Modified waterborne SBS (styrene-butadiene-styrene) emulsion glue spray and preparation method thereof

A modification and emulsion technology, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of poor initial adhesion, poor initial adhesion, unstable supply, etc., and improve water resistance and weather resistance, speed up the strength building speed, and the effect of fast strength building speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

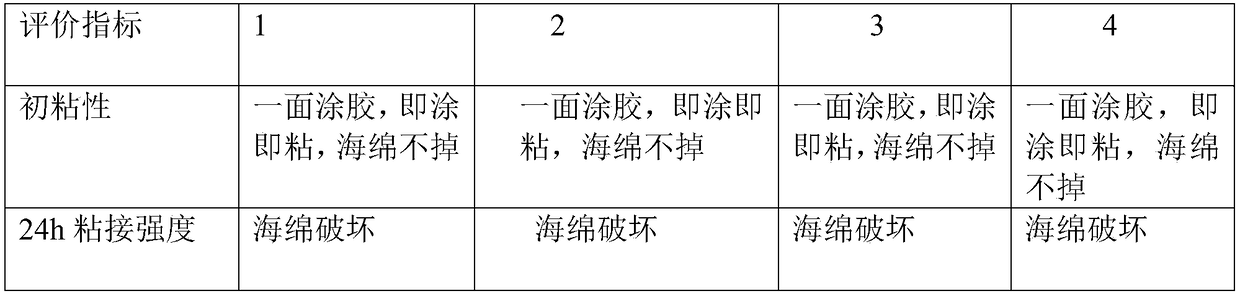

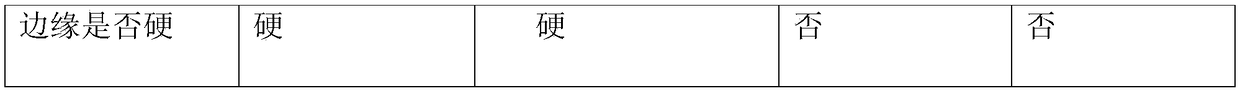

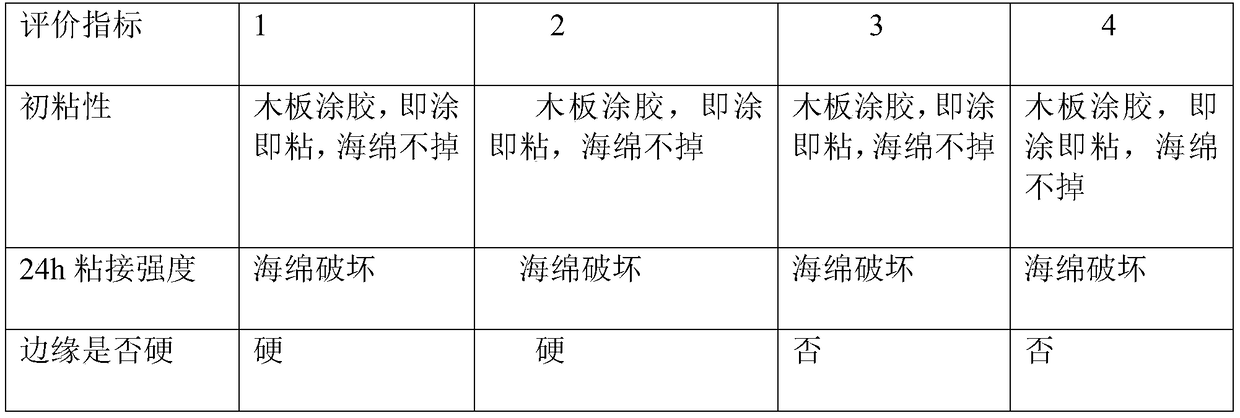

[0036] The modified water-based SBS emulsion spray glue prepared in this example is used for the bonding of mattresses, seat (sleeping) chairs, and sofa sponges, and the wet process is used for bonding.

[0037] The formula of each component of the water-based modified water-based SBS emulsion spray glue of the present embodiment is as follows:

[0038] 50 parts (weight) of modified SBS latex; 24 parts (weight) of styrene-acrylic emulsion; 5 parts (weight) of commercially available tertiary carbon emulsion; 20 parts (weight) of commercially available thickening emulsion; Sodium dodecylbenzenesulfonate 0.2 Parts (weight), mass percentage concentration is 0.1 part (weight) of anti-aging agent 264 aqueous solution of 50%, mass percentage concentration is 0.5 part (weight) of oxalic acid of 20%, thickener hydroxymethyl cellulose 0.2 part (weight).

[0039] Add a certain amount of monomer mixture (butyl acrylate, methyl methacrylate, vinyl acetate, methacrylic acid) into a 500mL th...

Embodiment 2

[0048] The modified water-based SBS emulsion spray glue prepared in this example is used for the bonding of mattresses, seat (sleeping) chairs, sofa sponges and wood boards, and is bonded by a wet process.

[0049] The formulation of each component of the present embodiment modified water-based SBS emulsion spray glue is as follows:

[0050] 65 parts (weight) of modified SBS latex; 19.2 parts (weight) of styrene-acrylic emulsion; 5 parts (weight) of commercially available tertiary carbon emulsion; 10 parts (weight) of commercially available viscosifying emulsion; Sodium dodecylbenzenesulfonate 0.2 Parts (weight), mass percentage concentration is 0.1 part (weight) of anti-aging agent 264 aqueous solution of 50%, mass percentage concentration is 0.3 part (weight) of glycine of 5%, thickener hydroxymethyl cellulose 0.2 part (weight).

[0051] Add a certain amount of monomer mixture (butyl acrylate, methyl acrylate, vinyl acetate, methacrylic acid) into a 500mL three-necked flask,...

Embodiment 3

[0060] It is substantially the same as Example 1, the difference is that:

[0061] The formula of each component of water-based modified water-based SBS emulsion spray glue is as follows:

[0062] 45 parts (weight) of modified SBS latex; 30 parts (weight) of styrene-acrylic emulsion; 10 parts (weight) of commercially available tertiary carbon emulsion; 12 parts (weight) of commercially available viscosifying emulsion; 2-phenyl-1,3- 2 parts (weight) of butadiene; 0.2 part (weight) of sodium dodecylbenzenesulfonate, 0.1 part (weight) of the anti-aging agent 264 aqueous solution that the mass percentage concentration is 50%, and 0.5 part (weight) that the mass percentage concentration is 20% oxalic acid (weight), 0.2 part (weight) of thickener hydroxymethyl cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com