soluble air-drying acrylic resin. A monometer-phase solution B is prepared from 5-15 wt% of functional monomer, 7-15 wt% of acrylic acid or methacrylic acid, 20-45 wt% of hard monomer, 8-20 wt% of hard tenacity monomer, 15-45 wt% of soft monomer, 0.3-2 wt% of organic siloxane organosilicone monomer, 0.3-2 wt% of fluorine acrylic acid monomer, and 0.5-3 wt% of double-ethylenic-bond monomer, and the total percentage of the monomers is 100%. By the adoption of the method, the heat and cold resisting water-soluble air-drying acrylic resin is provided, and the problems that existing single-component water-soluble acrylic resin paint becomes crispy under the refrigeration condition and becomes tacky and liable to contamination under heating to cause poor membrane surface scratch resistance, dryness is insufficient, and water resistance is low are solved.

Owner:YINGDE BOTE CHEM INDAL

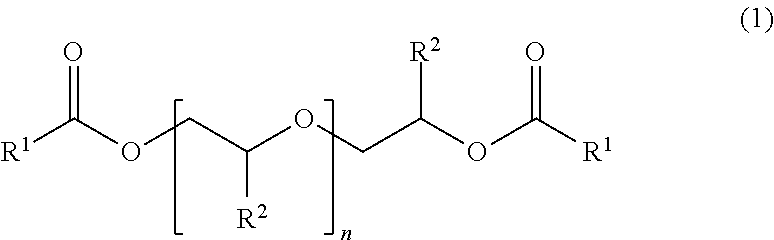

Nitrile group-containing highly saturated copolymer rubber composition and cross-linked rubber

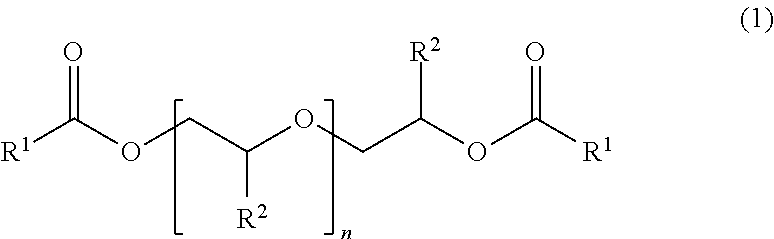

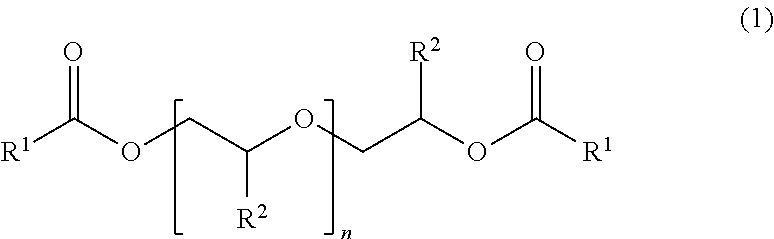

A nitrile group-containing highly saturated copolymer rubber composition includes a nitrile group-containing highly saturated copolymer rubber (A) having α,β-ethylenically unsaturated nitrile monomer units and (meth)acrylic acid ester monomer units and having an iodine value of 120 or less and a polyether ester-based plasticizer (B) having structural unit made of three or more ether compounds which are successively bonded. A nitrile group-containing highly saturated copolymer rubber composition excellent in vulcanization speed and giving cross-linked rubber has excellent heat resistance and cold resistance.

Owner:ZEON CORP

Antibacterial low temperature-resistant heat insulation material

The invention provides an antibacterial low temperature-resistant heat insulation material. The antibacterial low temperature-resistant heat insulation material comprises, by weight, 10-25 parts of LDPE resin, 5-10 parts of modified melamine resin, 20-30 parts of an antibacterial agent, 15- silicone rubber, 20-30 parts of ethylene propylene rubber, 15-25 parts of butadiene rubber, 10-20 parts of styrene butadiene rubber, 3-5 parts of aromatic oil, 1-3 parts of stearic acid, 2-4 parts of a coupling agent, 5-8 parts of a compatibilizer, 10-15 parts of a foaming agent, 5-20 parts of a filler, 1-2 parts of an antioxidant, 1-3 parts of an antioxidant, 3-7 parts of a plasticizer, 5-10 parts of paprika, 5-10 parts of a mildew inhibiotor, 15-25 parts of high-low temperature resistance carbon black, 3-5 parts of nanometer calcium carbonate, 5-15 parts of glass fibers, 5-15 parts of ceramic fibers, 20-35 parts of a flame retardant, 5-10 parts of methylvinyldimethoxysilane and 10-15 parts of kaolin. The antibacterial low temperature-resistant heat insulation material has the advantages of good heat and cold resistance, excellent heat insulation performance, excellent mechanical properties and strong antibacterial property.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

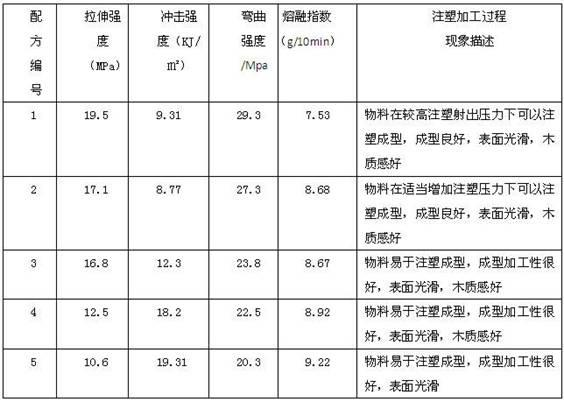

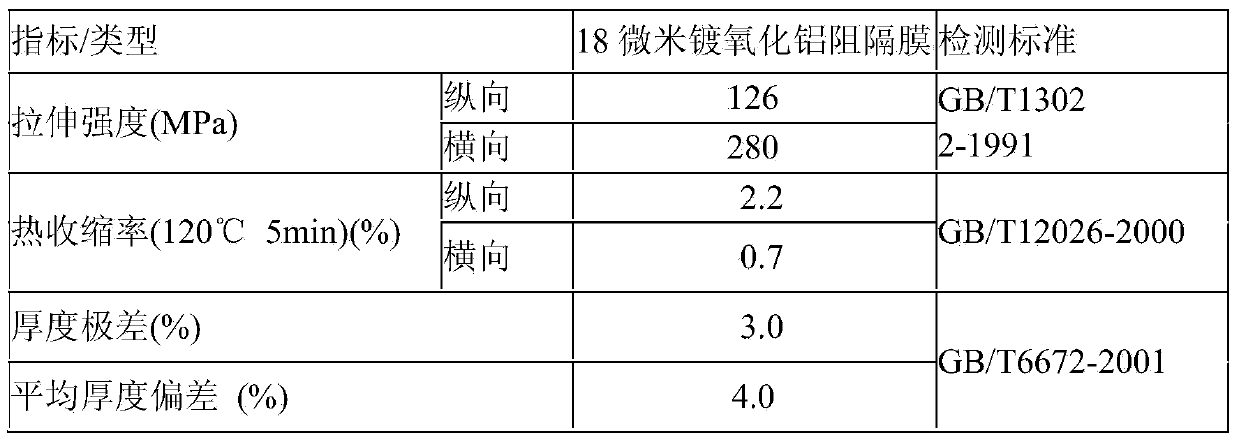

Polyvinyl chloride-based wood plastic composite and preparation method thereof

InactiveCN101974244AImprove physical and chemical propertiesHigh wood flour contentPolyvinyl chlorideMolding grade

The invention provides a polyvinyl chloride (PVC)-based wood plastic composite and a preparation method thereof. The PVC-based wood plastic composite is mixed by the following raw materials by weight percent: 32-51% of PVC, 1-3% of stabilizer, 1-2% of processing additive, 2-3% of impact modifier, 2-3% of lubricant and 40-60% of wood flour. The preparation method comprises the following steps: mixing the raw materials according to the formula ratio, using a conical twin-screw for mixing, cooling and solidifying, and cutting to obtain the finished product. Compared with the common wood plastic material, the prepared molding-grade PVC-based wood plastic composite has the advantages of high wood flour filling volume, good high temperature fluidity and the like and can be directly used for molding production; and the formed wood plastic product has good comprehensive physical-mechanical performance and appearance, strong wood feeling and obvious cost advantage.

Owner:杨大可

Rare earth-copper alloy wire for railway electric power continuous lines, and preparation method thereof

The invention relates to a rare earth-copper alloy wire for railway electric power continuous lines, and a preparation method thereof, and belongs to the technical fields of preparation of copper alloy materials and processing of nonferrous metal wires. The rare earth-copper alloy wire contains rare earth and copper, the content of the rare earth is 0.003-0.05%, the total content of gas elements is less than 20 ppm, and the rare earth is mixed rare earth composed of two or more of lanthanum, cerium, praseodymium, neodymium and yttrium. A high-purity rare earth-copper alloy ingot is prepared through purifying a copper melt by a vacuum induction melting and vacuum electron beam melting duplex technology and the rare earth; and a rare earth-copper alloy wire having certain size specificationsis obtained by cold rolling and cold drawing, and the drawn wire is cleaned and vacuum-annealed. The high-purity rare earth-copper alloy wire produced in the invention has good resistance to wear, cold and heat, has an oxygen content of below 5 ppm, has a conductivity of 98.5-101.8% IACS, and has good application prospect in the railway electric power continuous lines.

