Finishing method of durable flame-retardant, moisture-permeable, single-absorption and single-sided waterproof fabric

A durable flame retardant and fabric technology, applied in textiles and papermaking, etc., can solve the problems of interference index, lower moisture absorption function of the inner layer, single function, etc., to improve antistatic and softness, comprehensive wear performance improvement, breathability Good moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

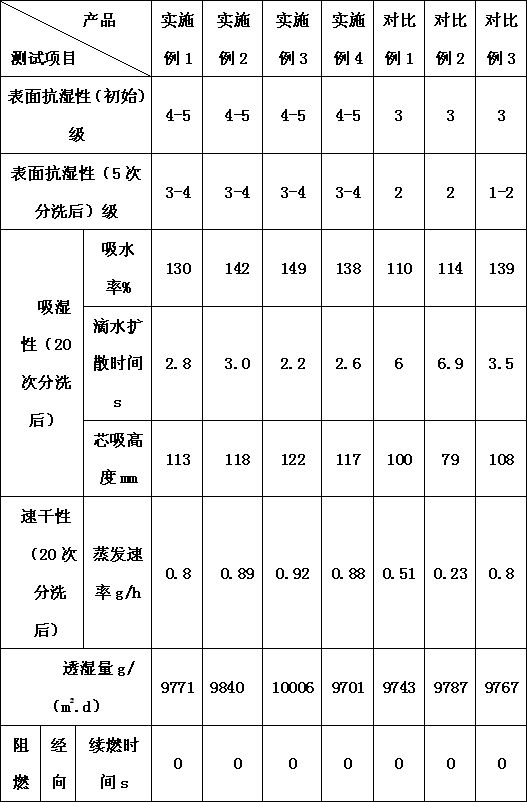

Examples

Embodiment 1

[0051] Base fabric: Aramid fabric, density 78*50 / inch, weight 250g / m 2 ;

[0052] (1) hot rolling treatment

[0053] The front of the fabric is subjected to high-temperature and high-pressure hot rolling, with a pressure of 12MPa, a temperature of 140°C, and a speed of 17m / min to obtain a flat and smooth fiber surface;

[0054] (2) Waterproof coating

[0055] (2-1) Preparation of waterproof coating glue

[0056] Polyacrylic thickener 1.7 parts

[0057] 6 parts of toluene

[0058] 77 parts of water

[0059] Hydrocarbon polymer structure fluorine-free waterproofing agent 12 parts

[0060] Blocked isocyanate synergist 2.5 parts

[0061] Polyurethane associative thickening and leveling agent 0.3 parts

[0062] The above raw materials are mixed and stirred evenly in order to obtain a waterproof coating glue with a viscosity of 1700mPa.s;

[0063] (2-2) Coating treatment

[0064] Use the waterproof coating glue prepared in step (2-1) to coat the front surface of the hot-ro...

Embodiment 2

[0076] Base fabric: aramid fabric, density 92*52 / inch, weight 200g / m 2 ;

[0077] (1) hot rolling treatment

[0078] The front of the fabric is subjected to high-temperature and high-pressure hot rolling, with a pressure of 9MPa, a temperature of 145°C, and a speed of 15m / min to obtain a flat and smooth fiber surface;

[0079] (2) Waterproof coating

[0080] (2-1) Preparation of waterproof coating glue

[0081] Polyacrylic thickener 1.8 parts

[0082] 6 parts of toluene

[0083] 78 parts of water

[0084] Hydrocarbon polymer structure fluorine-free waterproofing agent 11 parts

[0085] Blocked isocyanate synergist 2.3 parts

[0086] Polyurethane associative thickening and leveling agent 0.4 parts

[0087] The above raw materials are mixed and stirred evenly in order to obtain a waterproof coating glue with a viscosity of 1830mPa.s;

[0088] (2-2) Coating treatment

[0089] Use the waterproof coating glue prepared in step (2-1) to coat the front surface of the hot-rol...

Embodiment 3

[0101] Base fabric: aramid-viscose blended fabric, double-layer structure (aramid on the front, aramid and flame-retardant viscose blend on the back), density 100*97 pieces / inch, weight 200g / m 2 ;

[0102] (1) hot rolling treatment

[0103] The front of the fabric is subjected to high-temperature and high-pressure hot rolling, with a pressure of 12MPa, a temperature of 150°C, and a speed of 15m / min to obtain a flat and smooth fiber surface;

[0104] (2) Waterproof coating

[0105] (2-1) Preparation of waterproof coating glue

[0106] 2 parts polyacrylic thickener

[0107] 6 parts of toluene

[0108] 80 parts of water

[0109] Hydrocarbon polymer structure fluorine-free waterproofing agent 10 parts

[0110] Blocked isocyanate synergist 2 parts

[0111] Polyurethane associative thickening and leveling agent 0.3 parts

[0112] The above raw materials are mixed and stirred evenly in order to obtain a waterproof coating glue with a viscosity of 2000mPa.s;

[0113] (2-2) Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Continue burning | aaaaa | aaaaa |

| smoldering time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com