Graphene compounded anti-impact PP (Polypropylene) plastic and preparation method thereof

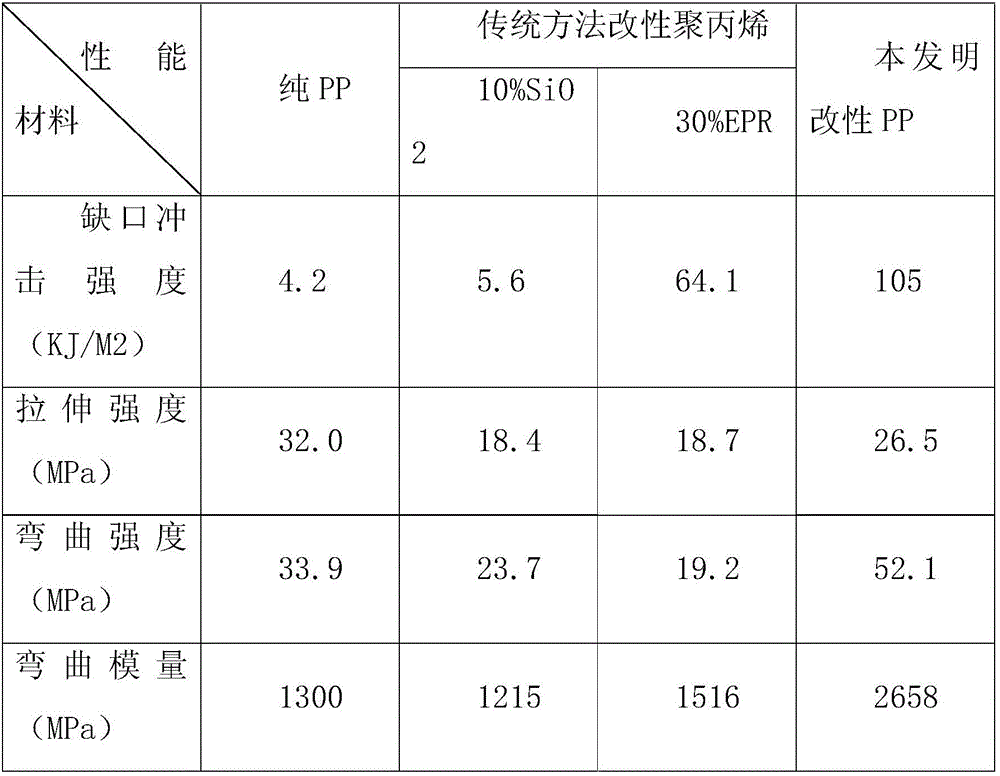

A graphene composite and impact-resistant technology, which is applied in the field of plastic modification and its preparation, can solve problems such as poor aging resistance, large molding shrinkage, and poor dimensional stability, and achieve good impact resistance and cold and heat resistance. Improvement of bending performance and tensile performance, and improvement of poor low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

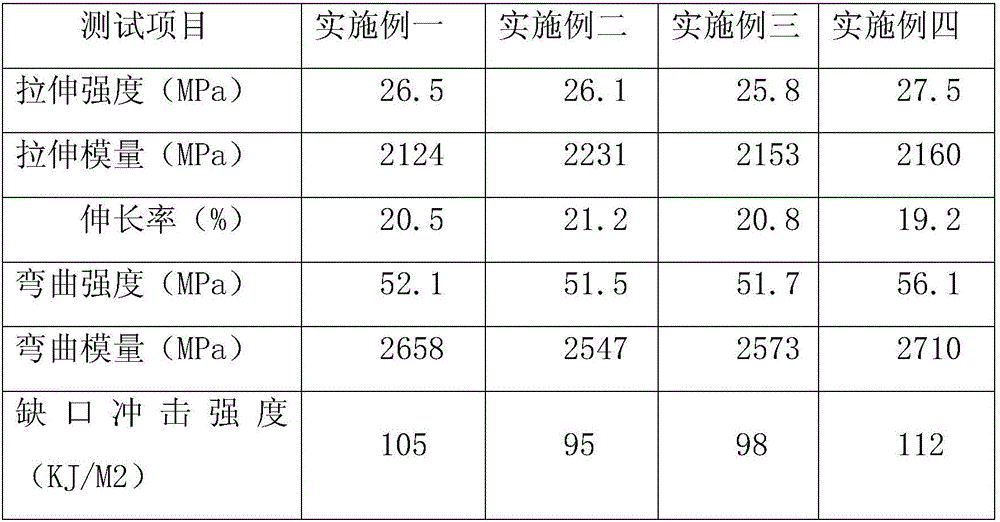

Examples

Embodiment 1

[0023] A graphene composite impact-resistant PP plastic, consisting of the following components in parts by weight: PP 70 parts, 50 wt% tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.3 part of 50 wt% dilauryl thiodipropionate, 0.8 part of polyethylene wax, 0.5 part of 1-vinyltrimethoxysilane, and 1 part of graphene oxide.

[0024] The preparation method of described graphene composite impact-resistant PP plastic, comprises the following steps:

[0025] 1. Preparation of graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate to 150-200ml of concentrated sulfuric acid with a mass concentration of 98% and 10-30ml of concentrated phosphoric acid with a mass concentration of 65% and stir for reaction 12 -24h, then add 5-10ml of hydrogen peroxide with a mass concentration of 30%, continue to stir for 30-60min, vacuum filter, and then place in a vacuum drying oven to dry for 24-48h to prepare graphene oxide.

[0026] 2. Mix 1...

Embodiment 2

[0030] A graphene composite impact-resistant PP plastic, consisting of the following components in parts by weight: PP 70 parts, 50 wt% tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester And 0.3 parts of 50wt% dilauryl thiodipropionate, 0.8 parts of polyethylene wax, 1 part of aminopropyltrimethoxysilane, and 2 parts of graphene oxide.

[0031] The preparation method of described graphene composite impact-resistant PP plastic, comprises the following steps:

[0032] 1. Preparation of graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate to 150-200ml of concentrated sulfuric acid with a mass concentration of 98% and 10-30ml of concentrated phosphoric acid with a mass concentration of 65% and stir for reaction 12 -24h, then add 5-10ml of hydrogen peroxide with a mass concentration of 30%, continue to stir for 30-60min, vacuum filter, and then place in a vacuum drying oven to dry for 24-48h to prepare graphene oxide.

[0033] 2. M...

Embodiment 3

[0037] A graphene composite impact-resistant PP plastic, consisting of the following components in parts by weight: PP 70 parts, 50 wt% tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.3 parts of 50 wt% dilauryl thiodipropionate, 1.5 parts of white oil, 1 part of 1-vinyltrimethoxysilane, and 2 parts of graphene oxide.

[0038] The preparation method of described graphene composite impact-resistant PP plastic, comprises the following steps:

[0039] 1. Preparation of graphene oxide: Add 2.0g of graphite and 10g of potassium permanganate to 150-200ml of concentrated sulfuric acid with a mass concentration of 98% and 10-30ml of concentrated phosphoric acid with a mass concentration of 65% and stir for reaction 12 -24h, then add 5-10ml of hydrogen peroxide with a mass concentration of 30%, continue to stir for 30-60min, vacuum filter, and then place in a vacuum drying oven to dry for 24-48h to prepare graphene oxide.

[0040] 2. Mix 2 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com