Owner:有研科技集团有限公司 +2

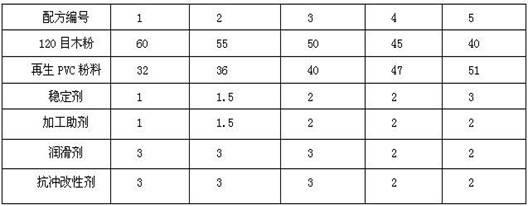

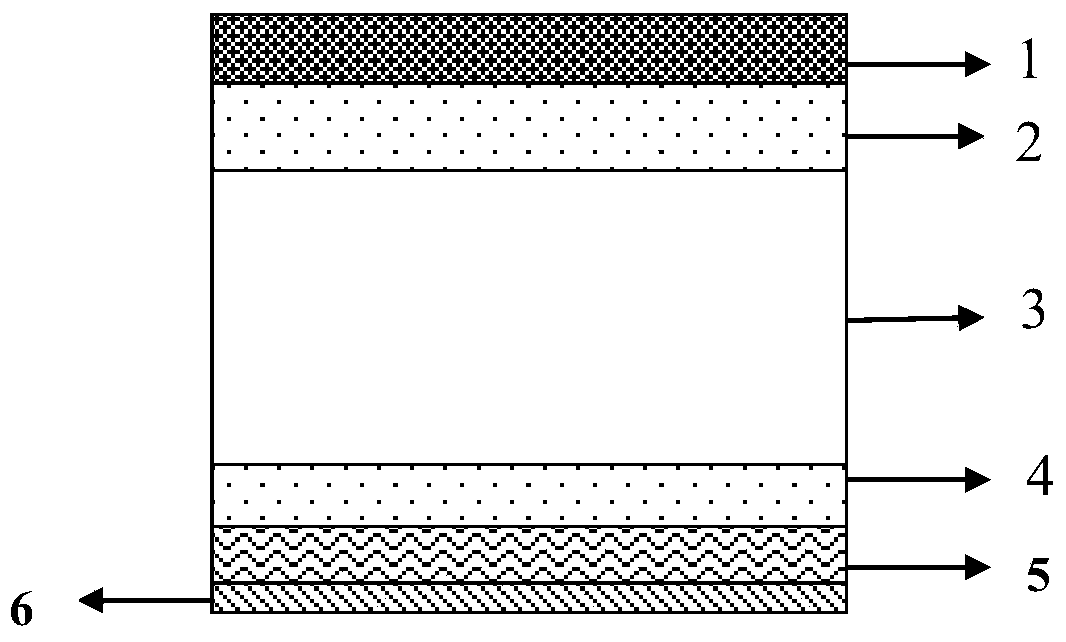

Extra-high obstruction membrane plated with aluminium oxide through coextrusion and biaxial tension and manufacturing method of extra-high obstruction membrane

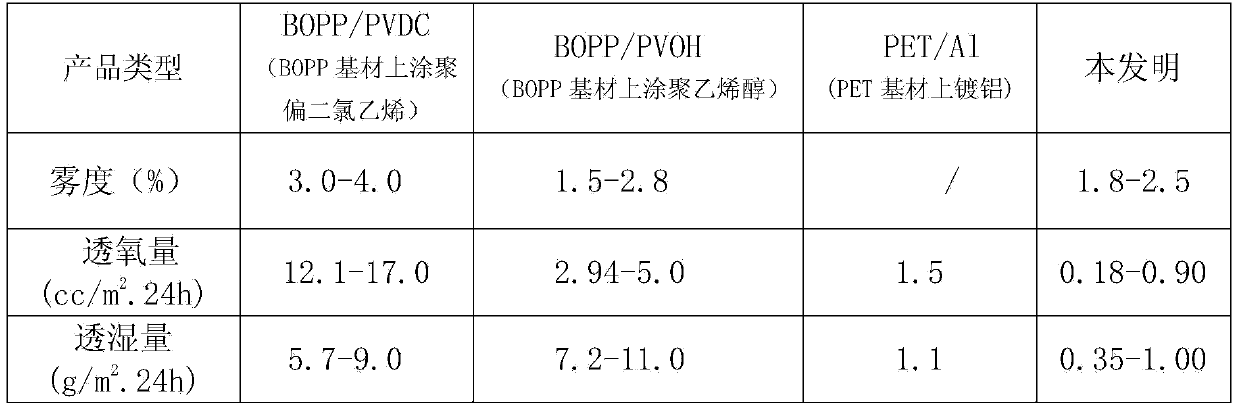

ActiveCN104385748AHigh tensile strengthHigh modulus of elasticityFlexible coversWrappersPolymer sciencePolyamide

The invention relates to an extra-high obstruction membrane plated with aluminium oxide through coextrusion and biaxial tension and a manufacturing method of the extra-high obstruction membrane. The membrane adopts a six-layer structure and comprises an upper layer, an upper secondary layer, a middle layer, a lower secondary layer, a lower layer, and a layer plated with the aluminium oxide. The upper layer is compounded by the following raw materials in percentage by weight: 96-98% of co-polypropylene and 2-4% of an antiblocking agent; the upper secondary layer is compounded by the following raw material in percentage by weight: 100% of homo-polypropylene; the middle layer is compounded by the following raw materials in percentage by weight: 95-97% of the homo-polypropylene and 3-5% of co-ethylene; the lower secondary layer is compounded by the following raw materials in percentage by weight: 75-85% of bonding resin and 15-25% of co-polypropylene resin; the lower layer is compounded by the following raw materials in percentage by weight: 40-50% of high-viscosity amorphous polyamides and 50-60% of polyamides; the thickness of the layer plated with the aluminium oxide is 300-600 angstroms.

Owner:HAINAN SHINER IND

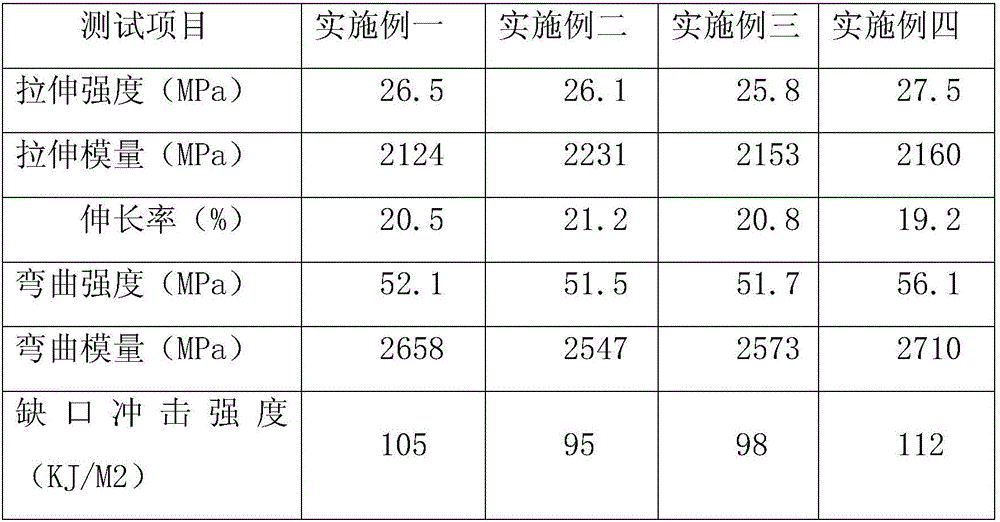

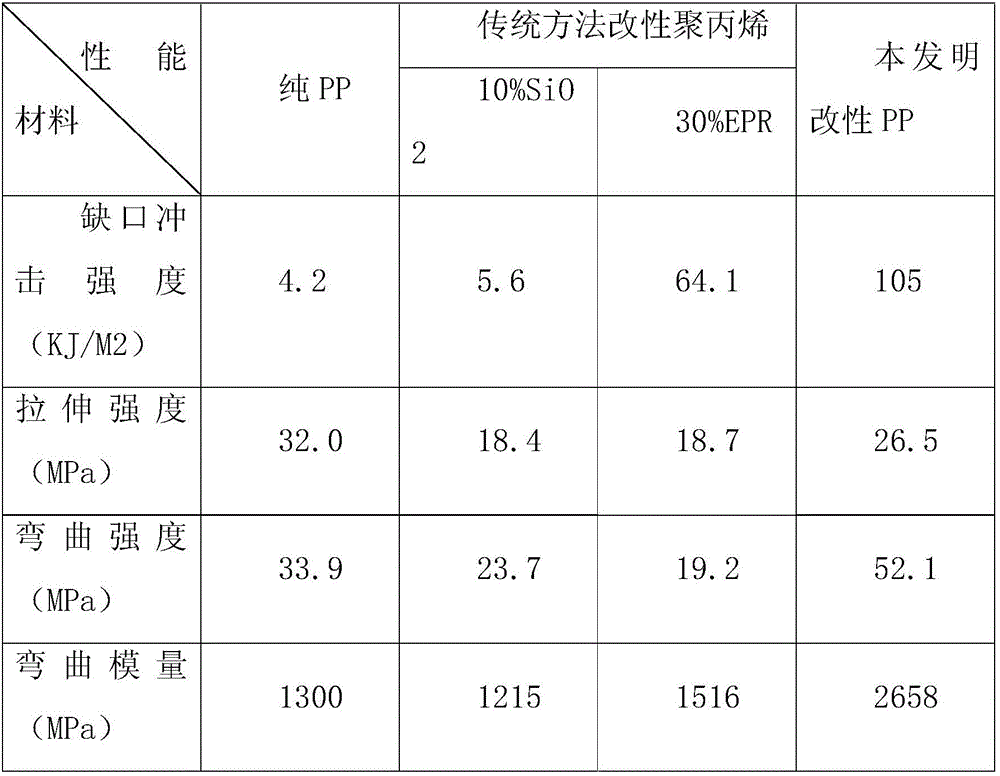

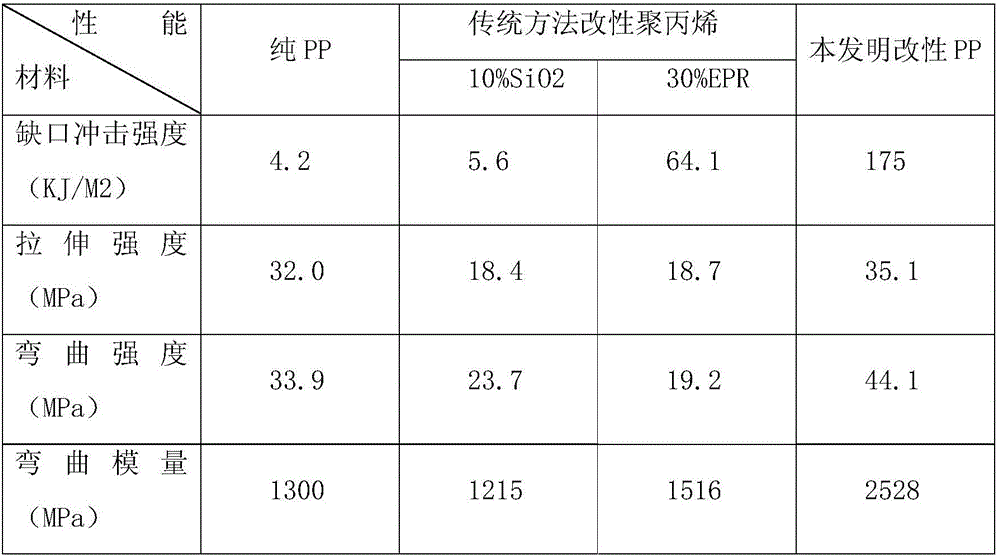

Graphene compounded anti-impact PP (Polypropylene) plastic and preparation method thereof

The invention discloses graphene compounded anti-impact PP (Polypropylene) plastic. The graphene compounded anti-impact PP plastic is prepared from the following components in parts by weight: 70-80 parts of PP, 0.2-0.6 part of an antioxidant, 0.5-2 parts of a lubricant, 0.5-3 parts of a coupling agent and 1-3 parts of graphene oxide. The invention further discloses a preparation method of the graphene compounded anti-impact PP plastic. By adopting the graphene compounded anti-impact PP plastic, the impact strength of the PP plastic is high and the graphene compounded anti-impact PP plastic has a good anti-ageing performance.

