Landscape imitated stone and preparation method thereof

A technology of imitation of stone and landscape, applied in special decorative structures, coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor fidelity, waste of resources, high density, etc., and achieve long service life, realistic effect and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

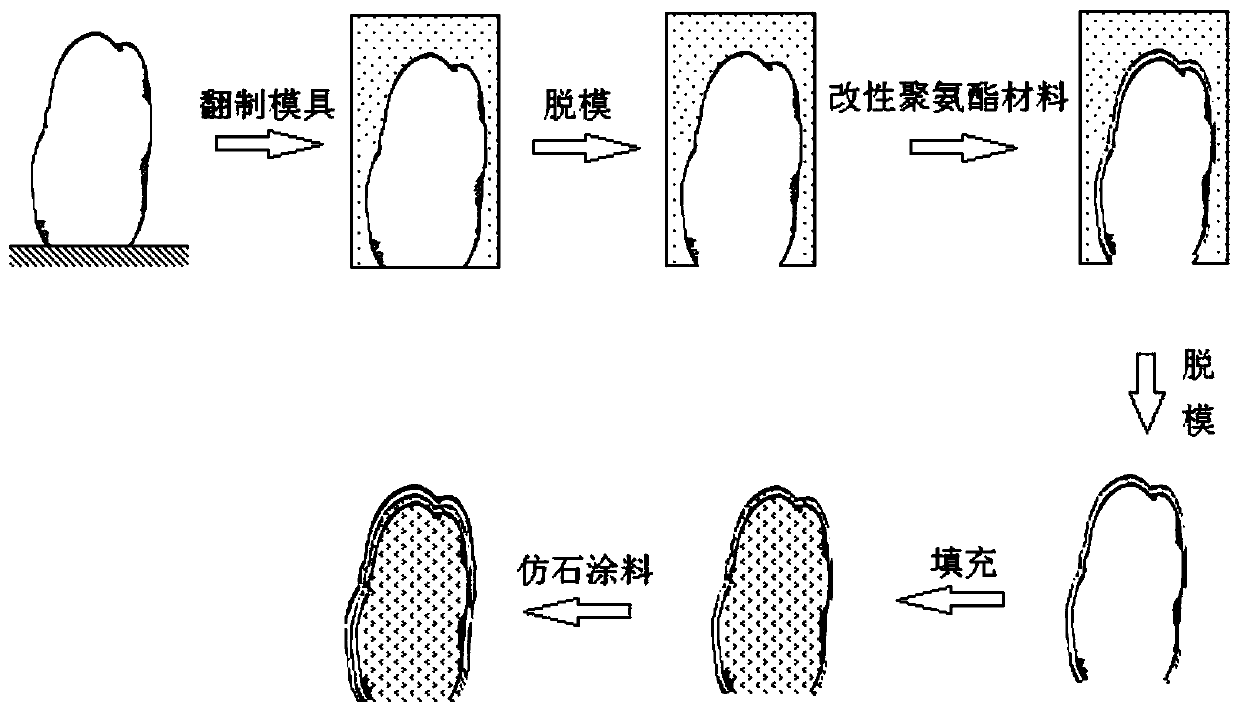

[0029] Such as figure 1 Shown, landscape imitation stone preparation method of the present invention, step is as follows:

[0030] Step 1. Apply a release agent on the real stone, and use liquid phase silica gel to prepare a mold for the real stone;

[0031] Step 2. After applying the mold release agent on the inner surface of the remade mold, spray or brush the modified polyurethane material, solidify, and demould to obtain a real stone hard mold;

[0032] Step 3: Fill the inner cavity of the real stone hard mold with polyurethane foam and cure it;

[0033] Step 4: Spraying imitation stone paint on the outer surface of the real stone hard mold, drying to obtain landscape imitation stone.

[0034] In the above technical scheme, in step 1, liquid-phase silica gel is a mold-turning material commonly used by those skilled in the art, and is usually composed of silica gel and a curing agent. The curing agent mainly includes tetraethyl orthosilicate and organic tin; when the sili...

Embodiment 1

[0042] Step 1. Apply silica gel release agent (Vaseline release paste) on the real stone, and use liquid phase silica gel (HY-6, 100g of silica gel: 2g of curing agent) to prepare the mold of the real stone;

[0043] Step 2. After applying polyurethane release agent (Dakin GA-7500 fluorine high-efficiency release agent) on the inner surface of the remade mold, brush the modified polyurethane material, cure, and release the mold to obtain a real stone hard mold;

[0044] Among them, the modified polyurethane material formula is: 100 parts by weight of polyethylene glycol ether, 70 parts by weight of toluene diisocyanate, 24 parts by weight of glass fiber, 0.3 parts by weight of dibutyltin dilaurate, 0.01 parts by weight of nano-silica, 0.2 parts by weight of It consists of titanium dioxide, 7 parts by weight of thermoplastic styrene-butadiene rubber-maleic anhydride graft, 1 part by weight of zinc stearate, 0.3 part by weight of antioxidant 1010, 0.08 part by weight of paraffin ...

Embodiment 2

[0049] Step 1. Apply silica gel release agent (Vaseline release paste) on the real stone, and use liquid phase silica gel (HY-6, 100g of silica gel: 2g of curing agent) to prepare the mold of the real stone;

[0050] Step 2. After applying polyurethane release agent (Dakin GA-7500 fluorine high-efficiency release agent) on the inner surface of the remade mold, brush the modified polyurethane material, cure, and release the mold to obtain a real stone hard mold;

[0051] Among them, the modified polyurethane material formula is: 100 parts by weight of polyethylene glycol ether, 63 parts by weight of toluene diisocyanate, 12 parts by weight of glass fiber, 0.2 parts by weight of dibutyltin dilaurate, 0.01 parts by weight of nano-silica, 0.2 parts by weight of It consists of titanium dioxide, 5 parts by weight of thermoplastic styrene-butadiene rubber-maleic anhydride graft, 1 part by weight of sodium stearate, 0.2 part by weight of antioxidant 168, 1 part by weight of paraffin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com