Extra-high obstruction membrane plated with aluminium oxide through coextrusion and biaxial tension and manufacturing method of extra-high obstruction membrane

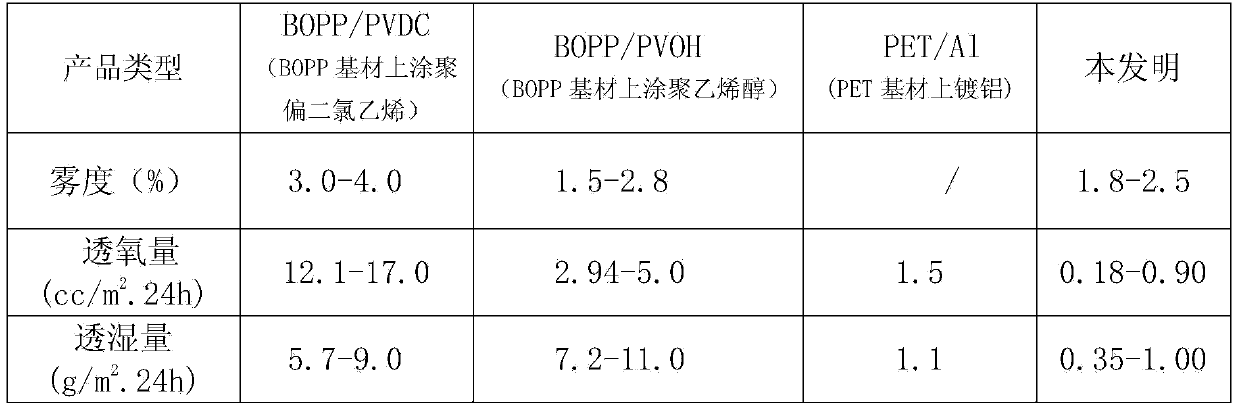

A technology of aluminum oxide plating and biaxial stretching, applied in the field of polymers, can solve the problems of limited barrier properties, short shelf life of food and medicine, and unreachable shelf life, etc., to achieve high transparency and improve the effect of oxygen barrier and moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

