Exhaust gas freezing recovery treatment device

A technology for recovery and treatment of tail gas, applied in the direction of steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the resistance of mass transfer and heat transfer, unable to meet modern production, and increasing energy consumption of evaporation. The effect of saving evaporative energy consumption, significant energy saving and emission reduction, and increasing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

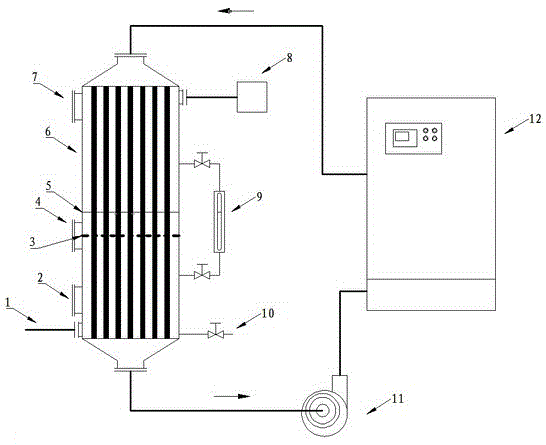

[0016] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0017] Such as figure 1 The tail gas freezing recovery treatment device shown includes a heat exchanger 6, wherein the surface of the heat exchanger 6 is covered with an insulating layer, and there are multiple heat exchange tubes in the heat exchanger 6, and the heat exchange tubes are connected with the chiller 12 and the cold water pump 11 To form a circulation system, the temperature of the liquid in the tube side of the heat exchange tube can be set to be between minus 10 degrees and 10 degrees above zero; the shell side of the heat exchange tube is filled with a certain height of packing ring and organic solvent, the packing ring is used For dispersing gas, the organic solvent liquid level 5 is slightly higher than the packing ring height 3; the exhaust gas inlet pipe 1 containing organic solvent vapor and the valve 10 for organic solvent discharge are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com