A kind of aqueous polymer polyurethane dispersant and preparation method thereof

A polyurethane dispersant and water-based polymer technology, applied in chemical instruments and methods, transportation and packaging, coatings, etc., can solve problems such as application restrictions, reduce system viscosity, enhance water resistance and salt spray resistance, and versatility wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

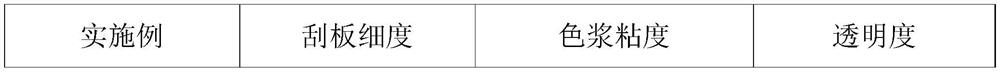

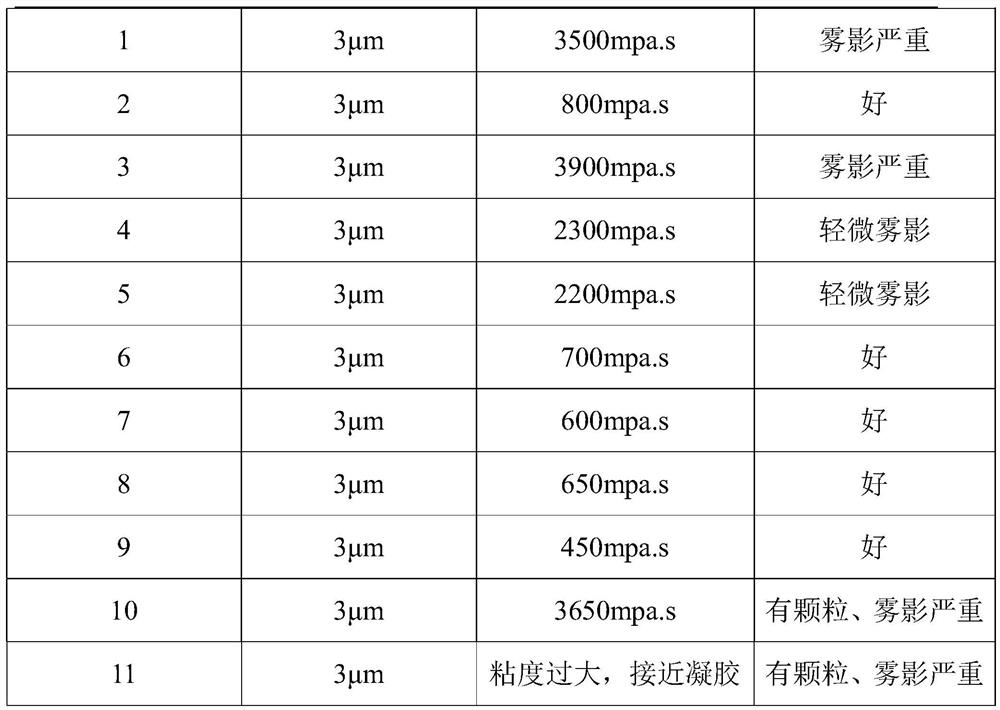

Examples

Embodiment 1

[0022] This embodiment provides a water-based polymer polyurethane dispersant and a preparation method of the dispersant.

[0023] The raw materials used to prepare the dispersant of this embodiment are: Desmodur IL1451 BA, styrenated phenol, MPEG-350, N'N-dimethylethanolamine, butyl acetate, distilled water.

[0024] The preparation method of dispersant specifically comprises the following steps:

[0025] 1) Weigh 10g of butyl acetate and add it to a four-necked flask equipped with a stirring and condensing device. Under stirring, add 20g of Desmodur IL1451 BA and mix evenly, then add 4.30g of styrenated phenol, and protect with nitrogen. At 65°C, keep warm for 1h;

[0026] 2) Weigh 6.17g of MPEG-350, add it to a four-necked flask, and keep it warm for 1.5h;

[0027] 3) Add 0.63g of N'N-dimethylethanolamine dropwise, keep stirring the reaction, the dropwise addition is completed in 0.5h, keep warm for 0.5h and raise the temperature to 85°C, then keep warm for 2h, then lower...

Embodiment 2

[0029] This embodiment provides a water-based polymer polyurethane dispersant and a preparation method of the dispersant.

[0030] The raw materials used to prepare the dispersant of this example include: Desmodur IL1451 BA, styrenated phenol, MPEG-500, DMP-30, butyl acetate, and distilled water.

[0031] The preparation method of dispersant specifically comprises the following steps:

[0032] 1) Weigh 10g of butyl acetate and add it to a four-necked flask equipped with a stirring and condensing device. Under stirring, add 20g of Desmodur IL1451 BA and mix evenly, then add 7.17g of styrenated phenol, and protect with nitrogen. At 70°C, keep warm for 1.5h;

[0033] 2) Weigh 5.29g of MPEG-500, add it to a four-necked flask, and keep it warm for 1h;

[0034] 3) Weigh 1.87g of DMP-30 and 5g of butyl acetate and mix them uniformly in advance, add the mixture dropwise, and keep stirring the reaction. After 1 hour of dropwise addition, raise the temperature to 95°C after 1 hour of ...

Embodiment 3

[0036] This embodiment provides a water-based polymer polyurethane dispersant and a preparation method of the dispersant. The raw materials used to prepare the dispersant of this embodiment are: Desmodur IL1451 BA, styrenated phenol, AEO-9, N'N-diethylethanolamine, butyl acetate, distilled water.

[0037] The preparation method of dispersant specifically comprises the following steps:

[0038] 1) Weigh 10g of butyl acetate and add it to a four-necked flask equipped with a stirring and condensing device, under stirring, add 20g of Desmodur IL1451 BA and mix evenly, add 2.87g of styrenated phenol, nitrogen protection, in At 70°C, keep warm for 0.5h;

[0039] 2) Weigh 14.38g of AEO-9, add it to a four-necked flask, and keep it warm for 2 hours;

[0040] 3) Add 0.41g of N'N-diethylethanolamine dropwise, keep stirring the reaction, the dropwise addition is completed in 0.5h, keep warm for 0.5h and raise the temperature to 90°C, then keep warm for 2h, then lower the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com