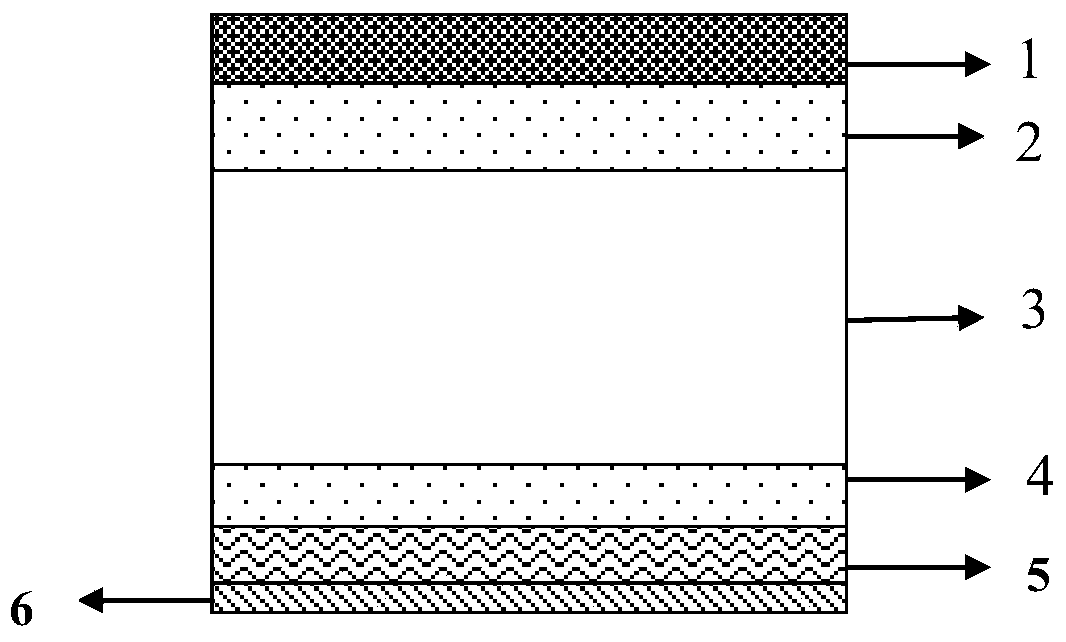

Method used

Image

Examples

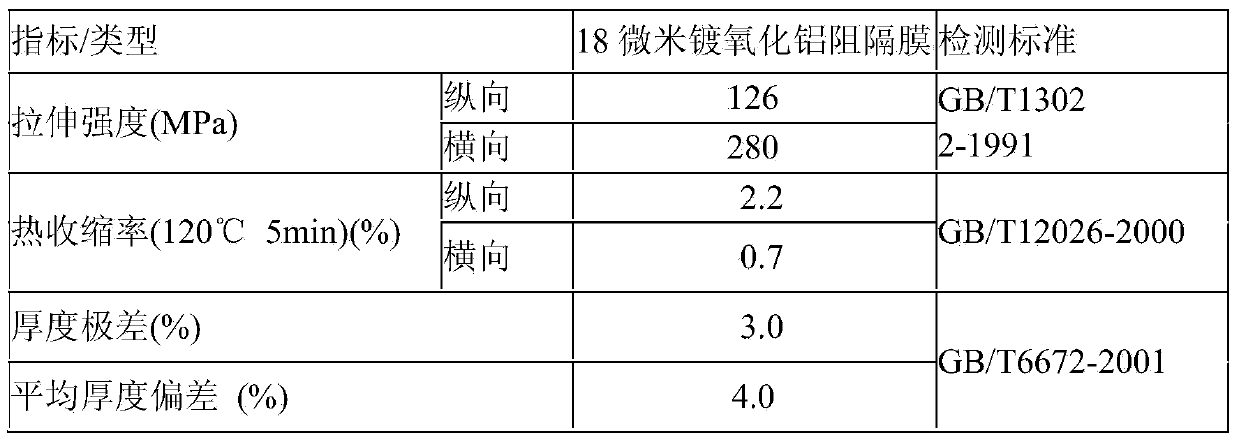

Embodiment 1

[0034] Ingredients: Produce aluminum oxide film with a thickness of 15um. The thickness of the upper layer of the substrate is 0.8um, of which the content of copolymerized polypropylene is 98.0%, and the content of anti-blocking agent is 2.0%; the thickness of the upper layer of the substrate is 2um, of which the content of homopolypropylene is 100%; 97% propylene polymer, 3% copolymerized polyethylene; the thickness of the next layer of the substrate is 0.6um, of which 80% is polypropylene polyvinyl alcohol adhesive resin, and 20% is copolymerized polypropylene resin; the thickness of the lower layer of the substrate is 0.6um, of which the high viscosity is not Crystal copolyamide 50%, polyamide 50%.

[0035] Film production: The five-layer barrier substrate film of the present invention is produced by co-extrusion biaxial stretching process, wherein the temperature of the upper layer extruder: 230 degrees; the temperature of the upper layer extruder: 245 degrees; the tempera...

Embodiment 2

[0039] Ingredients: Produce aluminum oxide film with a thickness of 21.3um. The thickness of the upper layer of the substrate is 1.6um, in which the content of copolymerized polypropylene is 98.0%, and the anti-blocking agent is 2.0%; the thickness of the upper layer of the substrate is 4um, in which the content of homopolypropylene is 100%; 97% propylene polymer, 3% copolymerized polyethylene; the thickness of the next layer of the substrate is 0.9um, of which polypropylene polyvinyl alcohol adhesive resin is 75%, and the copolymerized polypropylene resin is 25%; the thickness of the lower layer of the substrate is 0.8um, of which the high viscosity is not Crystal copolyamide 42%, polyamide 58%.

[0040] Film production: The five-layer barrier substrate film of the present invention is produced by co-extrusion biaxial stretching process, wherein the temperature of the upper layer extruder: 220 degrees; the temperature of the upper layer extruder: 240 degrees; the temperature ...

Embodiment 3

[0044] Ingredients: Produce aluminum oxide film with a thickness of 22um. The thickness of the upper layer of the substrate is 1.2um, of which the content of copolymerized polypropylene is 97.0%, and the content of anti-blocking agent is 3.0%; the thickness of the upper layer of the substrate is 3um, of which the content of homopolypropylene is 100%; 96% polypropylene polymer, 4% copolymerized polyethylene; the thickness of the next layer of the substrate is 0.8um, of which polypropylene polyvinyl alcohol adhesive resin is 85%, and copolymerized polypropylene resin is 15%; the thickness of the lower layer of the substrate is 0.6um, and the high viscosity Amorphous copolyamide 45%, polyamide 55%.

[0045] Film production: The five-layer barrier substrate film of the present invention is produced by co-extrusion biaxial stretching process, wherein the temperature of the upper layer extruder: 232 degrees; the temperature of the upper layer extruder: 248 degrees; the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com