Preparation method of dicyclopentadiene unsaturated polyester resin for high-leveling coatings

A technology of dicyclopentadiene and polyester resin, applied in polyester coatings, coatings, etc., can solve problems such as unsatisfactory construction effects, and achieve good anti-whitening, cost saving, and good wetting and dispersing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

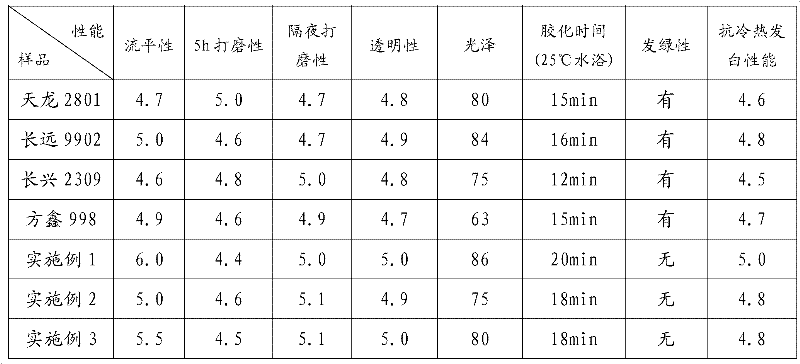

Examples

Embodiment 1

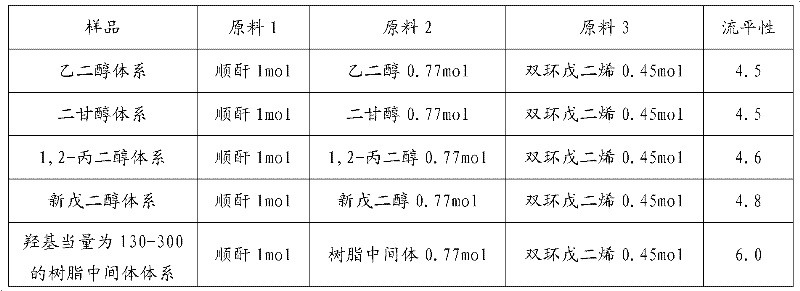

[0020] Synthesis of Resin Intermediate A: Add 1.30 mol of vegetable oleic acid with an acid value of 201, 1.30 mol of glycerin and 1% of the total weight of the feed to a 500ml four-port reactor equipped with nitrogen protection, agitator, thermometer, and water separation condensing device. Hypophosphorous acid color reducer, quickly rise to 230°C, after 1-2 hours of esterification, take a sample to detect the acid value, when the acid value is ≤5, cool down to below 120°C.

[0021] Add 1.13mol maleic anhydride and 1.65mol deionized water to a 500ml four-port reactor equipped with nitrogen protection, stirrer, thermometer, and fractionating column device, stop heating after raising the temperature to 80°C, and naturally raise the temperature to 120°C, After stabilization, 0.64 mol of industrial-grade dicyclopentadiene with a purity of 83% was added dropwise over 2 hours, and then reacted at 120° C. for 2 hours. Then cool down to 100°C, add 0.77mol diethylene glycol, 0.10mol p...

Embodiment 2

[0023] Synthesis of Resin Intermediate B: Add 1.42mol of vegetable oleic acid with an acid value of 195, 0.71mol of pentaerythritol and 1 % hypophosphorous acid color reducing agent, quickly rise to 230°C, after 1-2 hours of esterification, take a sample to detect the acid value, when the acid value is ≤5, cool down to below 120°C.

[0024] Add 1.17mol maleic anhydride and 1.21mol deionized water to a 500ml four-port reactor equipped with nitrogen protection, stirrer, thermometer, and fractionation column device, stop heating after heating up to 80°C, and naturally heat up to 120°C, After stabilization, 0.58 mol of industrial-grade dicyclopentadiene with a purity of 83% was added dropwise over 2 hours, and then reacted at 105° C. for 2 hours. Then cool down to 100°C, add 1.01mol ethylene glycol, 0.32mol glycerin, 0.24mol fumaric acid, 0.04mol resin intermediate B, and triphenyl phosphite accounting for 0.16‰ of the total weight of the feed and 0.04‰ of methyl hydroquinone, he...

Embodiment 3

[0026] Synthesis of Resin Intermediate C: Add 1.30 mol of vegetable oleic acid with an acid value of 208, 1.30 mol of glycerin and 1% of the total amount of feed to a 500ml four-port reactor equipped with nitrogen protection, agitator, thermometer, and water separation condensing device Hypophosphorous acid color reducer, quickly rise to 230°C, after 1-2 hours of esterification, take a sample to detect the acid value, when the acid value is ≤5, cool down to below 120°C.

[0027]Add 1.14mol maleic anhydride and 1.18mol deionized water to a 500ml four-port reactor equipped with nitrogen protection, stirrer, thermometer and fractionation column device, stop heating after heating up to 80°C, and naturally heat up to 120°C After stabilization, 0.65 mol of industrial-grade dicyclopentadiene with a purity of 83% was added dropwise in 2 hours, and then reacted at 140° C. for 2 hours. Then cool down to 100°C, add 0.78mol neopentyl glycol, 0.09mol pentaerythritol, 0.23mol fumaric acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com