A kind of active controllable radical vinyl polymer and its polymerization method

A vinyl polymer and polymerization method technology, applied in the coating and other directions, can solve the problems of difficult to achieve industrialization, reduce production costs, harsh reaction conditions, etc., and achieve a wide range of reaction temperatures, low equipment costs, and narrow molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

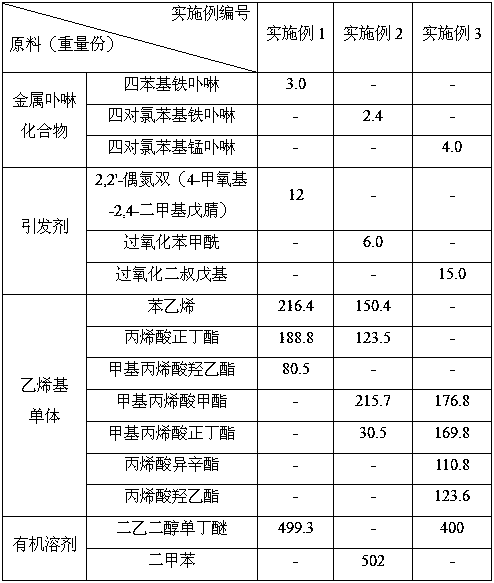

Embodiment 1~3

[0044]

[0045] Note: "-" in the table means not added.

Embodiment 1

[0047] (1) According to the parts by weight of each raw material described in Table 1, Example 1, the organic solvent is placed in a closed flask with a thermometer, a condensing water separator and a stirring device, and after adding a metalloporphyrin compound and an initiator, it is filled with Enter nitrogen, replace the air in the airtight flask, stir and react for 10min to obtain the initiator solution;

[0048] (2) According to the parts by weight of the raw materials described in Table 1, Example 1, vinyl monomers were added to the initiator solution obtained in step (1), stirred and reacted for 10 minutes, and heated to 50°C under the protection of nitrogen, and polymerized for 10 hours After cooling to room temperature, Serve.

[0049] After testing, the solid content of the active controllable free radical vinyl polymer obtained by the method of the present invention is 49.8%, and the vinyl monomer conversion rate is about 98.50% according to the solid content calcu...

Embodiment 2

[0052] (1) According to the parts by weight of each raw material described in Table 1, Example 2, the organic solvent is placed in a closed flask with a thermometer, a condensation water separator and a stirring device, and after adding the metalloporphyrin compound and the initiator, the Enter nitrogen, replace the air in the airtight flask, stir and react for 20min to obtain the initiator solution;

[0053] (2) According to the parts by weight of the raw materials described in Table 1, Example 2, vinyl monomers were added to the initiator solution obtained in step (1), stirred and reacted for 20 minutes, heated to 95°C under nitrogen protection, and polymerized for 12 hours After cooling to room temperature, Serve.

[0054] After testing, the solid content of the active controllable free radical vinyl polymer obtained by the method of the present invention is 49.5%, and the vinyl monomer conversion rate is about 98.70% according to the solid content calculation; the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com