Owner:XIAMEN RUNNER IND CORP

Micro arc oxidation composite stain resistant coating and production method thereof

InactiveCN109208054AAvoid disadvantagesPlay the role of crack preventionAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro arc oxidation composite stain resistant coating and a production method thereof. The production method specifically comprises the following steps that 1, a well prepared metal board substrate is mechanically polished, and the corners and the hiding parts are polished through manpower assistance; 2, the metal board substrate polished in the step 1 is placed into a ultrasonic cleaner to be rapidly washed by adding clean water and a sodium hydroxide solution and utilizing ultrasonic waves; 3, the washed metal board substrate in the step 2 is rapidly blown dry in warm air, the greasy stains and rusty spots on the surface of the substrate are removed; and 4, a micro arc oxidation electrolytic solution of potassium hydroxide, sodium sulfate and potassium fluorideis prepared and aged for stand-by application. The production method utilizes a coating machine to spray a layer of silicone fluoride modified coating on the surface of a ceramic layer, the silicone fluoride modified coating has the good anti-adhesion performance, anti-graffiti performance, outdoor durability, cold and hot resistance, stain resistance, anti-scrubbing performance and solvent resistance, and is waterproof and anti-creeping.

Owner:西安庄信新材料科技有限公司

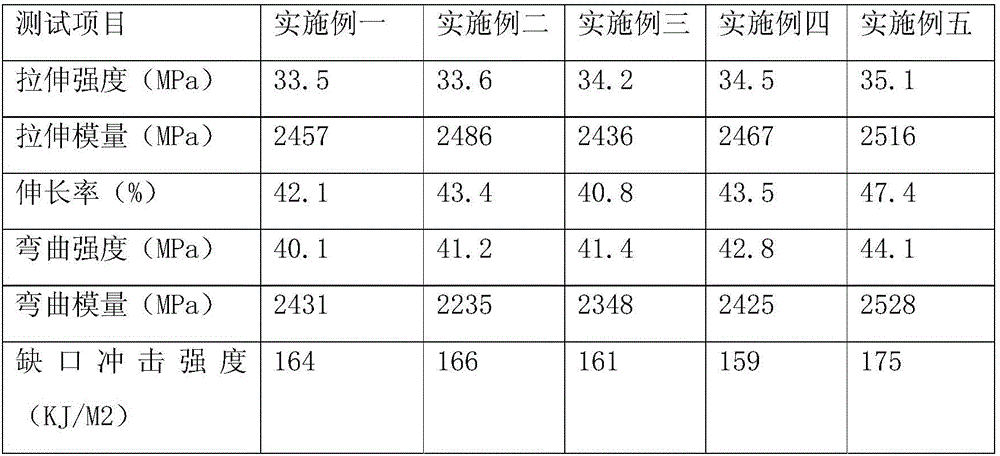

Impact-resistant toughening PP plastic and preparation method thereof

Owner:XIAMEN RUNNER IND CORP

Fluororesin seal ring

InactiveUS20150184749A1Good effectEasy to useEngine sealsOther chemical processesConstant loadAutomatic transmission

A PTFE resin seal ring in which at least one surface of an abutting part that forms a discontinuous part of the seal ring is treated by plasma modification using non-polymerizable gas under pressure conditions of 10 to 500 Pa during plasma irradiation. Since the abutting surfaces of the PTFE resin seal ring are treated with low-pressure plasma, and the state of CF bonds in the surface portion is changed, sticking does not occur in the abutting part even after constant load is applied at a high temperature. Thus, the PTFE resin seal ring of the present invention exhibits excellent effects of ensuring sealing properties under pressure and slidability under ordinary pressure, and is effectively used as a sealing material in, for example, rotation or reciprocation, including hydraulic circuits such as automatic transmissions (A / T) and continuously variable transmissions (CVT) for vehicles.

Owner:NOK CORP

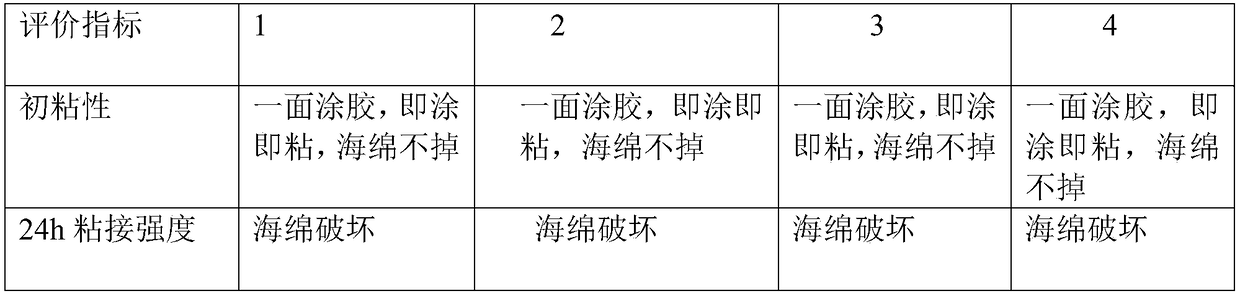

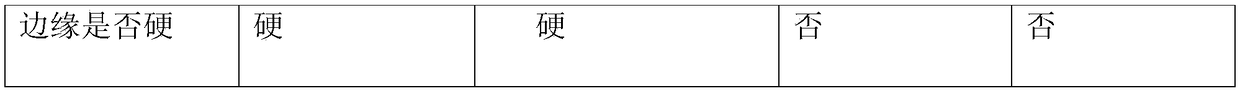

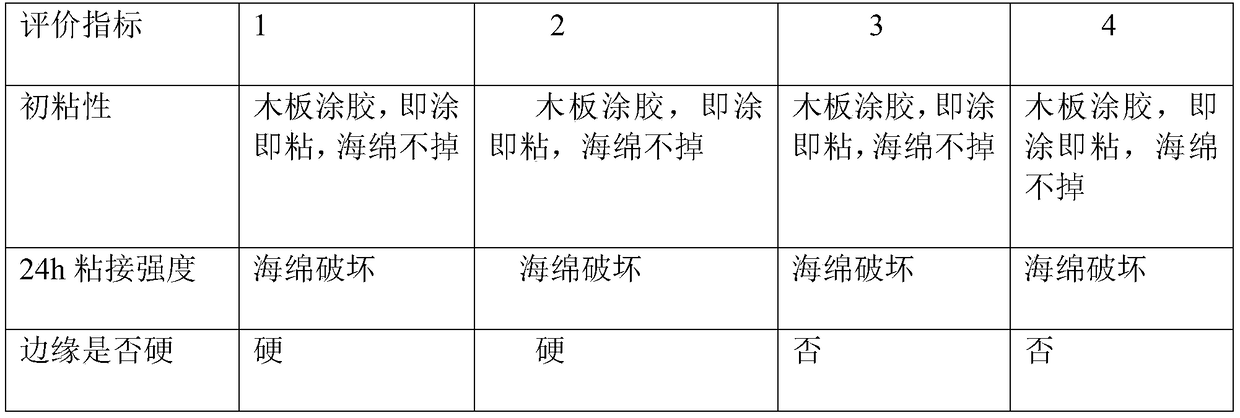

Modified waterborne SBS (styrene-butadiene-styrene) emulsion glue spray and preparation method thereof

InactiveCN109161348ASolving Hard-Edge ProblemsStrength builds fastNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceEmulsion

The invention discloses modified waterborne SBS (styrene-butadiene-styrene) emulsion glue spray. The modified waterborne SBS emulsion glue spray is prepared from components in percentage by mass as follows: 40wt%-70wt% of acrylate modified SBS latex (with solid content being 50wt%), 10wt%-30wt% of styrene-acrylic emulsion (with solid content being 45wt%-60wt%), 5wt%-10wt% of tertiary carbon emulsion, 5wt%-20wt% of tackifying emulsion, 0.2wt%-3wt% of an aqueous coagulant solution, 0.1wt%-0.5wt% of an anti-aging agent, 0.1wt%-1wt% of a stabilizer and 0.2wt%-1wt% of a thickening agent. The modified waterborne SBS emulsion glue spray has the advantages of being excellent in performance, moderate in cost, environmentally friendly, non-toxic and applicable to the glue spray industry, the strength construction is fast, and technological operation is easy.

