Environment-friendly waterborne epoxy resin emulsion and preparation method thereof

A water-based epoxy resin and epoxy resin technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of enhanced hydrophilicity of emulsions and affecting the water resistance of epoxy primers, so as to reduce energy consumption and save costs , The effect of reducing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

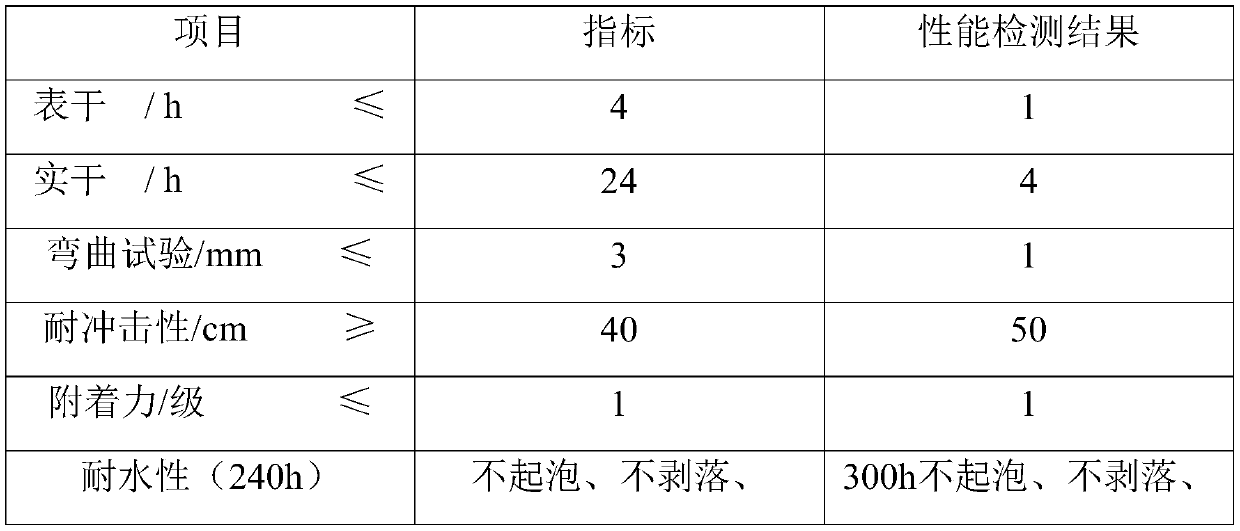

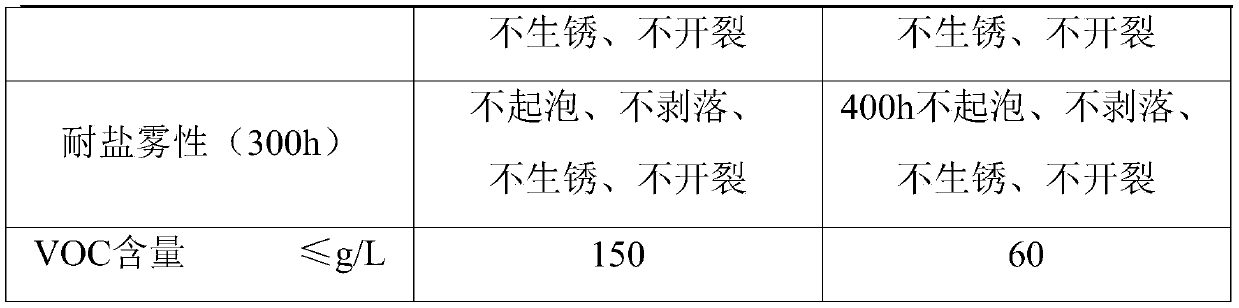

Examples

preparation example Construction

[0028] The preparation method of aqueous epoxy resin emulsion of the present invention may further comprise the steps:

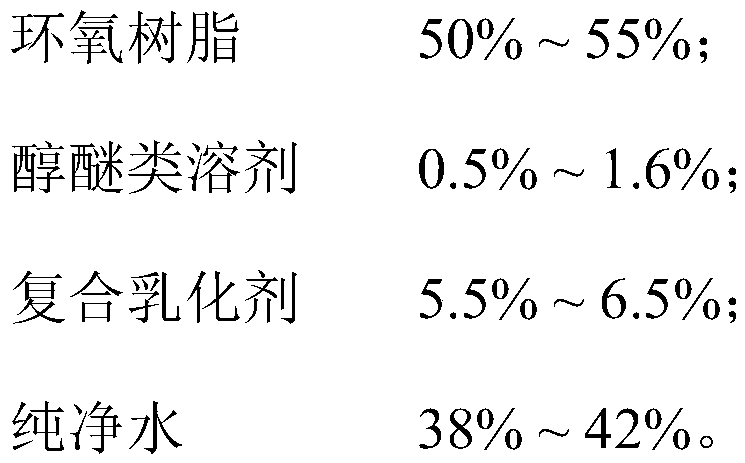

[0029] a) Heat treatment with a mass ratio of 50% to 55% epoxy resin (one or more of E20, E44 and E51) in a water bath at a temperature of 85 to 95°C for 35 to 50 minutes;

[0030] b) stirring and dispersing the heat-treated epoxy resin at a speed of 180 to 220 rpm;

[0031] c) Add 0.5% to 1.6% alcohol ether solvent (one or more of propylene glycol methyl ether, dipropylene glycol methyl ether, propylene glycol butyl ether and dipropylene glycol butyl ether) to the homogeneous epoxy resin mixture, and keep warm for 10- 20min;

[0032] d) Add 5.5% to 6.5% compound emulsifier (nonionic emulsifier Croda Chemical Shanghai Co., Ltd. 9107, 7101, Shenzhen Kaisite New Material Co., Ltd. EPR125 and anionic emulsifier Croda Chemical) to the obtained system Shanghai Co., Ltd. 7201 mass ratio is (24~40):1), continuous dispersion, rotating speed 280~330rpm, heat preser...

Embodiment 1

[0038] Accurately weigh 40% E20 epoxy resin (601 produced by Jiangsu Sanmu Chemical Co., Ltd.) and 15% E51 epoxy resin (128 produced by Nanya Electronic Materials (Kunshan) Co., Ltd.) in the formula and add in the there-necked flask, and heat in a water bath to Heat melting at 92°C and keep warm for 35 minutes. Turn on and stir to make it mix evenly, and the rotating speed is 210rpm, then add 0.55% propylene glycol butyl ether, the addition is 1% of the epoxy resin quality, keep warm for 15min, add 6.76% composite emulsifier (produced by Croda Chemicals (Shanghai) Co., Ltd. 9107 and 7201=24:1), the amount added is 12.3% of the mass of epoxy resin, the rotating speed is increased to 310rpm, after 37min of heat preservation, the temperature is lowered to 72°C, and 37.69% of water is added using a constant pressure dropping funnel; the water adding speed is controlled at 1.2 mL / min, keep warm for 50 minutes after the dropwise addition, then cool down to about 40°C and filter to o...

Embodiment 2

[0040] Accurately weigh 38% E20 epoxy resin (601 of Shanghai Yuanbang Resin Manufacturing Co., Ltd.) and 12% E51 epoxy resin (128 produced by Nanya Electronic Materials (Kunshan) Co., Ltd.) in the formula and add it to the three-necked flask, and heat it to 95 in a water bath. ℃ for thermal fusion, heat preservation 40min. Open and stir and make it mix evenly, the rotating speed is 180rpm, then add 0.5% propylene glycol butyl ether and dipropylene glycol butyl ether, the addition is 1% of the total resin quality of epoxy resin, keep warm for 10min, add 6.25% composite emulsifier (Wo 9107 and 7201 of Big Chemicals (Shanghai) Co., Ltd. = 40:1), the amount added is 12.5% of the total mass of epoxy resin, the rotating speed is increased to 280rpm, after 30min of heat preservation, the temperature is lowered to 75°C, and a constant pressure dropping funnel is used Add 43.25% water. Control the water addition rate to 1.5mL / min, keep warm for 60min after the dropwise addition, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com