Graphene material synchronous belt rubber compound rubber and preparation method thereof

A technology of rubber compounding and graphene, applied in the rubber field, can solve the problems of difficulty in meeting the requirements of wear resistance, anti-aging and cold and heat resistance, and achieve good anti-aging properties, good cold and heat resistance, and high tear resistance. effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

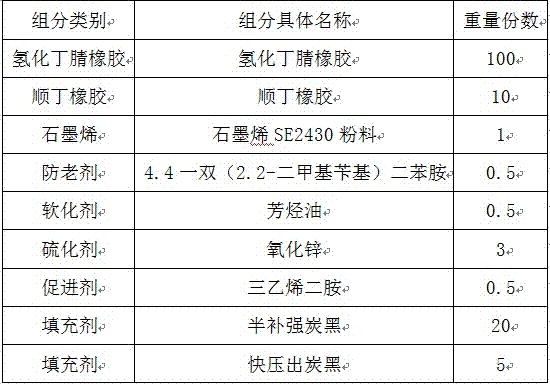

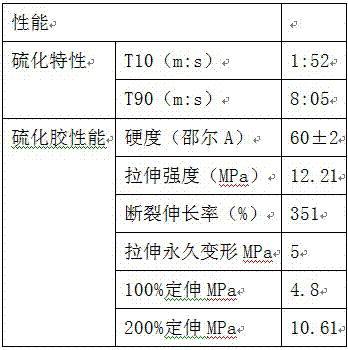

[0031] The graphene material synchronous belt rubber compound of the present embodiment, the composition and content of raw material are as follows:

[0032] Table 1 Example 1 raw material component distribution ratio

[0033]

[0034] The graphene material synchronous belt rubber compound preparation method of the present embodiment comprises the steps:

[0035] 1) Ingredients; According to the formula, prepare various components as raw materials;

[0036] 2) Mastication: Masticate hydrogenated nitrile rubber and butadiene rubber 24 hours in advance;

[0037] 3) Mixing; except for the accelerator and vulcanizing agent, the above components are mixed and run for 1min with a kneader, and hydrogenated nitrile rubber and butadiene rubber are added for mixing. The raw rubber is mixed between the rotors in the kneader. and the severe mechanical action between the rotor and the chamber wall. The shear force generated by the relative speed of the front and rear rollers with a sp...

Embodiment 2

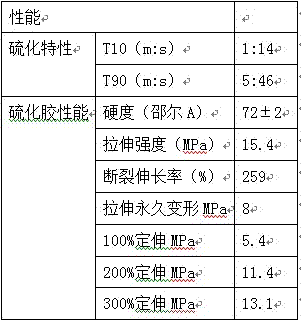

[0045] The graphene material synchronous belt rubber compound of the present embodiment, the composition and content of raw material are as follows:

[0046] Table 3 Example 2 Raw Material Component Distribution Ratio

[0047]

[0048] The graphene material synchronous belt rubber compound preparation method of the present embodiment comprises the steps:

[0049] 1) Ingredients; According to the formula, prepare various components as raw materials;

[0050] 2) Mastication: Masticate hydrogenated nitrile rubber and butadiene rubber 24 hours in advance;

[0051]3) Mixing; except for the accelerator, vulcanizing agent and plasticizer, the above-mentioned components are mixed and run for 1 minute with a kneader, and hydrogenated nitrile rubber and butadiene rubber are added for mixing. The raw rubber is mixed in the kneader It is degraded by the severe mechanical action between the rotors and between the rotor and the chamber wall. The shear force generated by the relative sp...

Embodiment 3

[0058] The graphene material synchronous belt rubber compound of the present embodiment, the composition and content of raw material are as follows:

[0059] Table 5 Embodiment 3 raw material composition distribution ratio

[0060]

[0061] The graphene material synchronous belt rubber compound preparation method of the present embodiment comprises the steps:

[0062] 1) Ingredients; According to the formula, prepare various components as raw materials;

[0063] 2) Mastication: Masticate hydrogenated nitrile rubber and butadiene rubber 24 hours in advance;

[0064] 3) Mixing; except for the accelerator, vulcanizing agent and plasticizer, the above-mentioned components are mixed and run for 1 minute with a kneader, and hydrogenated nitrile rubber and butadiene rubber are added for mixing. The raw rubber is mixed in the kneader It is degraded by the severe mechanical action between the rotors and between the rotor and the chamber wall. The shear force generated by the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com