Algae-proof coating composition and preparing process thereof

A composition and coating technology, applied in anti-fouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve the problems of air pollution, complicated operation, threats to human health, etc., and achieve good environmental performance and organic solvent. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Correspondingly, the present invention also provides a preparation method of the above-mentioned waterproof algae coating composition, comprising:

[0055] After mixing 20-50 parts by weight of epoxy resin and 5-15 parts by weight of active diluent, add 3-5 parts by weight of dispersant, 4-6 parts by weight of thickener, 10-15 parts by weight of Extender pigment, 30-40 parts by weight of water-absorbing pigment, 10-20 parts by weight of algae-killing pigment are dispersed at high speed, and 5-15 parts by weight of microencapsulated modified phenalkamine curing agent is added and dispersed at a low speed to obtain a waterproof algae coating combination.

[0056] Wherein, the microencapsulated phenalkamine modified curing agent is preferably prepared according to the following method:

[0057] Dissolving the modified phenalkamine curing agent in an organic solvent to obtain a modified phenalkamine curing agent solution;

[0058] Adding polymethyl methacrylate solution t...

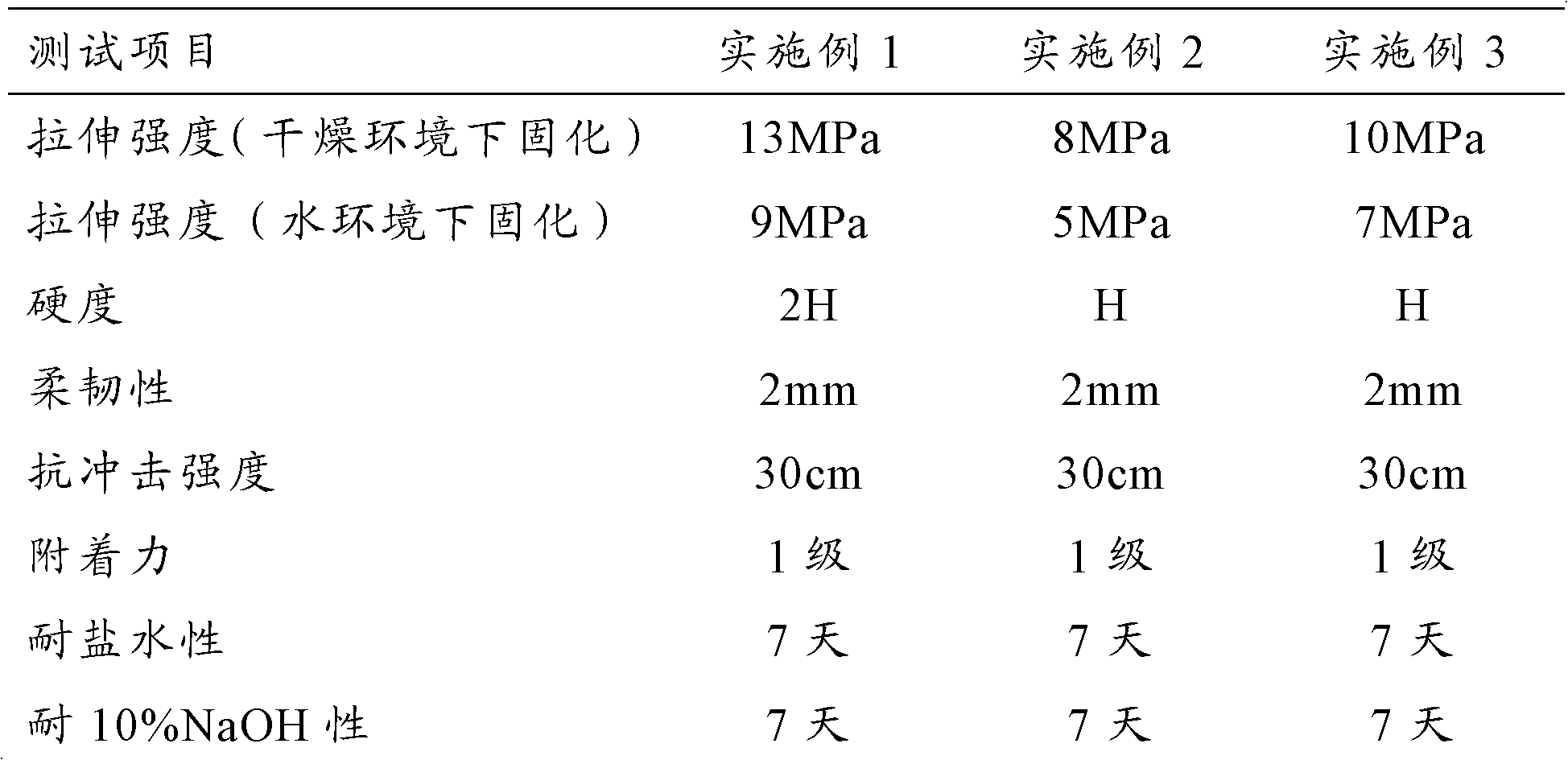

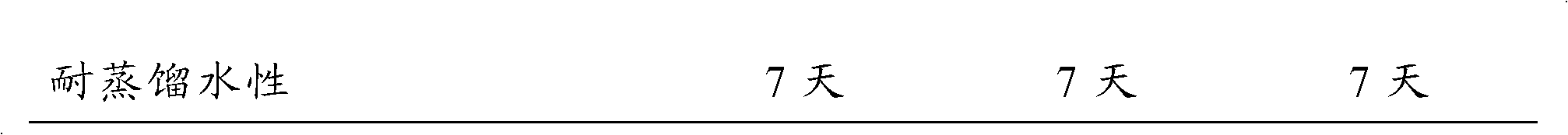

Embodiment 1

[0076] The components of waterproof algae coating are as follows:

[0077] 40 parts of hydrophobic epoxy resin, 1 part of defoamer, 3 parts of wetting and dispersing agent, 6 parts of thickener, 10 parts of reactive diluent, 7 parts of extender pigment, 8 parts of algae-killing pigment, 15 parts of water-absorbing pigment, micro 10 parts of encapsulated modified phenalkamine curing agent.

[0078] The preparation method of waterproof algae coating is as follows:

[0079] Add hydrophobic epoxy resin and reactive diluent first, then add wetting and dispersing agent, defoamer, thickener, extender pigment, water-absorbing pigment, and algae-killing pigment in turn while stirring, and perform high-speed dispersion, and then reduce the dispersion speed. And slowly add microencapsulated modified phenalkamine curing agent at low speed to disperse evenly.

[0080] Apply the waterproof algae coating prepared in this example directly to the wiped cement wall surface by brushing or roll...

Embodiment 2

[0082] The components of waterproof algae coating are as follows:

[0083] 20 parts of hydrophobic epoxy resin, 4 parts of wetting and dispersing agent, 4 parts of thickener, 12 parts of reactive diluent, 8 parts of extender pigment, 10 parts of algae-killing pigment, 37 parts of water-absorbing pigment, microencapsulated modified phenalkamine 5 parts of curing agent.

[0084] The preparation method of waterproof algae coating is as follows:

[0085] Add hydrophobic epoxy resin and reactive diluent first, then add wetting and dispersing agent, thickener, extender pigment, water-absorbing pigment, and algae-killing pigment in turn while stirring, and disperse at high speed, then reduce the dispersion speed and add slowly Microencapsulated modified phenalkamine curing agent dispersed evenly at low speed.

[0086] Brush the finished paint evenly on the glutinous rice paper for later use.

[0087] The paint prepared in this example can be directly carried out with water. When o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com