Owner:GUANGDONG TAIQIANG TECH IND CO LTD

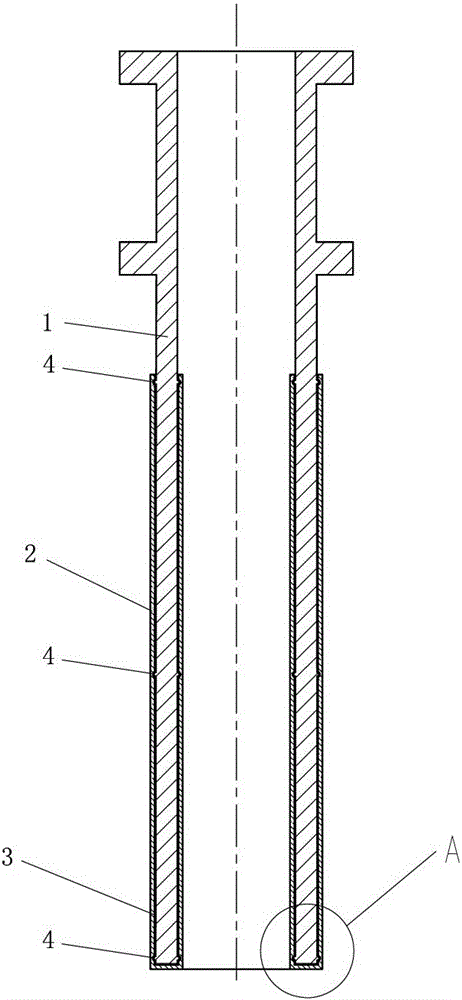

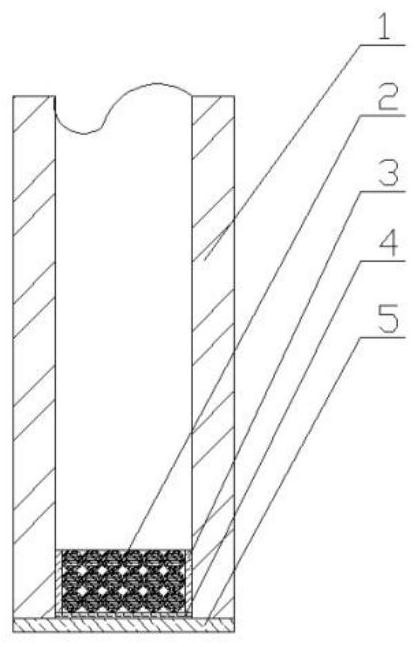

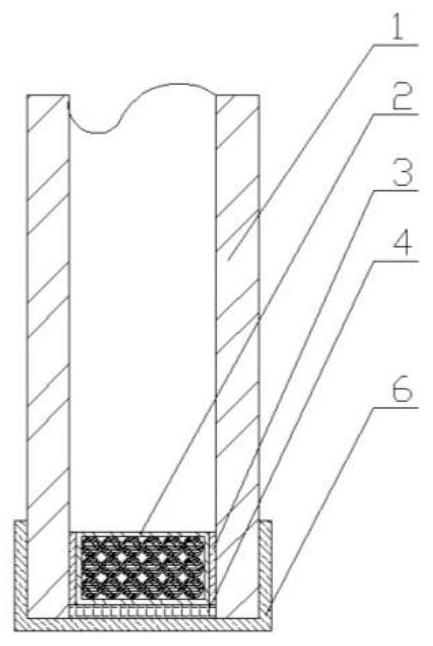

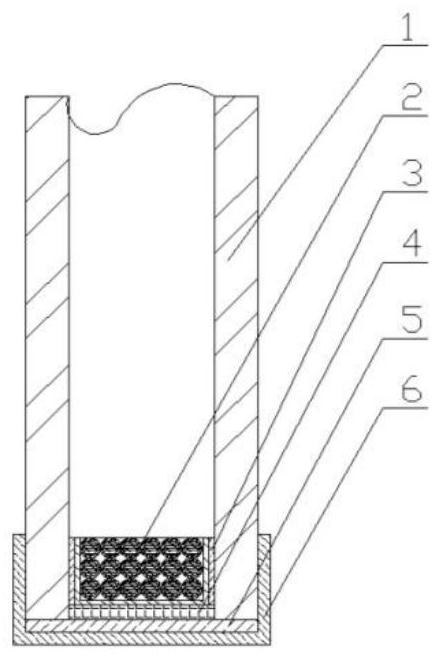

Riser tube and manufacturing method thereof

The invention discloses a riser tube for a low-pressure cast aluminum alloy gearbox and a manufacturing method of the riser tube. The riser tube comprises an iron riser tube body and further comprises a ceramic protection sleeve and refractory cotton transition layers. The iron riser tube body is wrapped with the refractory cotton transition layers. The refractory cotton transition layers are wrapped with the ceramic protection sleeve. The method comprises the steps that the iron riser tube body is made of an ordinary #45 steel material; the refractory cotton transition layers are made of an ordinary fiber refractory cotton material; fixing protruding bosses are manufactured in selected positions of the inner tube wall and the outer tube wall of the iron riser tube body in the axial height direction; the refractory cotton transition layers which are 2 mm+ / -0.5 mm thick are fixed to the inner tube wall and the outer tube wall of the iron riser tube body correspondingly, SiC particles with the purity being 99%+ / -0.2% are fixed to the refractory cotton transition layers, the thickness of the SiC particles is 5 mm+ / -0.5 mm, and the iron riser tube body is placed in a dry and ventilated position to be air-dried; and the air-dried riser tube body is placed into a sintering furnace and subjected to overall sintering, the sintering temperature is about 1390-1410 DEG C, and the riser tube is obtained after roasting. According to the riser tube and the manufacturing method thereof, in the using process, the situation that corrosion occurs and consequently increased iron is generated can be avoided, and manufacturing is easy.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

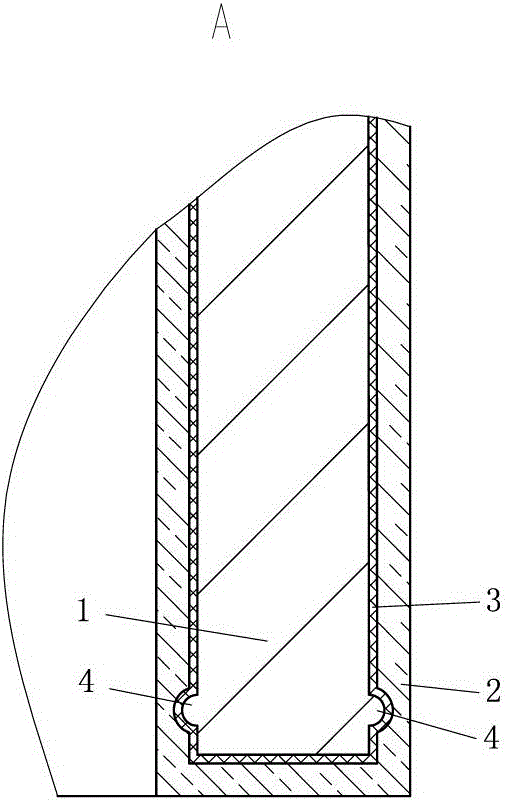

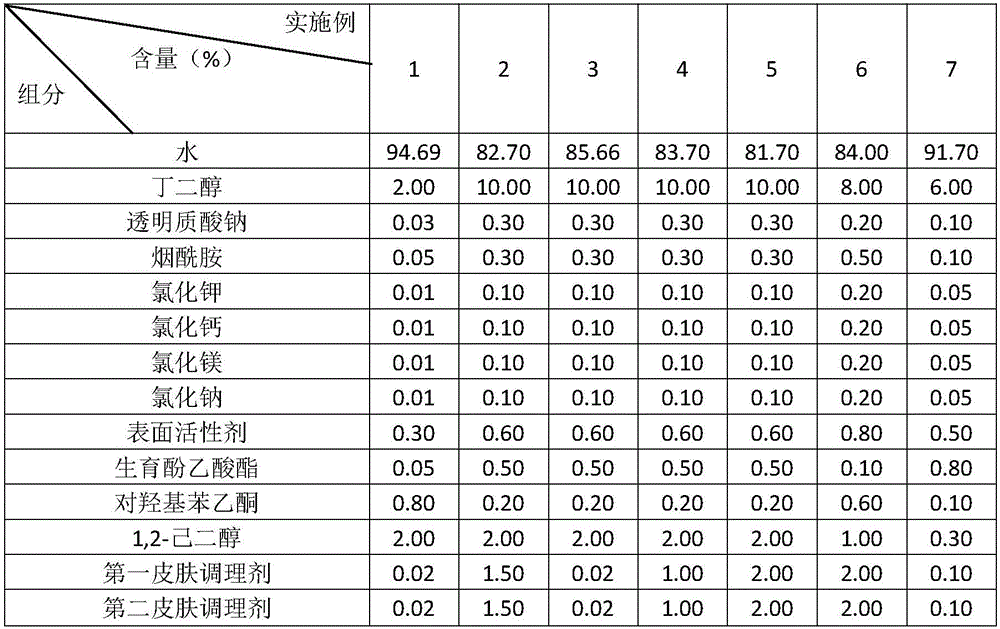

Moisturizing oil-control spray and preparation method thereof

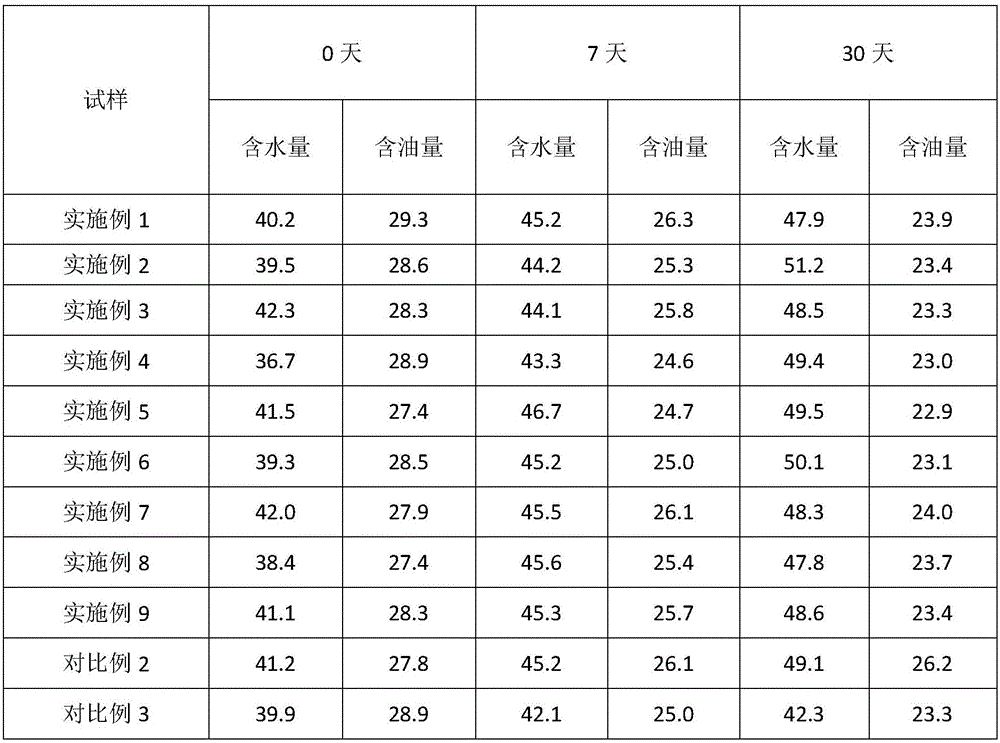

InactiveCN106619310AHigh cold and heat resistanceGood cold and heat resistanceCosmetic preparationsToilet preparationsMedicineCaffeine

The invention discloses moisturizing oil-control spray and a preparation method thereof. The moisturizing oil-control spray comprises the following raw materials by weight percentage: 2.00-10.00% of butanediol, 0.03-0.30% of sodium hyaluronate, 0.05-0.50% of nicotinamide, 0.04-0.80% of a stabilizer, 0.30-0.80% of a surfactant, 0.05-0.80% of tocopheryl acetate, 0.10-0.80% of p-Hydroxyacetophenone, 0.30-2.00% of 1,2-hexanediol, 0.02-2.00% of a first skin conditioner, 0.02-2.00% of a second skin conditioner, and the balance of water. The first skin conditioner comprises cucumis sativus fruit extract of which the weight percentage in the first skin conditioner is 2.00-6.00%; and the second skin conditioner comprises siloxane triol alginate and caffeine of which the weight percentages in the second skin conditioner are 8-10% and 2-6% respectively. The moisturizing oil-control spray is capable of providing the enough moisturizing function for the skin during the oil-control process.

