Universal styrene-acrylic emulsion for interior and exterior walls and preparation method thereof

A styrene-acrylic emulsion, interior and exterior wall technology, applied in coatings and other directions, can solve problems affecting the final stability and application performance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

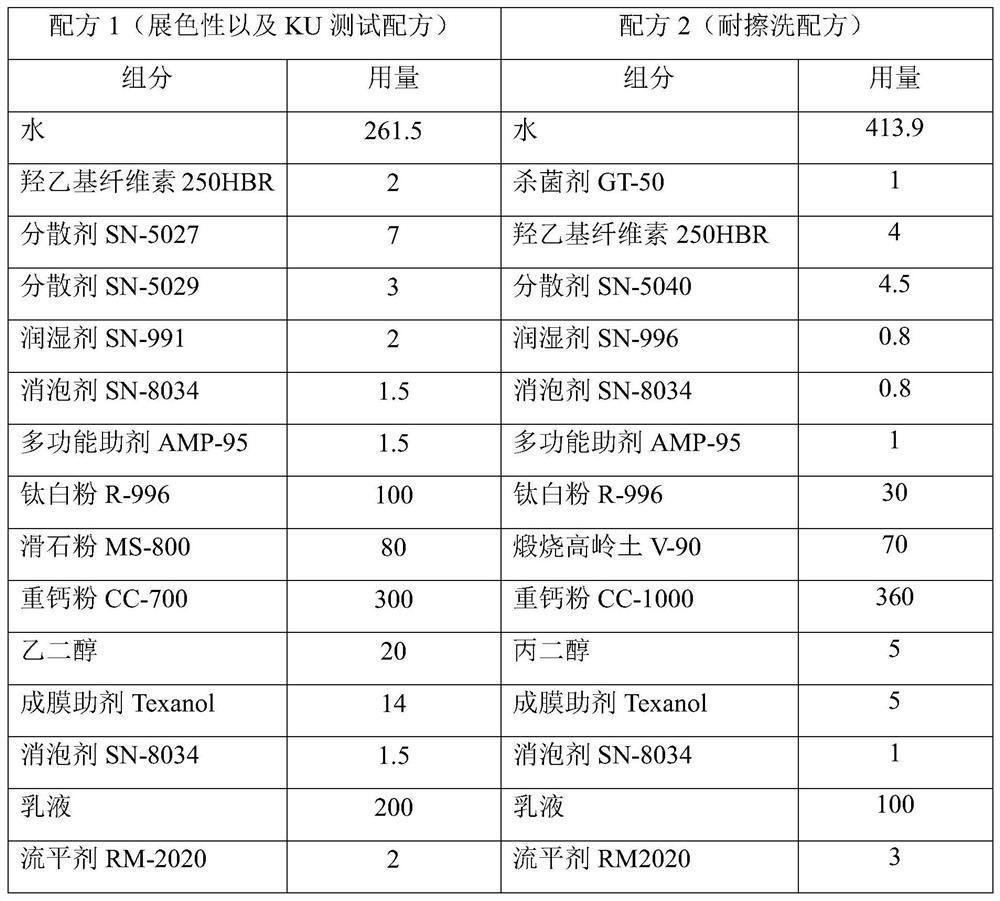

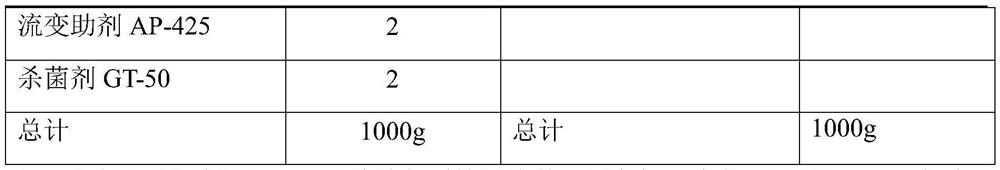

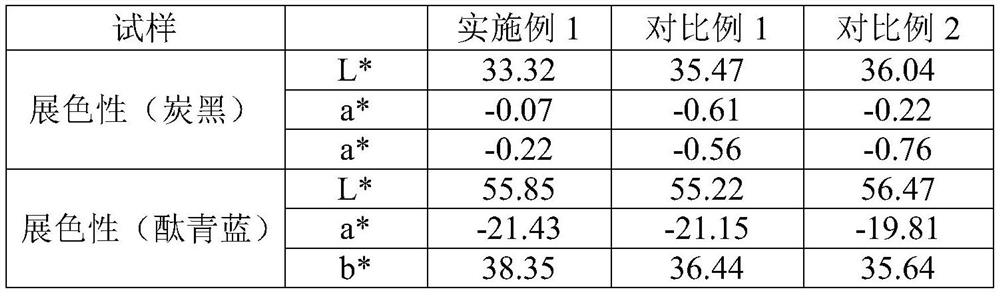

Examples

Embodiment 1

[0032] Embodiment 1 A kind of interior and exterior wall styrene-acrylic emulsion and preparation method thereof

[0033] The present embodiment is made by following raw material proportioning, calculates by weight:

[0034] 320 parts of styrene, 200 parts of butyl acrylate, 130 parts of isooctyl acrylate, 17 parts of acrylamide, 13 parts of acrylic acid, 4 parts of methacrylic acid, 3 parts of vinyl triethoxysilane, 4 parts of sodium persulfate, 1 part of dodecyl mercaptan, 9 parts of sodium lauryl ether sulfate, 3 parts of sulfosuccinic acid alkyl alcohol ether monoester disodium salt, 2 parts of allyloxy fatty alcohol oxyethylene ether sodium sulfate, and the number of EO is 9, 5 parts of fatty alcohol polyoxyethylene ether, 5 parts of ammonia water, and 750 parts of water.

[0035] Its preparation method comprises the following steps:

[0036] (1) Synthesis stage

[0037] a. Preparation of pre-emulsion: add 350 parts of deionized water and 14 parts of emulsifier, turn o...

Embodiment 2

[0043] Embodiment 2 A kind of interior and exterior wall styrene-acrylic emulsion and preparation method thereof

[0044] The present embodiment is made by following raw material proportioning, calculates by weight:

