High-density high-temperature heat-shrinkable pressure-sensitive tape and preparation method thereof

A high-density, pressure-sensitive tape technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of loose soil backfill, plastic deformation of the substrate, failure, etc., to achieve simple installation process, improved work efficiency, and anti-corrosion. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] By weight percentage, the formula is: high-density polyethylene (5000s) 72.0%; medium-density polyethylene (m3410) 9.5%; linear low-density polyethylene (FB3003) 15.5%; primary antioxidant (1010) 0.6%; Antioxidant (DSTP) 0.4%: black masterbatch, 2.0%.

[0033] 1. Weigh according to the formula according to the mass ratio, and after uniform mixing, pass through a twin-screw extruder to extrude the granulated material;

[0034] 2. Add the uniformly mixed substrate raw materials into the discharge port of the twin-screw extruder, extrude and granulate to obtain substrate pellets:

[0035] 3. The obtained high-density polyethylene substrate granulation material is dried and transported to the discharge port of the single-screw extruder, and then extruded and cut into semi-finished products;

[0036] 4. The extruded sheet is cross-linked by electron accelerator radiation and ready for use.

Embodiment 2

[0038] By weight percentage, the formula is: high-density polyethylene 65%; medium-density polyethylene 12%; linear low-density polyethylene 20%; primary antioxidant 10760.5%; secondary antioxidant DLTP 0.5%; black masterbatch 2%.

[0039] 1. Weigh according to the formula according to the mass ratio, and after uniform mixing, pass through a twin-screw extruder to extrude the granulated material;

[0040] 2. Add the uniformly mixed substrate raw materials into the discharge port of the twin-screw extruder, extrude and granulate to obtain substrate pellets:

[0041] 3. The obtained high-density polyethylene substrate granulation material is dried and transported to the discharge port of the single-screw extruder, and then extruded and cut into semi-finished products;

[0042] 4. The extruded sheet is cross-linked by electron accelerator radiation and ready for use.

