Water-based hydroxyl-containing polyester dispersion for automobile paint and preparation method thereof

A technology of hydroxyl polyester and hydroxyl polyacrylate, which is applied in the field of aqueous hydroxyl-containing polyester dispersion and its preparation, and can solve the problems of poor storage stability of resins and coatings, poor stability of trimellitic anhydride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

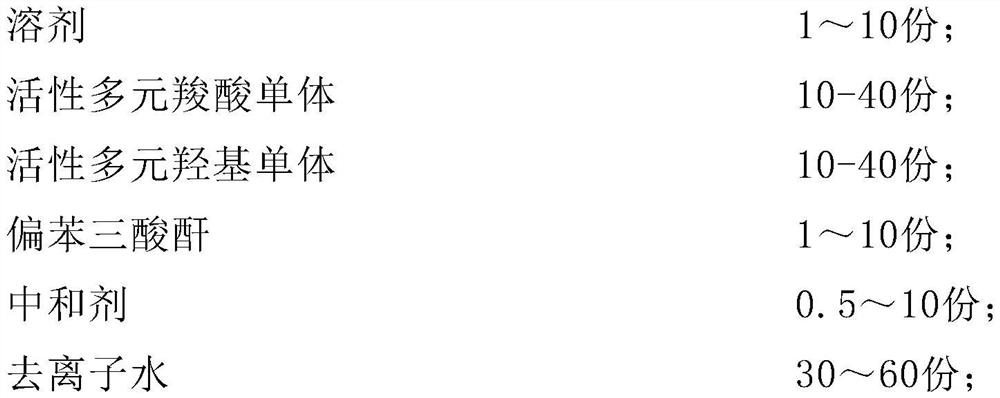

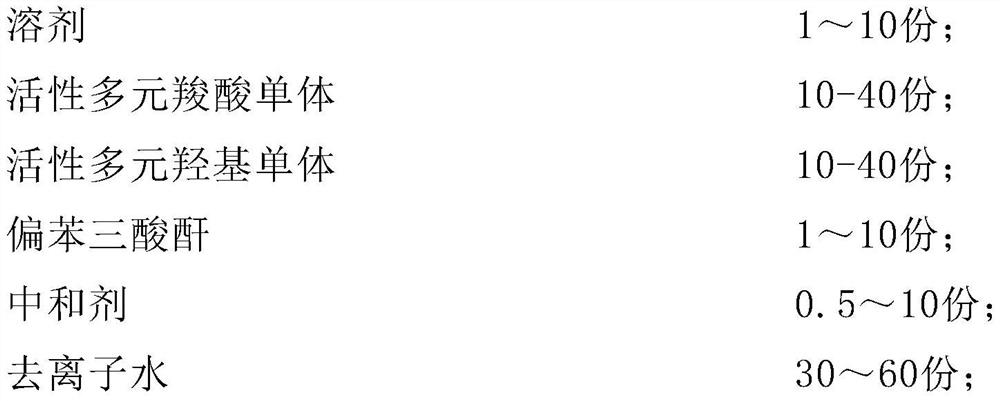

Method used

Image

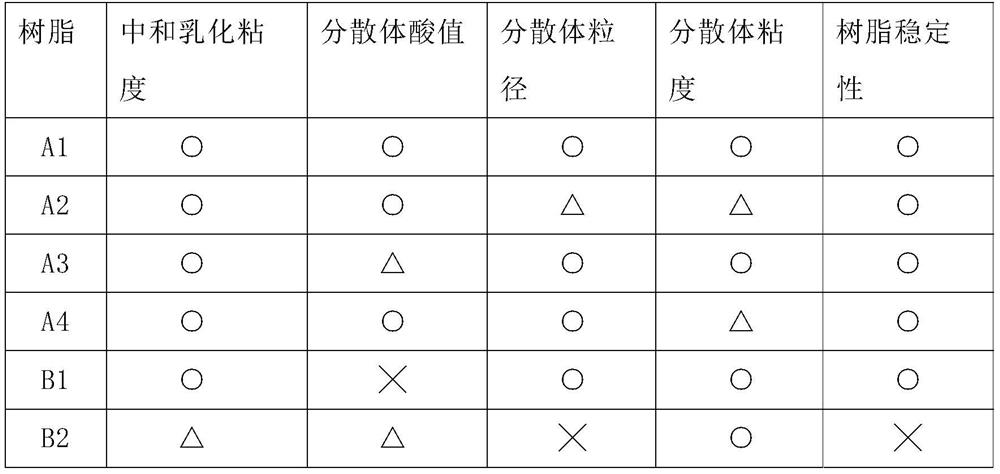

Examples

Embodiment 1

[0032] Add 73.3 parts of isophthalic acid, 158.6 parts of hexahydrophthalic anhydride, 173.7 parts of hexanediol, 49.3 parts of trimethylolpropane, 0.12 parts of monobutyltin oxide and a small amount of xylene into the reaction kettle for reflux, and heat up to 150°C Keep warm for 30 minutes, gradually increase the temperature to 200-220°C for 5 hours, check the acid value ≤ 3mgKOH / g, remove the reflux solvent xylene by vacuuming, and check the solid content ≥ 98%.

[0033] Then cool down to 160°C, add 24.1 parts of trimellitic anhydride, keep warm for 2 hours, check the acid value ≤ 35mgKOH / g, cool to 120°C, add 25 parts of dipropylene glycol methyl ether, and add neutralizer N, N- when the temperature is lower than 95°C 20 parts of dimethylethanolamine, keep warm for 30 minutes, add 500 parts of deionized water dropwise, heat up to 80°C and heat for 2 hours to mature, cool down to below 40°C and then filter out the material to obtain the solid content of 46%, the number avera...

Embodiment 2