Owner:HANGZHOU FACECARE COSMETICS

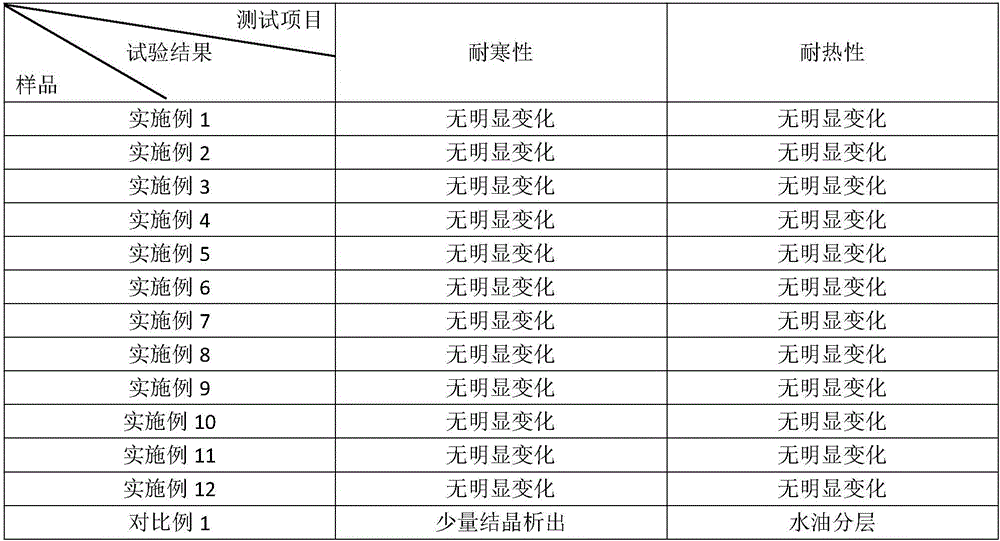

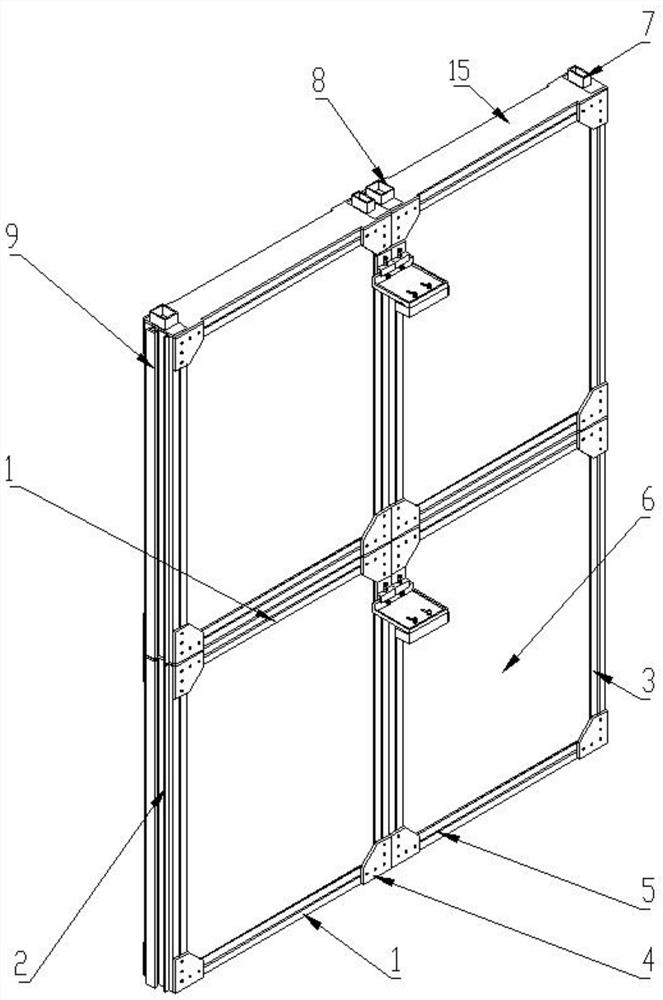

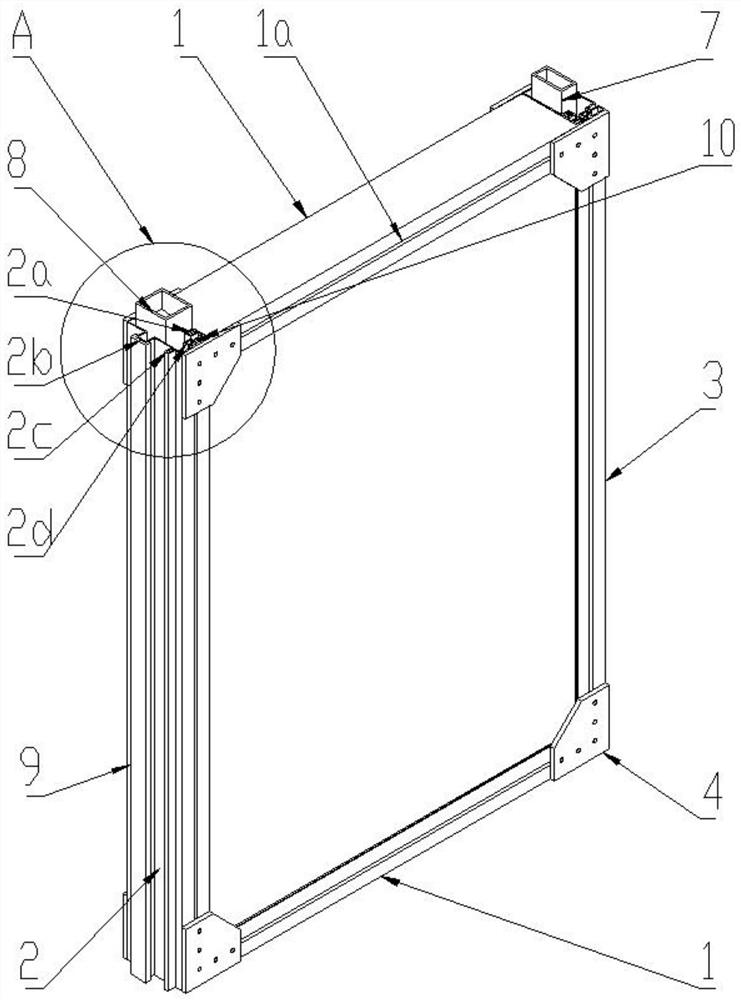

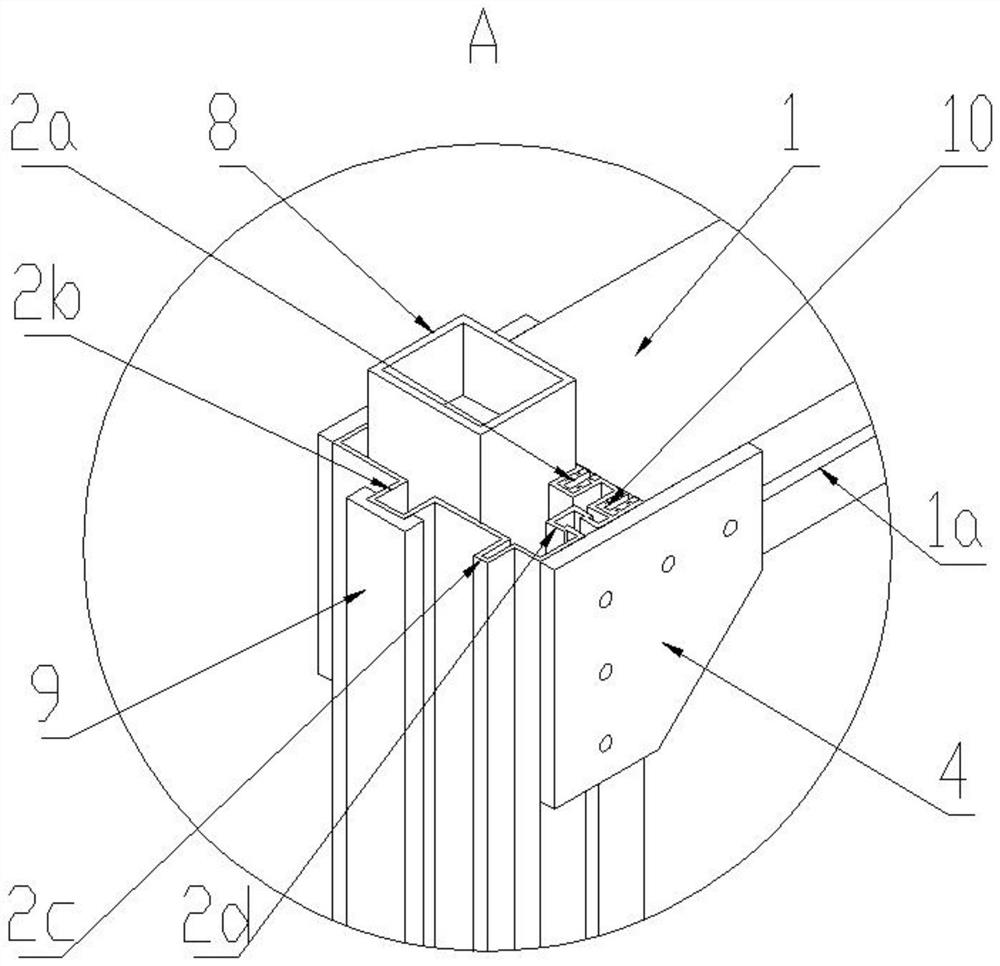

Assembly type unit aluminum curtain wall

ActiveCN111877611AConvenient production and assemblyImprove installation and construction efficiencyWallsHeat proofingEngineeringFire resistance

The invention provides an assembly type unit aluminum curtain wall, belongs to the technical field of decorative wall plates, and aims to solve the problems of low production efficiency, slow construction and mounting and poor performance of an existing aluminum curtain wall. The assembly type unit aluminum curtain wall comprises a stand column I and a stand column II, cross beams and the stand column I are connected through screw joint mounting plates, the cross beams and the stand column II are connected through screw joint mounting plates,an inner aluminum plate and a sound insulation plateare clamped in a sealing rubber strip I and a corresponding sealing rubber strip II correspondingly, and an inserting rod I and a inserting rod II are fixed to the upper ends in the stand column I and the stand column II correspondingly. A heat preservation plate and an outer aluminum plate are connected between clamping blocks in a clamped mode, an inserting protruding block is inserted into anadjacent inserting sealing groove, a sealing waterproof rubber strip is arranged between the inserting protruding block I and the inserting sealing groove, and an adjusting assembly is arranged on thestand column I and the stand columns II which are adjacent. The production efficiency is high, the unit type assembling frame can be formed through rapid assembling, and the construction adjusting and mounting efficiency is high. The assembly type unit aluminum curtain wall has the properties of heat resistance, fire resistance, flame retardance, sound insulation and heat preservation, and is good in sealing performance and waterproof performance after being mounted.

