Water-dispersible light stabilizer and preparation method thereof

A light stabilizer and dispersibility technology, which is applied in the field of water-based environmental protection product additives, can solve the problems of poor weather resistance of water-based coatings, limit the application of water-based products, and low light stabilizer content, and achieve easy dispersion into water and good water resistance. Chemical effect and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of water dispersible light stabilizer, comprising the following steps:

[0036] (1) Get 20 mass parts of acetone, 10 mass parts of propylene glycol butyl ether and 3 mass parts of azobisisobutyronitrile in a 150mL four-necked flask, put 10 mass parts of acrylic acid, 10 mass parts of butyl acrylate , 24 parts by mass of methyl methacrylate, 10 parts by mass of epoxy resin E51 and 1 part by mass of azobisisobutyronitrile were added to the dropping funnel, and then the temperature was raised to 80°C, and started under stirring at 190r / min Add the liquid in the dropping funnel dropwise, and finish adding dropwise in 2 hours to obtain a water-based resin prepolymer;

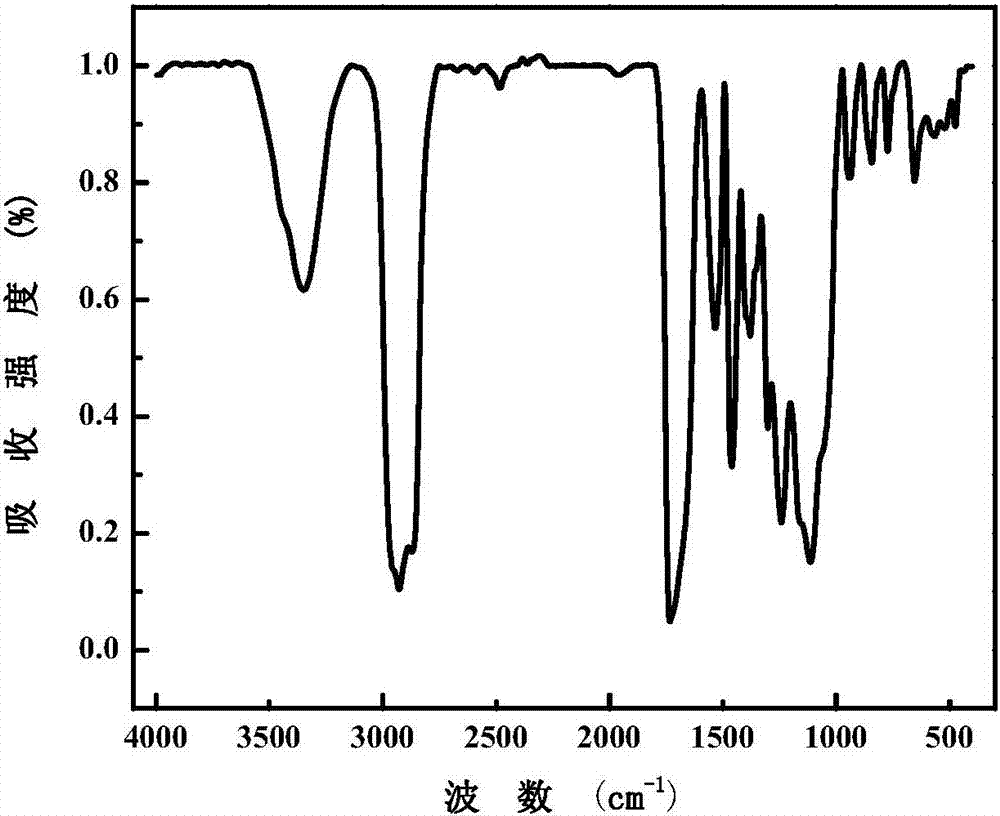

[0037] (2) Take 25 parts by mass of water-based resin prepolymer, 1 part by mass of triethylamine, 60 parts by mass of light stabilizer bis(1-octyloxy-2,2,6,6-tetramethyl-4 -piperidinyl) sebacate, 0.1 parts by mass of alkylphenol polyoxyethylene ether, 0.1 parts by mass of sodium dodecylb...