[0036] Add 62.9 parts of isophthalic acid, 175.2 parts of hexahydrophthalic anhydride, 193.4 parts of hexanediol, 24.4 parts of trimethylolpropane, 0.12 parts of monobutyltin oxide and a small amount of xylene into the reaction kettle for reflux, and heat up to 150°C Keep warm for 30 minutes, gradually increase the temperature to 200-220°C for 5 hours, check the acid value ≤ 3mgKOH / g, remove the reflux solvent xylene by vacuuming, and check the solid content ≥ 98%. Then cool down to 160°C, add 24.1 parts of trimellitic anhydride, keep warm for 2 hours, check the acid value ≤ 35mgKOH / g, cool to 120°C, add 25 parts of dipropylene glycol methyl ether, and add neutralizer N, N- when the temperature is lower than 95°C 17.9 parts of dimethylethanolamine, keep warm for 30 minutes, add 500 parts of deionized water dropwise, heat up to 80°C and keep it for 2h to mature, cool down to below 40°C and then filter out the material to obtain the solid content of 46%, the number average molecu...

Embodiment 3

[0039]Add 131.2 parts of isophthalic acid, 115.4 parts of adipic acid, 197.3 parts of neopentyl glycol, 0.12 parts of monobutyltin oxide and a small amount of xylene into the reaction kettle for reflux, raise the temperature to 150 ° C for 30 minutes, and gradually heat up for 5 hours To 200-220°C, the acid value is detected to be ≤3mgKOH / g, the reflux solvent xylene is removed by vacuuming, and the solid content is detected to be ≥98%. Then cool down to 160°C, add 24.0 parts of trimellitic anhydride, keep warm for 2 hours, check the acid value ≤ 35mgKOH / g, cool to 120°C, add 25 parts of dipropylene glycol methyl ether, and add neutralizer N, N- when the temperature is lower than 95°C 16.7 parts of dimethylethanolamine, keep warm for 30min, add 460 parts of deionized water dropwise, heat up to 80°C and keep it warm for 2h to mature, cool down to below 40°C and then filter out the material to obtain the solid content of 46%, the number average molecular weight of about 2000, Hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com