Owner:安徽鑫翊新材料有限公司

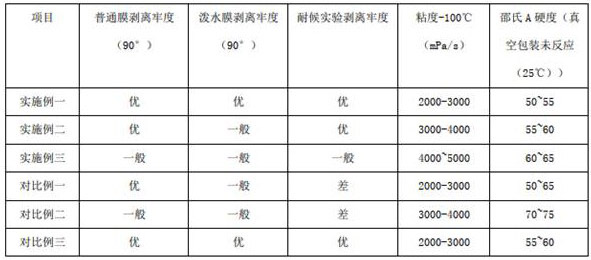

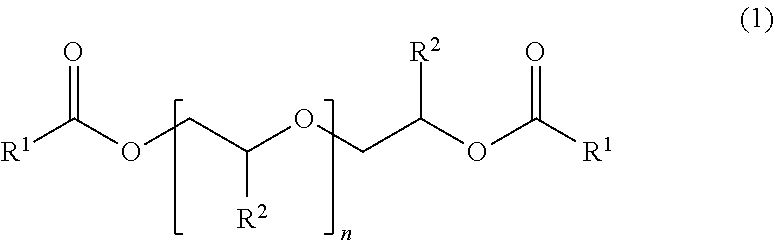

Hot-melt reaction type polyurethane adhesive for compounding electronic nylon film

InactiveCN112143435AGood compatibilityGood permeabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPropanediolAdipic acid

The invention discloses a hot-melt reaction type polyurethane adhesive for compounding an electronic nylon film, and relates to the field of polyurethane adhesives. The hot-melt reaction type polyurethane adhesive comprises the following components in parts by mass: 23-27 parts of irregular reticular polyester polyol; 53-57 parts of polyether polyol; 44-48 parts of isocyanate; and 1-1.5 parts of asilane coupling agent, wherein the irregular reticular polyester polyol is formed by polymerization, esterification and polycondensation of 1,4-butanediol, 2-methyl propylene glycol, neopentyl glycoland adipic acid. By changing the molecular structure of polyurethane, the invention provides a polyurethane adhesive material which has favorable permeability and adhesive force for nylon materials,especially nylon films subjected to water-repellent agent treatment on the surfaces.

Owner:烟台斯普瑞电子材料有限公司

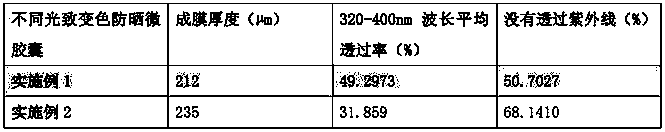

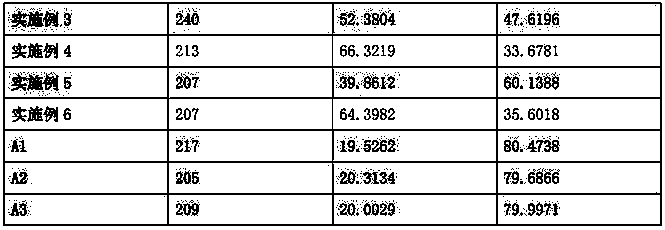

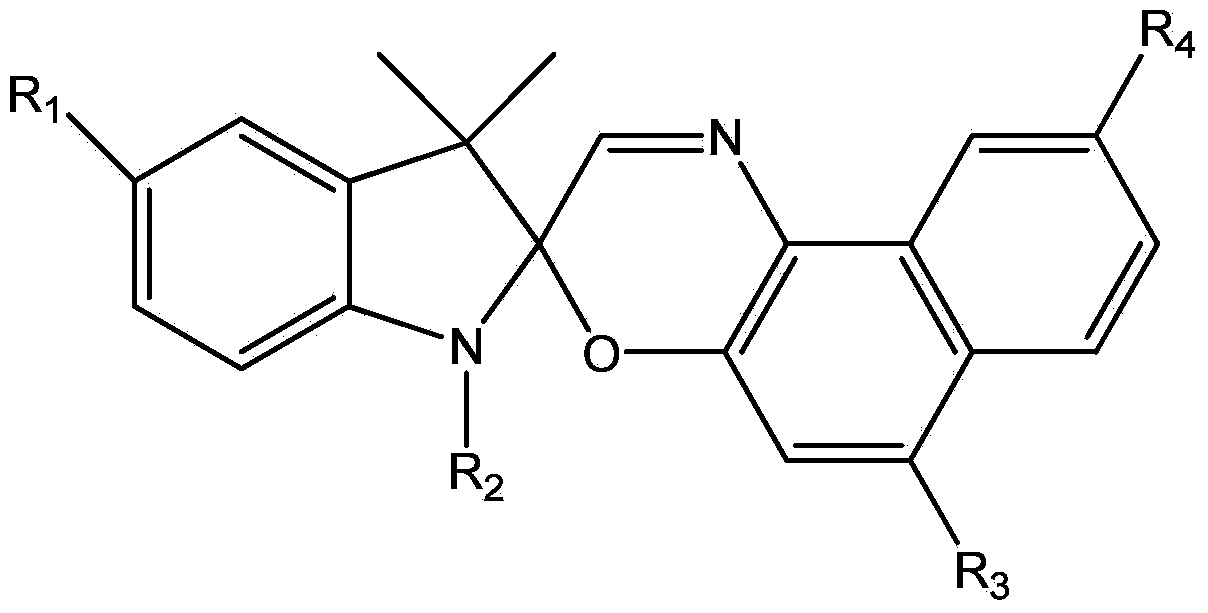

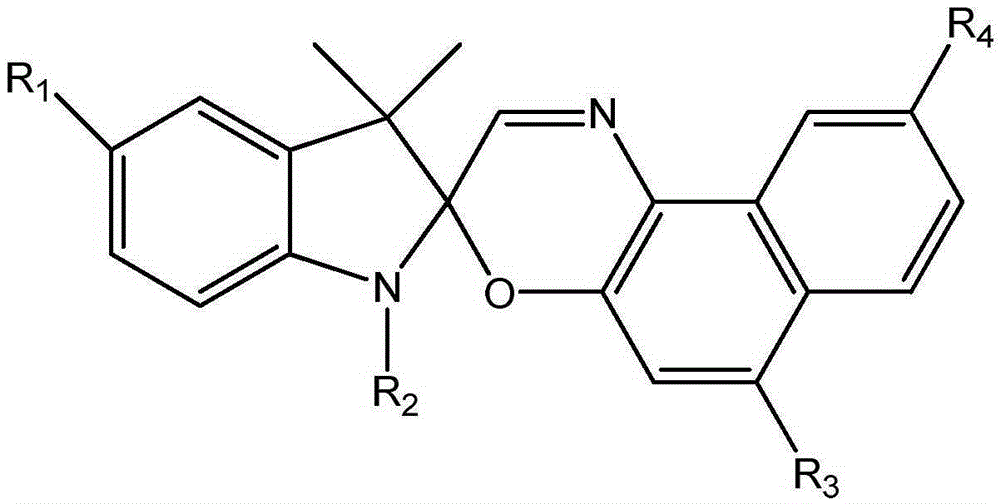

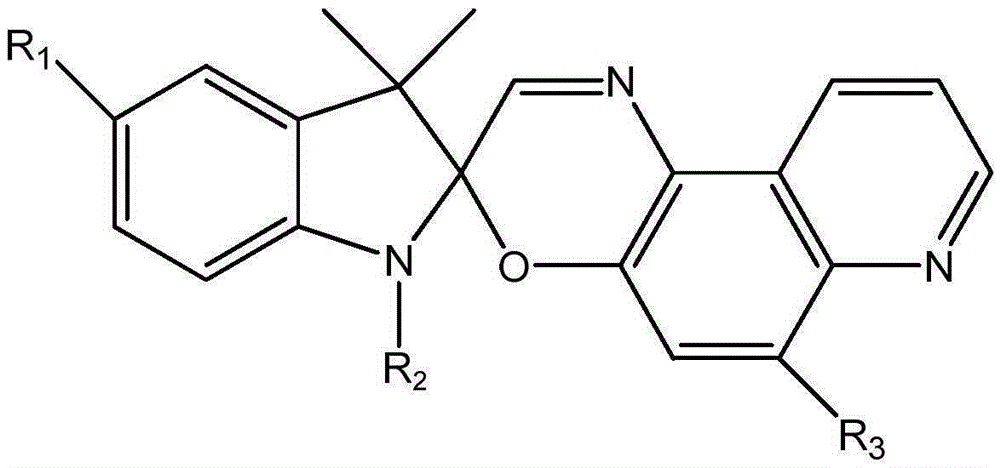

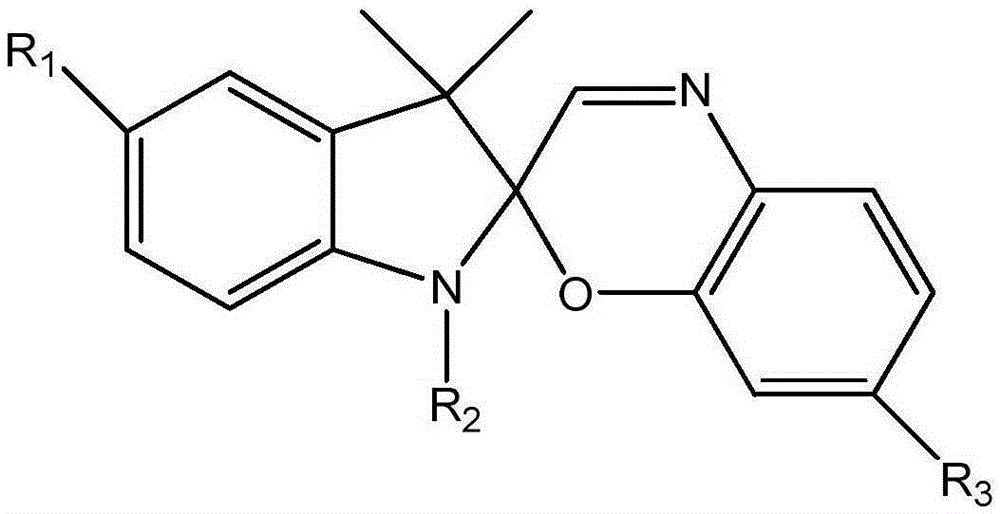

Human body surface coating object containing photochromic sunblock particles

ActiveCN103816056AImproves UV protectionImprove performanceCosmetic preparationsMake-upUltraviolet aUltraviolet lights

The invention provides a photochromic sunblock particle, a human body surface coating object containing photochromic sunblock particles, and application of the coating object in skin sunblock, body painting and a field hidden material. A photochromic material is added into the human body surface coating object and serves as an ultraviolet absorber, the absorption wavelength is between 280 nm and 400 nm and is just in the wavelength range of UVA (ultraviolet a) and UVB (ultraviolet b) radiating to the ground, the absorption efficiency is high, and the ultraviolet protection effect is improved; the photochromic material is stable in performance, long in service life and good in hot and cold resistance, and the fatigue endurance can reach more than 10,000 times; the surface coating object can be changed into various beautiful and bright colors while absorbing ultraviolet light, can change the colors when applied to a human body and irradiated under sunshine, and can be used for body painting, the field hidden material and the like due to the characteristic; and besides, the ultraviolet intensity of sunlight can be evaluated through observation of the color change condition and the color degree, and a user can be reminded of certain ultraviolet protection.