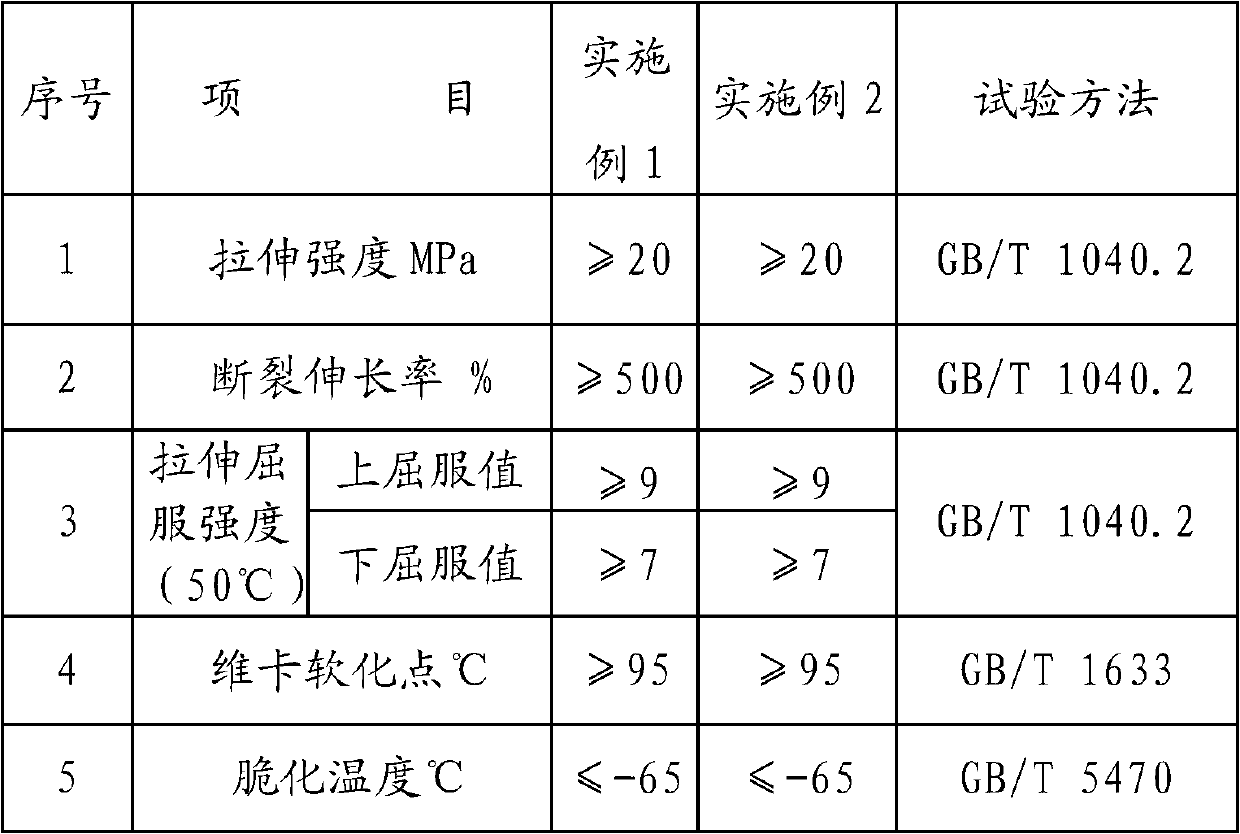

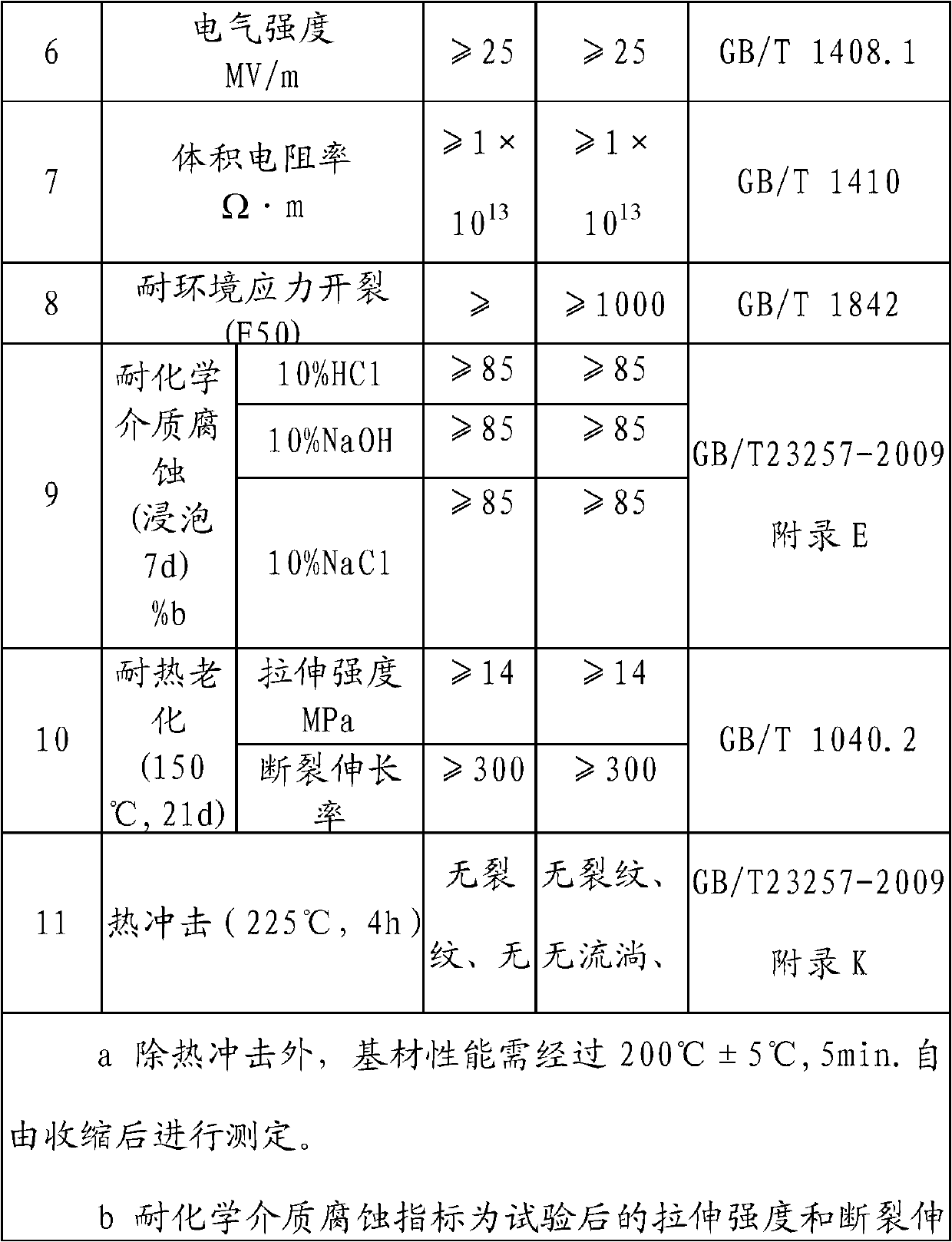

[0043] The pressure-sensitive tape substrates obtained in Examples 1 and 2 were subjected to performance tests,...

Embodiment 3

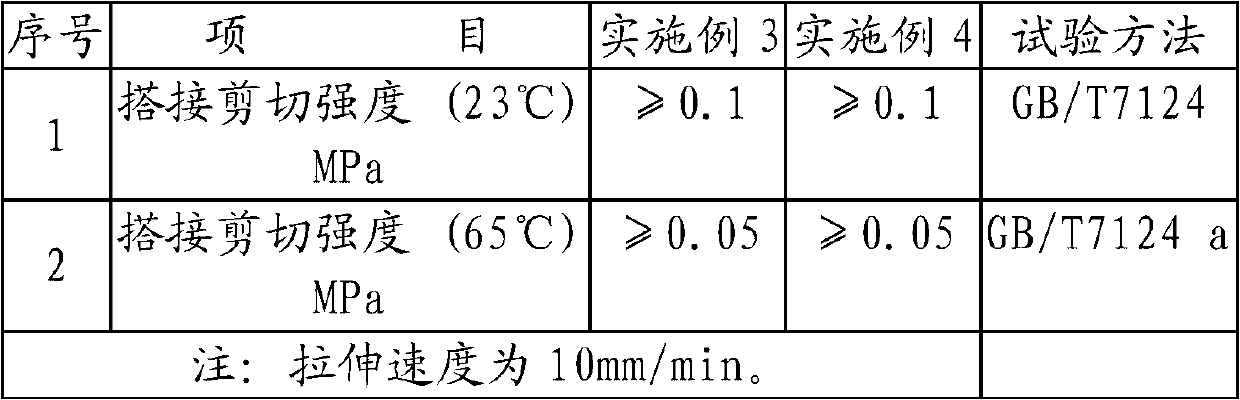

[0049] By weight percentage, the formula is: butyl rubber (IIR268) 7%, high molecular weight polyisobutylene (PIB100) 13.5%; medium molecular weight polyisobutylene (PIB50) 15%; low molecular weight polyisobutylene (PIB6240) 10%; tackifying resin (Terpene T-100) 12.5%; barium sulfate, 40%; antioxidant (1010) 1%; antioxidant (268) 0.5%; black masterbatch 0.5% and mix well. Mixed by a kneader to make cement; then the uniformly mixed cement was transported to the discharge port of the extruder by a gear pump, extruded and coated on the base material obtained in Example 1, and pressed into a finished product. Among them, the thickness of the substrate is 1.2mm, and the thickness of the adhesive layer is 1.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com