Reactor for deep purification of drinking water and deep purification method of drinking water

A technology for deep purification and drinking water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the complex operation and management of water plants, increase process complexity and head loss problems, to achieve the effect of improving removal capacity and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

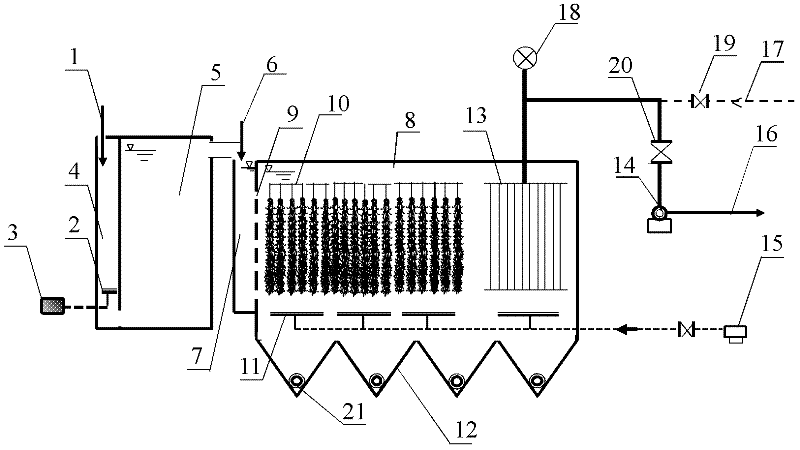

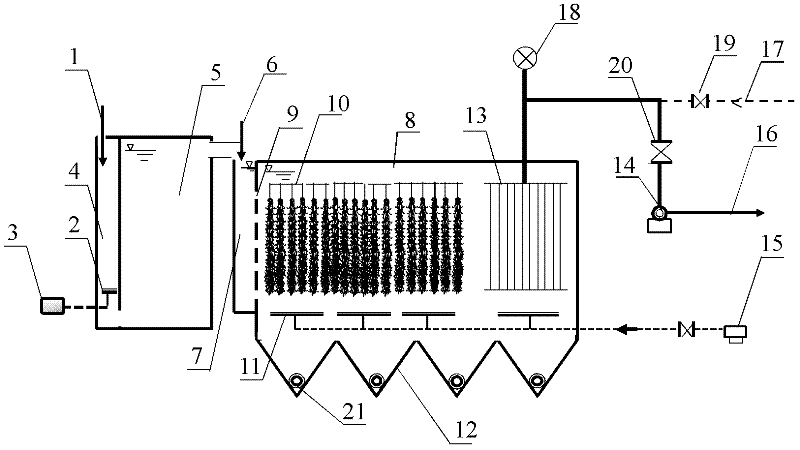

[0054] designed to build as figure 1 The shown reactor for the deep purification of drinking water; wherein, a biological oxidation unit is located between a main ozone oxidation unit and an ultrafiltration membrane filtration unit; the biological oxidation unit and the ultrafiltration membrane filtration unit set in the same reaction pool.

[0055] The main ozone oxidation unit includes two parts: an ozone contact tank 4 and an ozone reaction tank 5 .

[0056] A separator separates a container into the ozone contact tank 4 and the ozone reaction tank 5, and there is a gap between the separator and the bottom of the container; in the ozone contact tank The top of 4 is provided with water inlet 1, and the bottom is equipped with ozone aeration head 2, and described ozone aeration head is connected with ozone generator 3 by pipeline; The biological oxidation unit mentioned above is connected.

[0057] The biological oxidation unit includes biological filler 10 , aeration devi...

Embodiment 2

[0067] Design and establish the reactor for the deep purification of drinking water as in Example 1. The method of deep purification of drinking water using the above reactor is as follows: the water to be treated enters the ozone contact tank 4 from the water inlet 1, and the ozone generated by the ozone generator 3 is dispersed by the ozone aeration head 2 and then fully contacted with the water to be treated and dissolved to form Dissolved ozone, the hydraulic retention time of water in the ozone contact tank is 4 minutes, and then enters the ozone reaction tank 5 together to generate ozone oxidation reaction, and makes the hydraulic retention time of water in the ozone reaction tank be 20 minutes; The semi-soft filler is fixed in the biological oxidation unit, and the effluent from the ozone reaction tank 5 enters the steady flow area 7 of the reaction tank, and the water is uniformly distributed through the perforated plate 9 and then flows through the carbon fiber filled ...

Embodiment 3

[0072] Design and establish the reactor for the deep purification of drinking water as in Example 1. Design and establish the reactor for the deep purification of drinking water as in Example 1. The method of deep purification of drinking water using the above reactor is as follows: the water to be treated enters the ozone contact tank 4 from the water inlet 1, and the ozone generated by the ozone generator 3 is dispersed by the ozone aeration head 2 and then fully contacted with the water to be treated and dissolved to form Dissolved ozone, water has a hydraulic retention time of 3 minutes in the ozone contact tank, and then enters the ozone reaction tank 5 to generate an ozone oxidation reaction, and makes the water hydraulic retention time in the ozone reaction tank 15 minutes; the combination of activated carbon fiber material The filler is fixed in the biological oxidation unit, and the effluent from the ozone reaction tank 5 enters the steady flow zone 7 of the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com