Owner:TIANJIN UVOS TECH CO LTD

Hollow glass with edge sealed by PUR glue and manufacturing method thereof

PendingCN112983204AExtended service lifeImprove initial tackClimate change adaptationWindows/door improvementMolecular sieveMoisture absorption

The invention belongs to the technical field of production of hollow glass, and discloses hollow glass with the edge sealed by PUR glue and a manufacturing method thereof. The hollow glass with the edge sealed by the PUR glue comprises glass, spacing bars, a bonding seal between the glass and the spacing bars and a bonding seal on the periphery of the glass, wherein the bonding seal between the glass and the spacing bars and the bonding seal on the periphery of the glass adopt PUR glue, and the bonding force and the sealing performance are improved by utilizing the chemical reaction between the PUR glue and water adsorbed on the surfaces of the glass and the spacing bars, so that the service life of the hollow glass is prolonged; small-specification hollow glass with a large glue proportion is used, moisture in the hollow cavity is absorbed by utilizing a moisture absorption effect generated by a wet reaction curing mechanism of the PUR glue, and no molecular sieve is arranged in the spacing bars; and large-specification hollow glass with a small glue proportion is used, molecular sieves are arranged in spacing bars, and preferably, the molecular sieves with a slow absorption function are adopted. The method is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality.

Owner:温州前瞻玻璃科技有限公司

Gel gent of Chiense forest frog bactericidal peptide and its preparation process

ActiveCN100333789CStir wellGood treatment effectPeptide/protein ingredientsAntisepticsDiseaseCarboxymethyl cellulose

A tree frog's antibacterial peptide gel for treating the dermatopathy caused by aeruginose pseudomonads and the infection of burn and scald is prepared from antibacterial peptide for tree frog, carboxymethyl cellulose sodium glycerine, sodium dodecyl sulfonate, ethylester of nipagin and water through preparing transparent gel matrix and adding antibacterial peptide of tree frog.

Owner:TONGHUA KANGYUAN BIOLOGICAL TECH

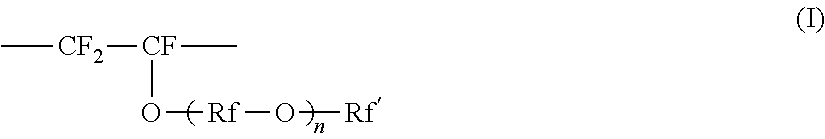

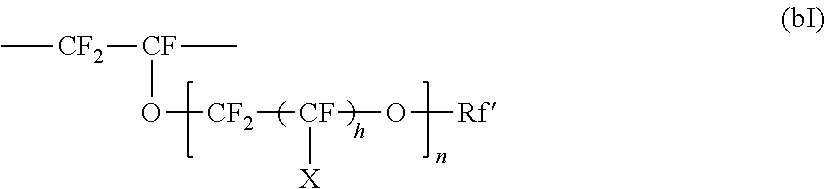

Perfluoroelastomer composition

ActiveUS20110207890A1Low glass transition temperatureExcellent heat resistance and cold resistanceNitrileTetrafluoroethylene

There is provided a perfluoroelastomer composition having a low glass transition temperature and excellent cold resistance and heat resistance and comprising a perfluoroelastomer comprising a tetrafluoroethylene unit (a), a perfluoro vinyl ether unit (b) and a cure site unit (c) having nitrile group, carboxyl group and / or alkoxycarbonyl group as a cure site, wherein the perfluoro vinyl ether unit (b) is contained in an amount of 8 to 23% by mole in the perfluoroelastomer.

Owner:DAIKIN IND LTD

Silicon refractory glass thermochemical moulded brick and its manufacturing method

InactiveCN1579995ASmall coefficient of thermal expansionGood cold and heat resistanceGlass pressing apparatusCeramic shaping apparatusDistortionIron oxide

The invention relates to kiesel thermification swage brick. Its components are as follows: diatomite whose silicon content is over 85 percent: 93-99.2 percent, agglomerate material of diatomite: 0-5.8 percent and berlin red: 0.8-1.2 percent. Graininess of each component is over 300 items. The invention follows nether steps: feed preparation, ball mill, mould preparation, pouring, demouding, drying and agglomeration. The swage brick has merits of high temperature resistance, light quality, tenuity, softness, high intensity, little coefficient of thermal expansion, stability and etc. It can meet different requirements by means of rubbing, incision and etc. It can be widely used in glass making, glass artwork and other industries. The produced eyeglass has no motting, blue edge and distortion. Its distortion rate is less than 7 percent, which can meet quality requirement of eyeglass mould. Being able to use under 900deg.C, it is an advanced thermification mould material to produce eyeglass.

Owner:刘玉华

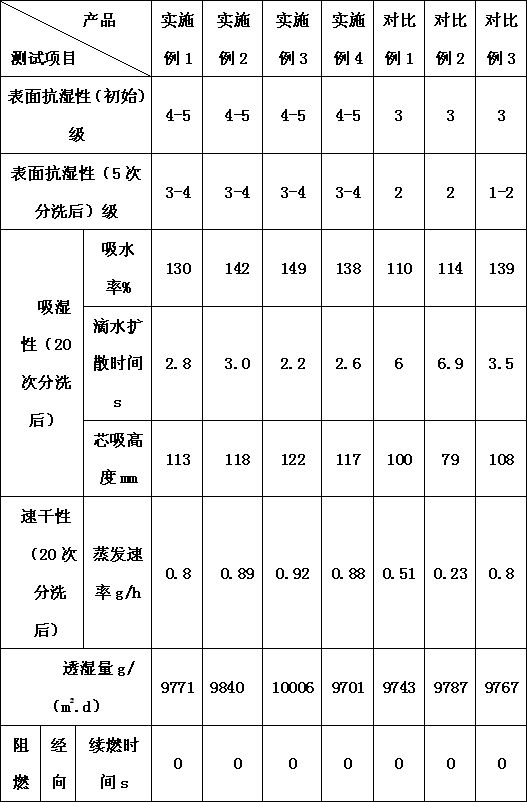

Finishing method of durable flame-retardant, moisture-permeable, single-absorption and single-sided waterproof fabric

ActiveCN112709077ADurable single-sided moisture absorption and quick-drying functionFeel comfortableTextiles and paperPolymer scienceAdhesive

The invention discloses a finishing method of a durable flame-retardant, moisture-permeable, single-absorption and single-sided waterproof fabric. The finishing method is characterized by comprising the following steps of (1) carrying out hot rolling on the front surfaces of aramid fibers and blended fabrics thereof; (2) carrying out coating treatment on the front surface of the fabric by using a waterproof coating adhesive prepared from 1.7-2 parts of a polyacrylic acid thickener, 6 parts of methylbenzene, 77-80 parts of water, 10-12 parts of a hydrocarbon polymer structure fluoride-free waterproof agent, 2-2.5 parts of a blocked isocyanate synergist and 0.3-0.4 part of a polyurethane associative thickening leveling agent, and (3) performing coating treatment on the back surface of the fabric by using a moisture absorption coating adhesive prepared from 1.7-2 parts of a polyacrylic acid thickener, 6 parts of methylbenzene, 84-87 parts of water, 5-7 parts of a polyurethane hydrophilic finishing agent and 0.3-0.4 part of a polyurethane associative thickening leveling agent. The finished fabric has excellent flame retardancy and moisture penetrability, has single-sided waterproofness and single-sided moisture absorption quick-drying property, and is good in washability, breathable, soft, comfortable to wear and convenient to produce and operate.

Owner:DANDONG UNIK TEXTILE

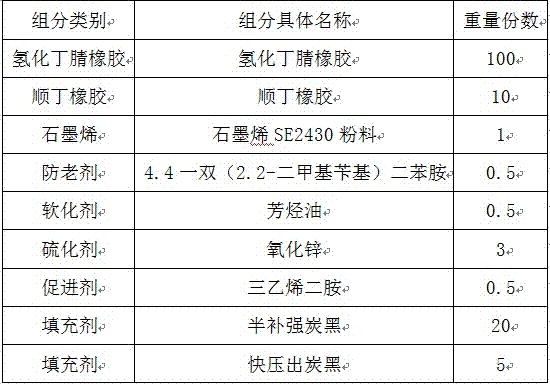

Graphene material synchronous belt rubber compound rubber and preparation method thereof

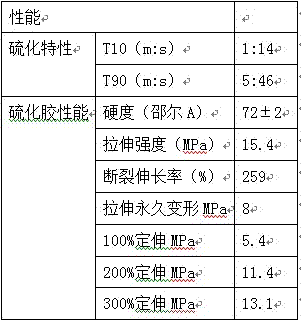

The invention discloses graphene material synchronous belt rubber compound rubber and a preparation method thereof, and the compound rubber comprises the following components: 100 parts of hydrogenated nitrile rubber; 10-20 parts of butadiene rubber; 0.5-10 parts of a filler; 1-5 parts of graphene; 0.5-3 parts of an antioxidant; 0.5-2 parts of a softener; 0-15 parts of a plasticizer; 3-5 parts of a vulcanizing agent; 0.5-2 parts of a promoter; 0-6 parts of Dioctyl phthalate; 0-3 parts of stearic acid; 20-43 parts of semi reinforcing carbon black; 5-20 parts of fast extruding furnace black; 0-10 parts of white carbon black and 0-10 parts of calcium carbonate. The compound rubber has the advantages of stability, good heat and cold tolerance, long-term use size stability, small deformation, good ageing resistance and abrasion resistance, the tensile strength, elongation at break, tensile permanent deformation of the compound rubber all meet the requirements of GB528 standard, and by determination the rubber elastic resilience meets GB / T1681 requirements.