Embodiment 2

[0041] A preparation method of water dispersible light stabilizer, comprising the following steps:

[0042] (1) Get 30 mass parts of propylene glycol methyl ether and 2 mass parts of azobisisobutyronitrile in a 150mL four-necked flask, put 6 mass parts of acrylic acid, 24 mass parts of butyl acrylate, and 10 mass parts of formaldehyde Add methyl acrylate, 10 parts by mass of epoxy resin E20 and 1 part by mass of azobisisobutyronitrile into the dropping funnel, then raise the temperature to 85°C, and start dropping into the dropping funnel under stirring at 130r / min The liquid, 2h is added dropwise, and the aqueous resin prepolymer is obtained;

[0043] (2) Get 35 parts by mass of water-based resin prepolymer, ethylenediamine of 5 parts by mass, light stabilizer 2-cyano-3, ethyl diphenylacrylate of 50 parts by mass, 0.1 part by mass of ten Sodium dialkylbenzenesulfonate and 15 parts by mass of water were stirred for 25 minutes at 25° C. and a rotation speed of 150 r / min to pre...

Embodiment 3

[0046] A preparation method of water dispersible light stabilizer, comprising the following steps:

[0047] (1) Get 50 parts by mass of diphenylmethane diisocyanate, 20 parts by mass of polyether diol (molecular weight 800), 20 parts by mass of N-methylpyrrolidone, 5 parts by mass of 2,2-dimethylol propionic acid and Heat 0.2 parts by mass of N,N-dimethylcyclohexylamine in a 150mL four-necked flask with good airtightness to 50°C, and keep it warm for 3h under the stirring condition of 180r / min to prepare the water-based resin prepolymerized thing;

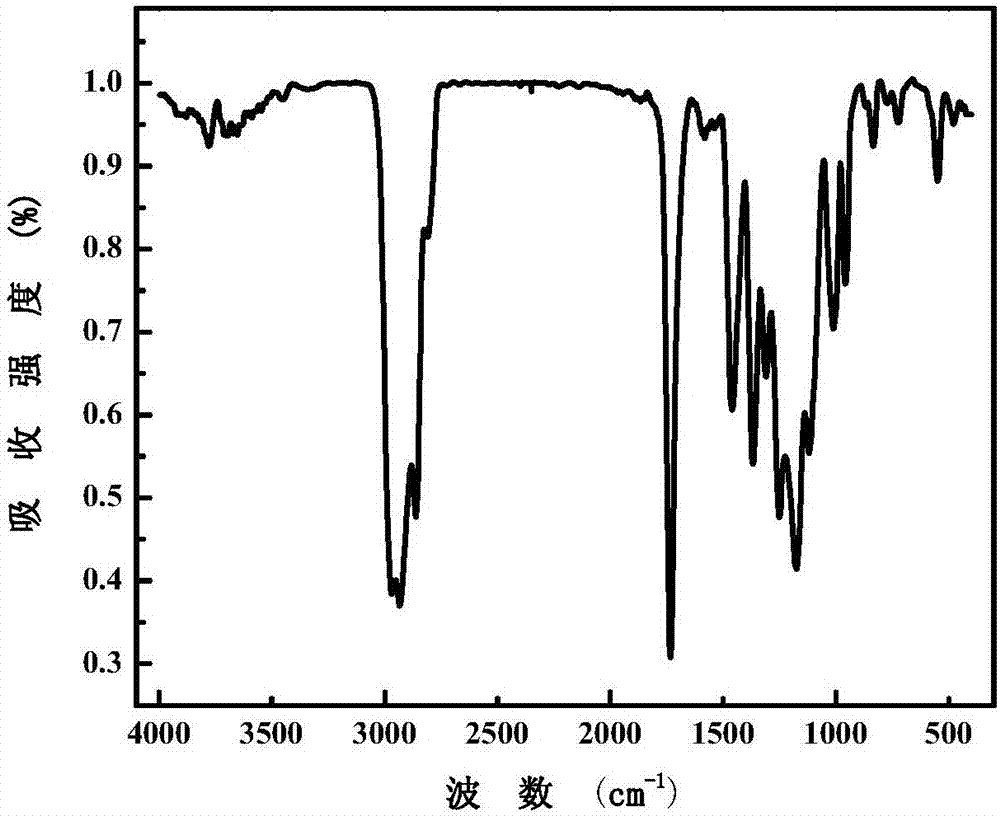

[0048] (2) Take 30 parts by mass of water-based resin prepolymer, 3 parts by mass of triethylamine, and 68 parts by mass of light stabilizer bis(1-octyloxy-2,2,6,6-tetramethyl-4 -piperidinyl) sebacate, 2 mass parts of hydroxymethyl cellulose, 2 mass parts of polyethylene glycol and 0.1 mass parts of water, stirred at 150°C and 100r / min for 45min to prepare Water dispersible light stabilizer.

[0049] The various performance test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com