Hot-melt reaction type polyurethane adhesive for compounding electronic nylon film

A polyurethane adhesive and nylon film technology, applied in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc. Problems such as inability to maintain adhesion, achieve good permeability, good adhesion, and increase tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

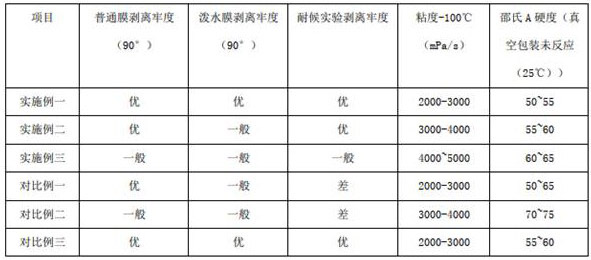

Examples

Embodiment 1

[0027] A hot-melt reactive polyurethane adhesive for electronic nylon film composite, comprising the following parts by mass:

[0028] 25 parts of random network polyester polyols;

[0029] 55 parts of polyether polyols;

[0030] 46 parts of isocyanate;

[0031] 1.25 parts of silane coupling agent;

[0032] (1) Configure random network polyester polyol, mix 1,4-butanediol, 2-methylpropanediol, adipic acid, and neopentyl glycol in a molar ratio of 1:1:1:3 , to synthesize bifunctional polyester polyols with a molecular weight of 2000~3000;

[0033] (2) Prepare a polyol mixture, use the above-mentioned polyester polyol, PEG diol with a molecular weight of 2000, PPG diol with a molecular weight of 1000, and PPG triol with a molecular weight of 400, mix and dehydrate in proportion to obtain a polyol mixture; 2000 The mass ratio of PEG diol with a molecular weight: PPG diol with a molecular weight of 1000: PPG triol with a molecular weight of 400 is 4:6:1;

[0034] (3) Prepare ...

Embodiment 2

[0037] A hot-melt reactive polyurethane adhesive for electronic nylon film composite, comprising the following parts by mass:

[0038] 25 parts of random network polyester polyols;

[0039] 55 parts of polyether polyols;

[0040] 46 parts of isocyanate;

[0041] 1.25 parts of silane coupling agent;

[0042] (1) Configure random network polyester polyol, mix 1,4-butanediol, 2-methylpropanediol, adipic acid, and neopentyl glycol in a molar ratio of 3:1:2:1 , to synthesize bifunctional polyester polyols with a molecular weight of 2000~3000;

[0043] (2) Prepare a polyol mixture, use the above-mentioned polyester polyol, PEG diol with a molecular weight of 2000, PPG diol with a molecular weight of 1000, and PPG triol with a molecular weight of 400, mix and dehydrate in proportion to obtain a polyol mixture; 2000 The mass ratio of PEG diol with a molecular weight: PPG diol with a molecular weight of 1000: PPG triol with a molecular weight of 400 is 4:6:1;

[0044] (3) Prepare ...

Embodiment 3

[0047] A hot-melt reactive polyurethane adhesive for electronic nylon film composite, comprising the following parts by mass:

[0048] 25 parts of random network polyester polyols;

[0049] 55 parts of polyether polyols;

[0050] 46 parts of isocyanate;

[0051] 1.25 parts of silane coupling agent;

[0052] (1) Configure random network polyester polyol, mix 1,4-butanediol, 2-methylpropanediol, adipic acid, and neopentyl glycol in a molar ratio of 1:1:1:3 , to synthesize bifunctional polyester polyols with a molecular weight of 2000~3000;

[0053] (2) Prepare a polyol mixture, use the above-mentioned polyester polyol, PEG diol with a molecular weight of 2000, PPG diol with a molecular weight of 1000, and PPG triol with a molecular weight of 400, mix and dehydrate in proportion to obtain a polyol mixture; 2000 The mass ratio of PEG diol with molecular weight: PPG diol with 1000 molecular weight: PPG triol with 400 molecular weight is 2:7:1;

[0054] (3) Prepare a polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com