Impact-resistant toughening PP plastic and preparation method thereof

A technology of impact resistance and toughness, applied in the field of tree PP plastics and its preparation, can solve the problems of poor aging resistance, low temperature brittleness, large molding shrinkage, etc., and achieve good impact resistance, cold and heat resistance, bending performance and Improve the tensile properties and change the effect of poor low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

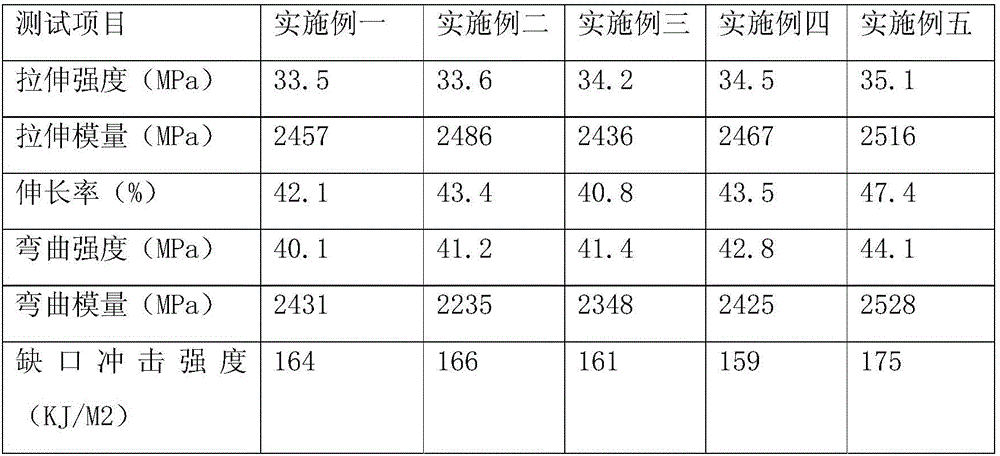

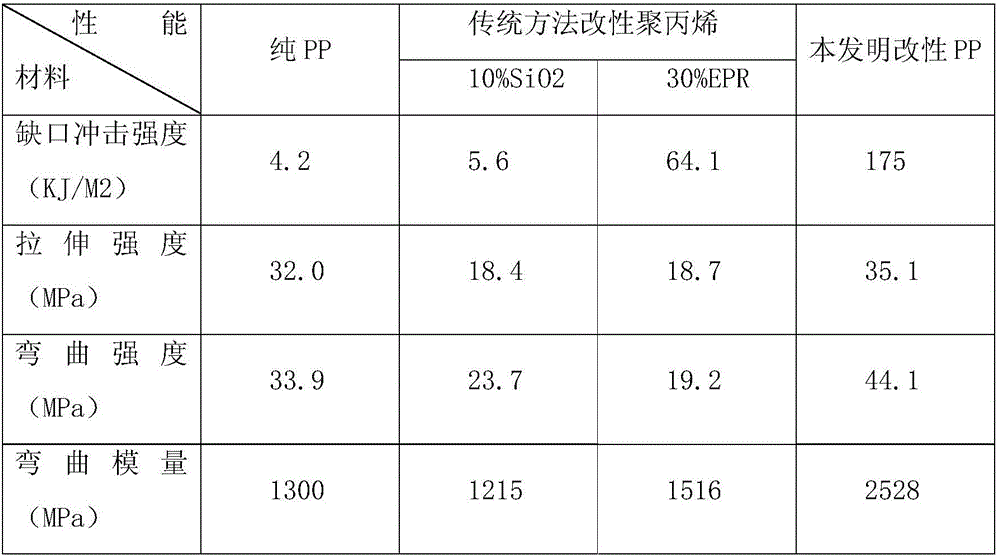

Examples

Embodiment 1

[0027] An impact-resistant and toughened PP plastic, consisting of the following components by weight: 60 parts of PP, 30 parts of MAH-PA, 50 wt% tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionic acid ] 0.5 part of pentaerythritol ester and 50 wt% didodecanyl thiodipropionate, 0.8 part of polytetrafluoroethylene, and 2 parts of layered graphene oxide.

[0028] A preparation method for impact-resistant and toughened PP plastics, comprising the following steps:

[0029] 1. Preparation of layered graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate into a mixed solution of 150-200ml of concentrated sulfuric acid and 10-30ml of concentrated phosphoric acid and stir for 12-24h;

[0030] After the reaction is completed, cool to room temperature, add the obtained dark brown slurry sample into 200-300ml ice water containing 5-10ml concentrated hydrogen peroxide, and the color becomes bright yellow;

[0031] Filter the bright yellow mixed solution, wash with...

Embodiment 2

[0037] An impact-resistant and toughened PP plastic, which consists of the following components in parts by weight: 60 parts of PP, 30-40 parts of MAH-EPR, 50 wt% tetrakis[β-(3,5-tertiary butyl-4-hydroxyphenyl) Propionate] pentaerythritol ester and 0.5 part of 50 wt% didodecanyl thiodipropionate, 0.8 part of paraffin, and 2 parts of layered graphene oxide.

[0038] A preparation method for impact-resistant and toughened PP plastics, comprising the following steps:

[0039] 1. Preparation of layered graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate into a mixed solution of 150-200ml of concentrated sulfuric acid and 10-30ml of concentrated phosphoric acid and stir for 12-24h;

[0040] After the reaction is finished, cool to room temperature, add the obtained dark brown slurry sample into 200-300ml ice water containing 5-10ml concentrated hydrogen peroxide, and the color becomes bright yellow;

[0041] Filter the bright yellow mixed solution, then wash with...

Embodiment 3

[0047] An impact-resistant and toughened PP plastic, consisting of the following components by weight: 60 parts of PP, 30 parts of MAH-ER, 50 wt% tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionic acid ] 0.5 part of pentaerythritol ester and 50 wt% didodecanyl thiodipropionate, 0.8 part of polytetrafluoroethylene, and 2 parts of layered graphene oxide.

[0048] A preparation method for impact-resistant and toughened PP plastics, comprising the following steps:

[0049] 1. Preparation of layered graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate into a mixed solution of 150-200ml of concentrated sulfuric acid and 10-30ml of concentrated phosphoric acid and stir for 12-24h;

[0050] After the reaction is finished, cool to room temperature, add the obtained dark brown slurry sample into 200-300ml ice water containing 5-10ml concentrated hydrogen peroxide, and the color becomes bright yellow;

[0051] Filter the bright yellow mixed solution, then wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com