Water-based roll printing nickel paste special for MLCC and preparation method of water-based roll printing nickel paste

A technology of nickel paste and roll printing, applied in the field of special roll printing nickel paste for water-based MLCC and its preparation, which can solve the problem of high content of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

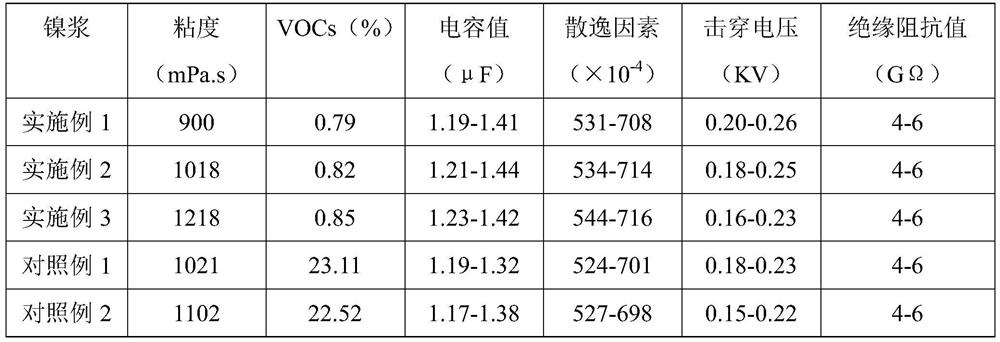

Examples

Embodiment 1

[0031] The preparation method of embodiment 1 water-based MLCC special roller printing nickel paste, comprises the following steps:

[0032] S1, mix 1 part of hydroxyethyl cellulose, 0.5 part of hydroxypropyl cellulose, 0.5 part of hydroxypropyl methyl cellulose with 98 parts of pure water, heat to 45°C, and use a high-speed shear disperser at a speed of 1200rpm After stirring for 30 minutes in the middle, a water-soluble resin binder with a solid content of 2% was obtained;

[0033] S2, 80.5 parts of nickel powder, 18.5 parts of purified water, and 1 part of additives were stirred in a high-speed shear disperser at a speed of 1200rpm for 5 minutes, and then transferred to a 3000rpm nano-sand mill for grinding for 15 minutes to obtain a nano-nickel dispersion;

[0034] S3, 70 parts of nano-barium titanate, 2 parts of nano-magnesia, 2 parts of nano-yttrium oxide, 25 parts of pure water, and 1 part of dispersant were stirred in a high-speed shear disperser at a speed of 1200rpm ...

Embodiment 2

[0037] Embodiment 2, the preparation method of water-based MLCC special roller printing nickel paste, comprises the following steps:

[0038] S1, mix 1 part of hydroxyethyl cellulose, 0.5 part of hydroxypropyl cellulose, 0.5 part of hydroxypropyl methyl cellulose with 98 parts of pure water, heat to 45°C, and use a high-speed shear disperser at a speed of 1200rpm After stirring for 30 minutes in the middle, a water-soluble resin binder with a solid content of 2% was obtained;

[0039] S2, 82.5 parts of nickel powder, 16.5 parts of pure water, and 1 part of additives were stirred in a high-speed shear disperser at a speed of 1200 rpm for 5 minutes, and then transferred to a 3000 rpm nano-sand mill for grinding for 15 minutes to obtain a nano-nickel dispersion;

[0040] S3, 70 parts of nano-barium titanate, 2 parts of nano-magnesia, 2 parts of nano-yttrium oxide, 25 parts of pure water, and 1 part of dispersant were stirred in a high-speed shear disperser at a speed of 1200rpm f...

Embodiment 3

[0043] The preparation method of embodiment 3 water-based MLCC special roller printing nickel paste, comprises the following steps:

[0044] S1, mix 1 part of hydroxyethyl cellulose, 0.5 part of hydroxypropyl cellulose, 0.5 part of hydroxypropyl methyl cellulose with 98 parts of pure water, heat to 45°C, and use a high-speed shear disperser at a speed of 1200rpm After stirring for 30 minutes in the middle, a water-soluble resin binder with a solid content of 2% was obtained;

[0045] S2, 84.5 parts of nickel powder, 14.5 parts of pure water, and 1 part of additives were stirred in a 1200rpm high-speed shear disperser for 5 minutes evenly, and then transferred to a 3000rpm nano-sand mill for grinding for 15 minutes to obtain a nano-nickel dispersion;

[0046] S3, 70 parts of nano-barium titanate, 2 parts of nano-magnesia, 2 parts of nano-yttrium oxide, 25 parts of pure water, and 1 part of dispersant were stirred in a high-speed shear disperser at a speed of 1200rpm for 5 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com