Plastic anti-cracking coating process for domestic appliance

A technology for household appliances and coating technology, applied in the field of plastic anti-cracking coating technology for household appliances, can solve problems such as material cracking, and achieve good decorative effects, good mechanical properties, physical and chemical properties, and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Pearlescent water-based plastic coatings: alkali swelling thickener 1%, water-based acrylic emulsion 60%, additives 9%, KC110 pearlescent powder 6%, deionized water 24%.

[0032] White water-based plastic coating: alkali swelling thickener 1%, water-based acrylic emulsion 50%, auxiliary 9%, R980 titanium dioxide 25%, deionized water 15%.

[0033] Polish the defects of plastic PC with 1000 sandpaper, clean with 6# solvent oil, blow dust with high-pressure air flow, spray pearlescent water-based plastic paint on the bottom of the plastic back, level at room temperature, bake at 60℃ for 10min, the appearance and performance of the coating film For inspection, the back surface of the plastic is sprayed with white water-based plastic coating, leveled at room temperature, and baked at 55°C for 10 minutes to inspect the appearance and performance of the coating film. Silk screen, bake at 55°C for 2 minutes in a screen printing oven, inspect the appearance of the screen at room tempe...

Embodiment 2

[0035] Silver-white water-based plastic coating: alkali swelling thickener 1%, water-based acrylic emulsion 50%, additives 19%, water-based aluminum powder 5%, deionized water 25%.

[0036] For plastic PMMA defects, use 1000 sandpaper to polish, clean with 6# solvent oil, blow dust with high-pressure air flow, spray a single layer of silver-white water-based plastic coating on the back of the plastic, level at room temperature, and bake at 45°C for 15 minutes. Perform performance inspection, silk-screen, bake at 55℃ for 2 minutes in a silk-screen oven, inspect the appearance of the silk-screen, leave it at room temperature for more than 2 hours, and inspect and pack the appearance of the silk-screen.

Embodiment 3

[0038] White water-based plastic coating: alkali swelling thickener 1%, water-based acrylic emulsion 50%, auxiliary 9%, R980 titanium dioxide 25%, deionized water 15%.

[0039] For plastic ABS+PMMA defects, use 1000 sandpaper to polish, clean with 6# solvent oil, blow dust with high-pressure airflow, spray single-layer white water-based plastic coating on the front of the plastic, level at room temperature, bake at 55°C for 10 minutes, and check the appearance of the coating And performance test, silk screen, bake at 55 ℃ for 2 min in silk screen oven, test the appearance of silk screen, put it at room temperature for more than 2 hours, and inspect and package the appearance of silk screen.

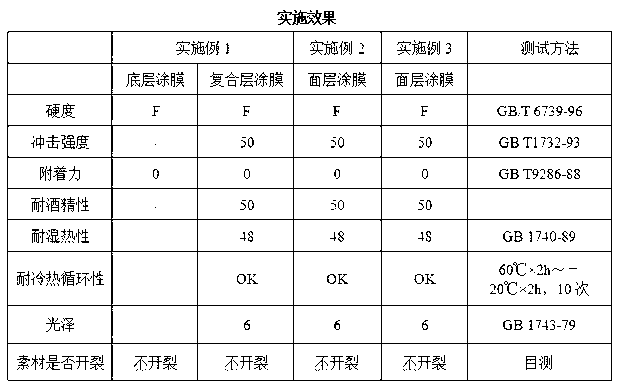

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com