Polyvinyl chloride-based wood plastic composite and preparation method thereof

A technology of wood-plastic composite materials and wood powder, which is applied in the field of wood-plastic materials, can solve problems such as difficult to meet the complex requirements of furniture design, the combination of plastic and wood materials is not tight, and the wood effect is not ideal, so as to reduce equipment costs and labor costs. Low cost, excellent appearance, and various colors of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

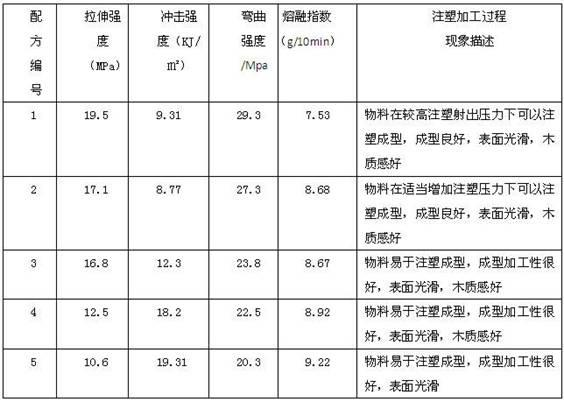

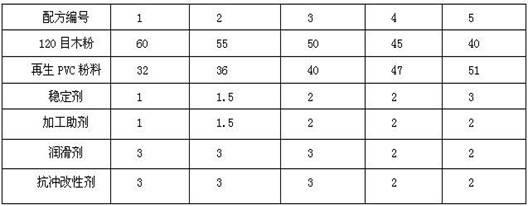

[0025] A PVC-based wood-plastic composite material, which is mainly composed of wood powder or wood chips mixed with plastic, the weight ratio of its components is as follows:, the more preferred weight ratio is PVC 32-51%, stabilizer 1-3% , processing aid 1-2%, impact modifier 2-3%, lubricant 2-3%, wood powder 40-60%; the wood powder fineness is 120 mesh, and the moisture content is 5%. The stabilizer in the components can be organotin stabilizer, the plastic resin can be recycled polyvinyl chloride (PVC) powder, and the lubricant can be TR251. The above-mentioned proportioning raw materials can be purchased from the market.

[0026] A method for making PVC wood-plastic composite materials, including material selection, crushing, proportioning, mixing, kneading, cooling and solidification, cutting finished products and other process steps, wherein

[0027] Material selection: choose commercially available wood flour, such as poplar wood flour, kemu wood flour, etc. The fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com