Owner:江苏中胜传动科技有限公司

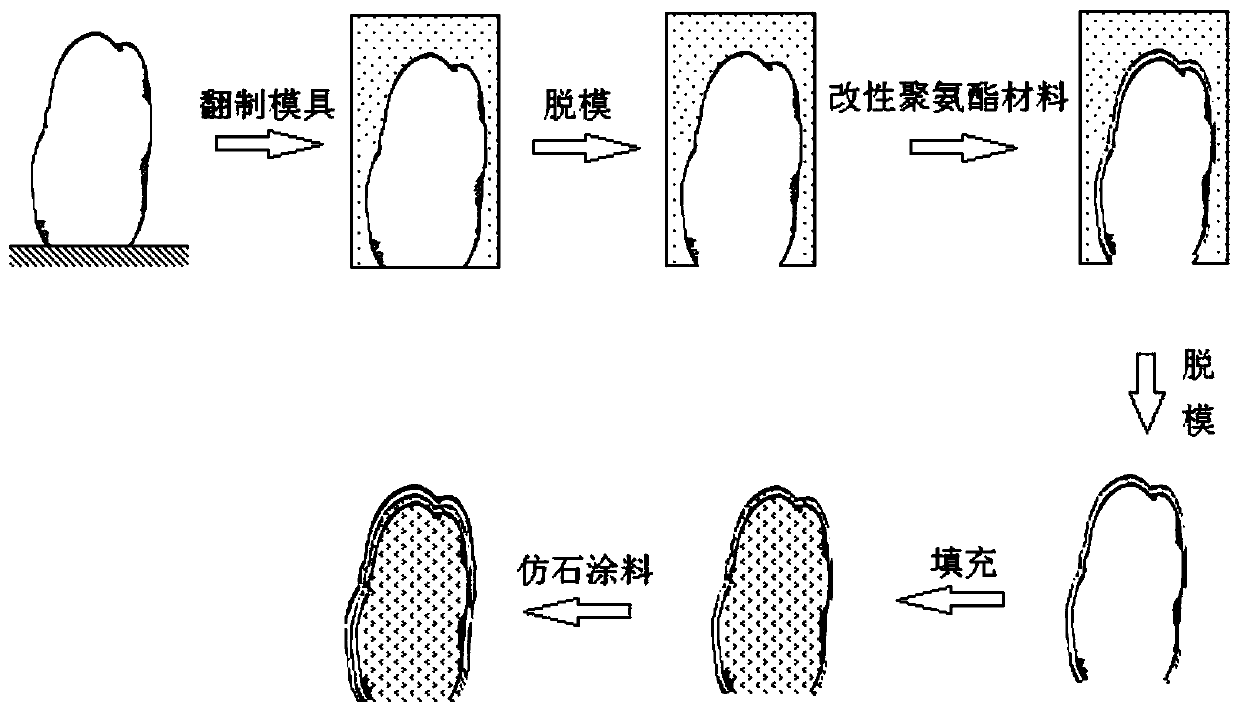

Landscape imitated stone and preparation method thereof

InactiveCN110549777ARealistic effectImprove textureDecorative surface effectsOrnamental structuresHigh densityHeat resistance

The invention relates to a landscape imitated stone and a preparation method thereof, belongs to the technical field of imitated stone preparation, and solves the technical problems of resource waste,high density and difficult transportation of landscape stones with natural stones as materials, and weaker fidelity and higher weight of the landscape stones with the imitated stones as materials inthe prior art. In the landscape imitated stone preparation method, releasing agents are firstly coated on real stones, and liquid-phase silica gels are adopted to prepare duplication molds of the realstones; then, after the releasing agents are coated on the inner surfaces of the duplication molds, modified polyurethane materials are sprayed or brushed for curing and demolding to obtain real stone hard molds; then, inner cavities of the real stone hard molds are filled with polyurethane foamed materials for curing; and finally, stone imitated paint is sprayed on the outer surfaces of the realstone hard molds for drying to obtain the landscape imitated stone. The landscape imitated stone is vivid in effect, good in texture, low in mass, excellent in moisture, ultraviolet, cold and heat resistance and long in service life; and the preparation method is simple and quick and low in production cost, saves the real stones, can machine various complex stone bodies, and is wide in application.

Owner:青岛格林沃德新材料科技有限公司

Recyclable, environmentally friendly laminated fabric

InactiveUS20190217584A1Good adhesivenessGood printabilitySignboardsSynthetic resin layered productsElastomerPolytetramethylene terephthalate

The present invention relates to a recyclable, environmentally friendly laminated fabric, and more particularly to a PBT elastomer laminated fabric produced by laminating a PBT (polybutylene terephthalate) elastomer on a polyester fabric to a predetermined thickness. The laminated fabric is recyclable and has excellent heat resistance, cold resistance, weather resistance, printability, adhesiveness and environmentally friendly properties.

Owner:YOUNGIL

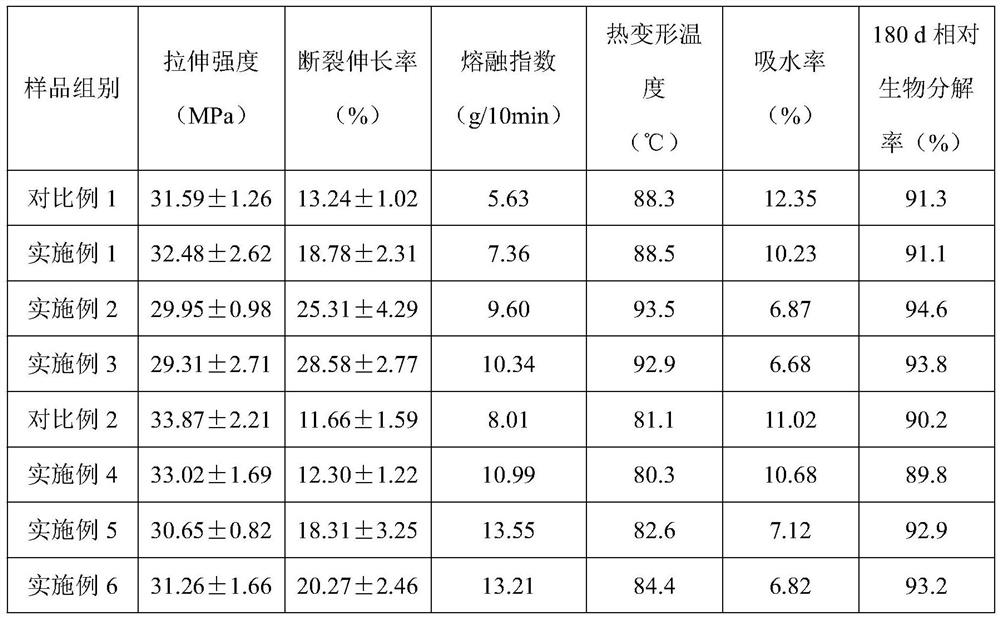

Biodegradable material as well as preparation method and application thereof

ActiveCN114479398AImprove mechanical propertiesEasy to processTablewaresTubular articlesBiodegradable polymerPrepared Material

The invention discloses a biodegradable material as well as a preparation method and application thereof, and belongs to the technical field of biodegradable materials. A certain amount of PHBV, PLA, PBAT and an epoxy chain extender or a certain amount of PHBV, PLA, PBS and an epoxy chain extender are mixed and then subjected to twin-screw extrusion, cooling and slitting, and the biodegradable environment-friendly straw is obtained. The straw prepared by the invention has excellent mechanical property, processability, cold and heat resistance and water resistance, and compared with a traditional straw, the comprehensive performance is further improved, and the product experience feeling is better; the biodegradable polymer is used as a raw material, and the prepared material can be completely biodegraded, has the characteristics of being green, environment-friendly and non-toxic, has positive significance in solving the problem of environmental pollution of disposable straws, and conforms to the green and environment-friendly sustainable development concept.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Nitrile group-containing highly saturated copolymer rubber composition and cross-linked rubber

Owner:ZEON CORP

A body surface coating containing photochromic sunscreen particles

ActiveCN103816056BImproves UV protectionImprove performanceCosmetic preparationsMake-upUltraviolet lightsColor changes

The invention provides a photochromic sunblock particle, a human body surface coating object containing photochromic sunblock particles, and application of the coating object in skin sunblock, body painting and a field hidden material. A photochromic material is added into the human body surface coating object and serves as an ultraviolet absorber, the absorption wavelength is between 280 nm and 400 nm and is just in the wavelength range of UVA (ultraviolet a) and UVB (ultraviolet b) radiating to the ground, the absorption efficiency is high, and the ultraviolet protection effect is improved; the photochromic material is stable in performance, long in service life and good in hot and cold resistance, and the fatigue endurance can reach more than 10,000 times; the surface coating object can be changed into various beautiful and bright colors while absorbing ultraviolet light, can change the colors when applied to a human body and irradiated under sunshine, and can be used for body painting, the field hidden material and the like due to the characteristic; and besides, the ultraviolet intensity of sunlight can be evaluated through observation of the color change condition and the color degree, and a user can be reminded of certain ultraviolet protection.

Owner:TIANJIN UVOS TECH CO LTD

Silicone oil-free anti-hair-loss shampoo

InactiveCN108042403AGuaranteed flexibilityExcellent anti-hair loss effectCosmetic preparationsHair cosmeticsCardingBetaine

The invention relates to silicone oil-free anti-hair-loss shampoo. The silicone oil-free anti-hair-loss shampoo is prepared from the following raw materials in parts by weight: 20 to 25 parts of sodium laureth sulfate, 10 to 13 parts of glyceryl cocoate, 9 to 12 parts of fatty alcohol polylauryl glucoside, 8 to 10 parts of sodium sarcosinate, 3 to 6 parts of betaine, 2 to 5 parts of propylene glycol, 0.2 to 0.8 part of wool grease, 0.8 to 1 part of guar gum hydroxypropyl trimethyl ammonium chloride, 0.6 to 0.8 part of climbazole, 0.5 to 0.8 part of PPG-3-octyl ether, 0.8 to 1 part of cetostearyl alcohol, 2 to 3 parts of Chinese arborvitae twig and leaf extract, 1 to 3 parts of tea seed cake, 2 to 4 parts of white mulberry root-bark essential oil, 0.5 to 1 part of Chinese angelica root essential oil, 1 to 4 parts of tea tree essential oil, 1 to 2 parts of fructus xanthii essential oil, 2 to 3 parts of folium ginkgo water extract and 30 to 50 parts of water. The shampoo can prevent scalppore clogging, hair loss and oil due to use of silicone oil, and can also maintain the smoothness, easy carding, certain glossiness and elasticity of hairs after hair washing, nourish the scalp, reduce hair loss and promote hair regeneration.

Owner:淮安智品企业管理有限公司

Fluororesin seal ring

InactiveUS20150176121A1Good effectImprove cold resistanceEngine sealsOther chemical processesConstant loadAutomatic transmission

A PTFE resin seal ring in which an amorphous carbon film is formed on at least one surface of an abutting part that forms a discontinuous part of the seal ring. Since an amorphous carbon film is formed on the abutting surfaces of the PTFE resin seal ring, sticking does not occur in the abutting part even after constant load is applied at a high temperature. Thus, the PTFE resin seal ring of the present invention exhibits excellent effects of ensuring sealing properties under pressure and slidability under ordinary pressure, and is effectively used as sealing material in, for example, rotation or reciprocation, including hydraulic circuits such as automatic transmissions (A / T) and continuously variable transmissions (CVT) for vehicles.

Owner:NOK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com