[0045] 330 parts of styrene, 180 parts of butyl acrylate, 140 parts of isooctyl acrylate, 16 parts of acrylamide, 12 parts of acrylic acid, 4 parts of methacrylic acid, 2 parts of vinyltrimethoxysilane, 4 parts of ammonium persulfate, isodecyl 2 parts of dialkyl mercaptan, 10 parts of potassium lauryl ether sulfate, 3 parts of disodium salt of fatty alcohol ether sulfosuccinate, 2 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate, fatty alcohol with EO number of 10 4 parts of polyoxyethylene ether, 10 parts of sodium hydroxide, 750 parts of water.

[0046] The preparation method comprises the following steps:

[0047] (1) Synthesis stage

[0048] a. Preparation of pre-emulsion: add 350 parts of deionized water and 10 parts of emulsifier, turn ...

Embodiment 3

[0054] Embodiment 3 A kind of interior and exterior wall styrene-acrylic emulsion and preparation method thereof

[0055] The present embodiment is made by following raw material proportioning, calculates by weight:

[0056] 400 parts of styrene, 300 parts of butyl acrylate, 200 parts of isooctyl acrylate, 25 parts of acrylamide, 20 parts of acrylic acid, 3 parts of methacrylic acid, 2 parts of 3-methacryloxypropyltrimethoxysilane, 5 parts of ammonium persulfate, 5 parts of isododecyl mercaptan, 8 parts of sodium lauryl ether sulfate, 4 parts of disodium salt of fatty alcohol ether sulfosuccinate, 3 parts of sodium allyloxy fatty alcohol oxyethylene ether sulfate , 3 parts of fatty alcohol polyoxyethylene ether with EO number of 10, 10 parts of ammonia water, and 850 parts of water.

[0057] The preparation method comprises the following steps:

[0058] (1) Synthesis stage

[0059]a. Preparation of pre-emulsion: add 400 parts of deionized water and 12 parts of emulsifier, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com